Jerry McCarty spent more than three decades at the college of engineering at the University of Michigan. He handled the technical end of its distance learning program, starting out with Instructional Television Fixed Services microwave, then migrating to videotape delivery and some videoconferencing. Along the way, they picked up a Ku Band uplink, which is still in use for occasional news feeds to the national networks.

During Jerry’s 34 years there, he was a part of two major moves, both of which required the buildout of new facilities. It goes without saying that Jerry soldered a lot of connectors.

He saw our May 8 tip on soldering XLR connectors and wrote in to say that he loves the idea of using a clipboard to hold connectors down.

Jerry also sent a photo of his version of the wood block discussed in that column, to hold connectors in place — see Fig. 1. This one has to be at least 25 years old, and includes connectors for holding DB-style plugs. Jerry’s adaptor has served the staff well, especially with the added notations for those who can’t see the pin numbers on DB-style connectors anymore!

If you build one of these, maybe include the wire color and polarity on the XLRs — remember, Pin 2 flips from one side to another depending on the sex of the connector! The project shouldn’t take more than a couple hours to build, and cost is minimal. Jerry adds that the coffee stains are optional.

Since retiring from Michigan, Jerry got involved building an AM/FM station and still does some work there and at the university.

***

I’m always amazed at the finds that project engineer Dan Slentz comes up with. His latest is from Walmart. Its online store is selling acoustic foam panels; a 96 count pack of 12 in. x 12 in. x 1 in. squares is about $96. Smaller combinations of the panels are available.

Putting together a small podcast studio? A six-pack of the same dimensioned panels is $10! Head to www.walmart.com and enter “acoustic foam panels” in the search block.

The only review stated that the buyer ordered black and got grey panels — there’s apparently no way to specify color, though the site says color choices are available. If you don’t care what color you get, this option may be for you.

***

When consulting engineer Charles “Buc” Fitch, P.E., isn’t fixing things, he’s cleaning up his shop. Buc sent along a few pictures of what he found in one of his part bins.

About 10 years ago, Buc repurposed a maritime mobile VHF two-way into a base station for a weather station for Honduras. He modified the receiver to monitor the outgoing transmission and made some more mods to the transmit side for continuous operation.

The output was about 10 watts (which covered the local village) and was one of the first of the NOAA weather channels. It was called Weather Channel One or WCO. At the time, the folks living there used a lot of “family radio walkies” that had NOAA channels on them. So WCO was a great way to get out not only information about the weather, but community announcements, as well.

While cleaning up the shop, Buc came upon the carcass of a second unit that he harvested for module spares. Upon careful inspection, Buc found these nifty “knurled nuts and bolts,” shown in Fig. 2. Someone had secured the top shroud cover with “quick-off” bolts. Buc thought these had come this way from the manufacturer.

It turns out that some innovative engineer or tech person had taken the supplied screws and modified them to this nifty fix. These knobs, which were glued to the top of the screws and seen in Fig. 3, were actually weather-beaten and crudded-up U.S. quarters. In an area where tools may be scarce, the serrations along the edges of the quarters added substantial friction for quick removal of the unit top — without tools!

[Repurposed Gear Adds Missing Console Features]

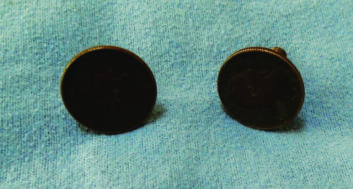

After cleaning up the knobs with a little buff wheel included with Buc’s latest Dremel-brand tool (Fig. 4), you can see they are 1970 and 1973 quarters. The finished product is neat, simple, easy and inexpensive — even accounting for the 50 cents for the quarters.

Seeing the shiny quarters made me think of Buc’s next project: homemade quarter cufflinks! Stand by.

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips and high-resolution photos to [email protected].

Author John Bisset has spent 50 years in the broadcasting industry and is still learning. He handles western U.S. radio sales for the Telos Alliance. He is SBE certified and is a past recipient of the SBE’s Educator of the Year Award.