Photo

(click thumbnail)Fig. 1: Cycle the sump pump to prevent flooding like this.

(click thumbnail)Fig. 2: Repurpose a Burk AC-4 and IO-8 to reset the pump for more reliable operation.

(click thumbnail)Fig. 3: This temporary lashup of the AC-4 ensures a dry basement.

(click thumbnail)Fig. 4: A contractor’s ladder looks innocent enough …

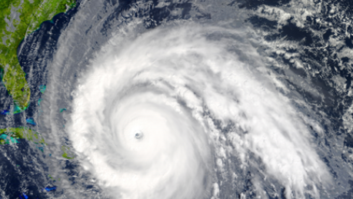

(click thumbnail)Fig. 5: But in front of the STL dish?Much of the East Coast endured torrential rains this year, followed by hurricane season.

In July, Nathan Chervek, assistant chief engineer at the New Hampshire Public Radio cluster in Concord, N.H., faced a storm like no other. After 12 inches of rain fell over the weekend, the walls in the basement were really weeping.

The cluster soon had its very own water park in the basement, as seen in Fig. 1. There were 1 to 3 inches of rain in the basement at one time or another.

The building has a sump pump, but Nathan discovered that its operation was erratic. It turns out the pump would pump faster than the water was flowing into the basement. When the water level got too low, the pump would vapor-lock and stop pumping.

A simple power cycle was all it took to get the pump back up and pumping. But although this cycling could be done manually, the staff was having problems with the pump locking up overnight.

The solution came in the form of a repurposed Burk AC-4 Remote Outlet Controller, seen in Fig. 2, and a spare IO-8 (which was replaced by a shiny new IO-16 to upgrade the main Burk system). The AC-4 provides a quick and easy control interface to AC outlets.

Nathan programmed the “timed events” set to do a 20-second momentary “off” every half hour. That’s all it took to keep the pump running reliably, and ensure a dry basement. Interconnect of this temporary setup doesn’t have to be fancy but it gets the job done.

* * *

Dennis Snyder is the market engineer for the Hall Communications five-station cluster in Burlington, Vt. His boss is Vice President of Engineering Edd Monskie, who writes that Dennis noticed that once a tank of nitrogen started to get below half-full, the line pressure would rise.

Dennis investigated the problem and found it was due to the regulator. He found a two-stage regulator that worked better. It is manufactured by Harris Calorific Inc. (not the broadcast Harris) and is model number 9200NC.5psi.

The maximum output of this regulator is only 5 psi, so it is easy to regulate the line pressure to anything up to 5 pounds. This new regulator ensures the pressure never goes any higher than 5 psi for the life of the nitrogen tank.

Dennis says the cost of the regulator was covered easily by the savings in using less nitrogen, because the tanks last longer. Of course it does not mount to the wall like the one pictured in the Sept. 1 Workbench column; but Edd says each individual will have to decide which is the best choice for his or her site.

For an interesting tutorial on how single- and two-stage regulators operate, visit www.harriscalorific.com/2003/regulatorselectionguide.asp.

* * *

Fig. 4 might raise a few eyebrows, but maybe not, since it’s a fiberglass ladder.

Fig. 5, on the other hand, should really get readers to sit up and take notice. A ladder in front of an STL dish is a good example of why your studio rooftop access needs to be controlled. Contractors roaming around on the roof can cause all kinds of damage to antennas and transmission line, not to mention themselves.

Show this picture to your building engineer and make sure that proper precautions are taken whenever anyone is on the roof. No names or calls – this could happen anywhere.