The hornet nest that Harry Bingaman discovered in the attic of his transmitter building, pictured in the May 23 Workbench, is just the start of the season of bees, it seems.

Greg Davis, Beaumont/Houston market engineer for Cumulus, encountered a honeybee nest recently, but these were not your typical honeybees.

After the swarm chased him to his car, stinging him a dozen times, the company called in a professional beekeeper. When the beekeeper got within 50 feet of the nest, he was covered with the aggressive bees.

One of the bees collected tested positive for being 26 percent Africanized honeybee. While these bees were discovered in Texas in 1990, they were found in the southeast part of the state in 2001.

The local Beaumont Enterprise newspaper covered the event and also has a link describing what to do if you are attacked. If you work in an area that has become a habitat for these bees, you’ll find some of the tips listed in the article useful.

Visit http://www.zwire.com/site/index.cfm?newsid=18328307&BRD=2287&PAG=461&dept_id=512588&rfi=8

Greg Davis is the “electrician” referred to in the article and can be reached at [email protected].

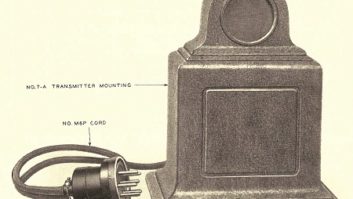

(click thumbnail)A label placed directly on the breaker makes identification easier.

* * *

Electricians will usually fill in the circuit breaker labels on the inside of the breaker box door, but good engineering practice will take that a step further.

Bob Drazba, a member of the engineering team at the Entercom Scranton cluster, used an electronic labeler to label each transmitter breaker. Seen in Fig. 1, the breakers can be identified quickly.

The market chief of this cluster, Lamar Smith, also sent a couple of pictures of a new transmitter facility that he and his team completed. Fig. 2 shows that all the lines are level; it’s a pristine layout.

So how do you get everything to look so pretty?

A laser leveling device, which shoots a laser beam along the length of a conduit or rigid line run, is ideal for implementing the components in a project of this type. But Fig. 3 shows another, less expensive trick. Use temporary hangers made out of a heavy gauge of copper wire to adjust conduits or rigid lines until they are level.

After all the lines are run and everything is plumb, permanent hangers can be installed. Until then, if something needs to be adjusted, simply remove and re-bend the copper wire “hook.”

(click thumbnail)Level electrical and RF plumbing for a neat installation.

Note that Lamar wire-tied a protective cover to protect the temporary hook from scratching the copper line. It’s the little things like this that make a facility shine.

* * *

The hot summer is when we need air conditioning the most; but with all the humidity sucked out of the air, condensate drains can fail.

For ceiling-mounted air handlers, an overflow can make an engineer’s life miserable. Heavy storms can lead to roof leaks, further complicating your life.

Marc Mann of San Diego sent in a couple of links that could help solve these indoor downpours should they occur. The first device is a Roof Leak Diverter. This is a waterproof square of plastic, designed to be hung under the leak, using reinforced corner eyelets.

(click thumbnail)Heavy-gauge copper wire can be used to temporarily hang lines, ensuring straight runs.A garden hose connector is mounted to the center of the plastic sheet. Once the sheet is hung under the leak, a garden hose can be connected to direct the water outside, into a bucket, or to an indoor drain.

Marc has kept one of these Diverter kits as an insurance policy, and this has paid off handsomely in the past.

As with all good products, they are improved upon; the most recent addition is a drop-in 2×4 foot acoustical ceiling panel that is actually a water leak collector. The one Marc found comes with 25 feet of hose, ceiling clips and hose hangers. The Diverter kits come in different sizes, to match your studio tile size. If you maintain studios, consider picking one of these up.

Global Industrial stocks a variety of these kits. Head to www.globalindustrial.com and search for “Roof Leak Diverter” and “Ceiling Panel With Drain.”

The Global Industrial site that Marc suggested will grab your attention. Lots of really cool stuff that engineers can use. Got a Web site that you’d like to share with Workbench readers? E-mail the address to me, along with a few words on why you find it useful. I’m at [email protected].

* * *

David Otey is a CPBE and general manager of Azcar Training Systems. He enjoyed the stories about Kevin Larke and Dave Doherty and their creative use of iPods/MP3 players. Both engineers suggested using these devices as a source of test tones or even emergency programming.

However, David raises a good point that these devices could not be used to source white or pink noise. David writes, “Ever try to compress noise?”

Noise, by definition, is uncorrelated to anything, so it can’t be compressed. That’s why it’s so important to keep your audio and video as noise-free as possible in advance of any digital coding stage. Thanks for the clarification, David.