This popular article was originally published in the Aug. 9, 2017 issue of Radio World Engineering Extra.

Lately, the buzz in radio work has addressed the ability, the desirability, the necessity, the pain and the ecstasy of fixing the gear that makes the station go.

On a personal level, in my arrogant youth (that would be pre-70), I thought I could fix just about anything except, possibly, broken hearts. In my maturity, however, I have moderated that hubris and feel that I can fix most everything. As we all know, there are always exceptions, such as the occasional flood-damaged, lightning-struck or coffee-penetrated gear that is beyond redemption.

Still, it gives me great joy to resurrect basket cases to as good as or better than original performance.

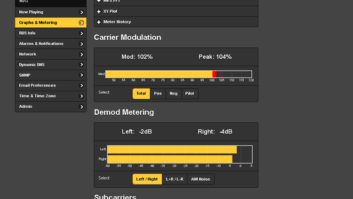

One area of success has been with modulation measurement equipment, and I’ve enjoyed particular success with a subsection of that genre: second-generation FM monitors.

A special case was a Belar FMM-1 generously given to me for essentially spare parts. In its travels, it had experienced a close encounter of the floor kind, making a one-point landing on its face and shattering the very expensive meter bezel assemblies of the frequency offset and modulation meters.

(We’ll leave out my rebuilding of these bezels with new Plexiglas faces, etc., as that effort is just a profile case of masochism!)

Band Saw

To compress a long and, at first, frustrating troubleshooting exercise, the core problems were identified.

One problem was a bad low-pass filter that follows the pulse-counting demodulator. On the band saw, I was able to cut the sealed can open and found a four-section LC circuit (Fig. 1). One of the inductors (obviously in the series arms as is a low-pass) was open. Dealing with that part, I was able to restore the action of the filter that effectively passes just signal components below 225 kHz.

Incidentally, the filter is definitely not bidirectional and appears to present a different load at each port. For this reason, be sure to mark the chassis position and wire connections carefully if you have to remove the filter.

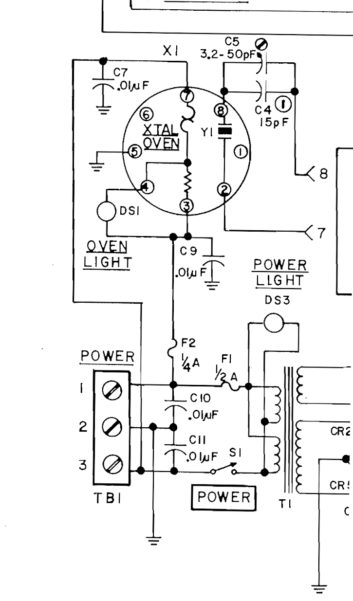

A second problem was that the local oscillator never got close to the frequency indicated on the crystal. The oven where this local oscillator crystal resides never even got warm. “One wonders if this could be the problem,” he says to no one in particular in the empty shop!

This unit has a really first class (big dollars) crystal oven that, when you go inside, appears to be a machined core with areas cut out for the temperature-operated heater control switch, the actual heater element and the crystal. The model of oven in the Belar monitor runs on 120 volts AC and operates whenever the unit is plugged in to keep the unit ready for precision measurements whenever the monitor is turned on.

The oven has an octal tube-type base, so popping out this item to troubleshoot is easy. Troubleshooting revealed that the control switch was non-operative.

As the switch seemed to have been positioned in the oven body by “sweating” in the factory, getting it out was not an option.

Many of us have some of those crystal ovens left over from the two-way days of early Marti, GE Progress Line and Aerotron equipment, and I had an especially good one that was capable of operating on up to 12 volts. Here’s an indication of how old it is/was — my oven could operate on either 6 or 12 volts! When did you last own a vehicle that was 6 volts?

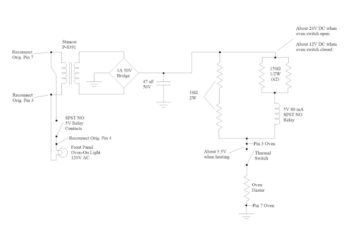

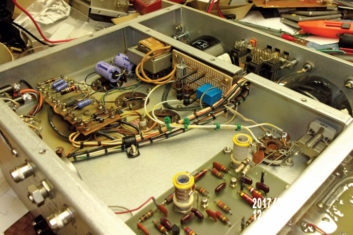

The original circuit for the 120 V oven is shown in Fig. 2, and my replacement circuit is shown in Fig. 3. Fig. 4 shows the location of the PCB and components indicated in Fig. 3 after retrofit installation.

The new circuit accomplishes two goals: The 5 volts impressed across the heater smooths out the hysteresis, stabilizing the temperature window and resulting in closely maintaining the local oscillator at its optimal frequency point; and we can still use the front panel 120-volt “heater on” light as installed.

The “new” oven luckily had a crystal position that matched the Belar wiring, and it was the FT-243 type, so no oscillator circuit socket changes were needed. We used the 120 V AC wire connections on the socket and reconnected them to our little PCB. The Stancor transformer fit perfectly inside the Belar unit, providing 12 volts of DC when loaded, and although everything gets a little warm, there are no heat problems.

It Works!

After warm up, the local oscillator came into adjustment range, and after the usual ESR exercise to replace bad electrolytics, the monitor now works really well. Most impressive is that the audio out for performance evaluation is in the range of 0.33% THD at 400 Hz, which is about the limit of the HP audio generator’s specification.

Now, if I can just find someone to rework the modulation meter, as the mechanism is sticky from its rapid deceleration when the floor raced up to it, this FMM-1 can go back to work.

Incidentally, the frequency offset indication is quite good. Moving the HP generator 1 kHz up or down from the carrier at 96.9 MHz produces an almost exact 1 kHz offsets on the meter.

The balance of today will now be given over to fixing broken hearts, washing machines, programming the cable box and more important items than broadcast gear.

Charles “Buc” Fitch is a registered professional consultant engineer, senior member of the SBE, lifetime CPBE with AMD, licensed electrical contractor, former station owner and former director of engineering.