I’ve never seen so many stations filing for and building FM translator sites. If a translator is in your future, these tips from iHeartMedia’s Dave Agnew will be helpful.

Fig. 1: Why not build that translator rack in your shop rather than on site?

Fig. 2: This compact computer drive has lots of uses. You may remember Dave from his many years at Harris, working in field service and then as an applications engineer with the FM product line. Given that experience, you know his facilities are going to be built right. This starts with planning and selecting the location of the build.

Dave’s cluster is in Aurora, Colo., near Denver. Mountaintop sites aren’t the most forgiving for construction, so Dave pre-builds his equipment racks in the warmth of his engineering shop. Pre-wiring speeds installation; by following a “template” for equipment, all the sites are similar. This speeds troubleshooting and reduces spare parts counts.

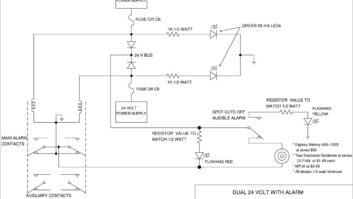

Fig. 1 shows a rack Dave is working on. This is a two-translator project; open spaces are for gear that is already in operation for the first translator. The equipment seen here includes, from top, an Omnia.7 processor, Audemat RDS encoder and Broadcast Devices switch controller, used as a main/alternate main controller and connected to a four-port MCI 61101-N RF switch. Finally, there are two Nautel VS300 FM transmitters in a main/alternate configuration.

Pre-building makes good engineering sense, especially if you’ve tried to solder or wire in the cold! Another benefit is that all the parts and supplies needed are there in your shop. Dave writes, “You can do much better work in a nice environment, and that translates to better reliability and fewer trips to the site.”

Knowing Dave, when his project is completed, he’ll add a schematic or block diagram to the door of the rack, so if another engineer needs to troubleshoot in Dave’s absence, the process is more efficient.

*****

Dave also asked if I’d seen the small hand-held-sized solid-state computers like the one shown in Fig. 2. Its small size makes it ideal for utility purposes; with no moving parts, it’s great for the transmitter site.

This particular model is an Intel NUC, Model NUC5i5MYHE costing less than $500.

*****

Ryan Hanna handles engineering for Broadcast South LLC in Georgia. Recently, one of its stations experienced failure of a 900 MHz STL receiver and no backup was available.

To act in its place, Ryan pressed into service a computer, an eBay Chinese USB TV receiver chip dongle and some freeware. This is strictly a temporary setup until the receiver gets back from repairs; but it shows what you can scrape together in a pinch to get a station back on the air.

Ryan is a ham radio operator and has tinkered with everything within his realm of knowledge. These little receiver dongle are made to be wideband digital TV receivers.

“Someone much smarter than I modified the drivers for the software and turned the dongles into ultra-wideband SDR (software-defined radio) receivers,” he writes.

There are several different models out now, and they can receive so much: TV, SSB (single-sideband), AM, FM wide or narrow — you set the bandwidth. As we described in a Workbench column in January, New Hampshire Public Radio’s Steve Donnell showed how these dongles can even function as spectrum analyzers, although not entirely accurate. Yes, the dongles have just as many cons as pros, but they work great to keep a station on the air.

Fig. 3: Use this hook-and-loop strap to keep wallwart supplies in place. *****

You may have used tie wraps to hold “wallwart” power supplies on a vertically mounted power strip. A good idea — but if you have to remove the wallwart, you must snip the tie wrap. In an emergency, removing the mounting tie wrap takes time.

A company named CPI makes a Velcro-brand hook-and-loop assembly with mounting eyelet. It’s called a SAF/T/GRIP. The strap portion is 12 inches long and the strap will make up to a 4-inch diameter loop. The SKU is 05012-201. Online distributor Surplus Trading Corp. (www.surplustrading.com) can provide pricing. Enter 05012-201 in its search field.

In addition to securing wallwarts, the mounting eyelet allows you to secure the strap to long microphone cables or extension cords from your remote kit. The hook-and-loop strap won’t get lost and turns a snarled box of wire into neat bundles.

*****

We close with some sad news. Jeff Griggs, a field service engineer at Harris/GatesAir, passed away recently. Readers of this column who maintain Harris/GatesAir transmitters more than likely had contact with Jeff as he provided decades of telephone factory service to broadcasters around the world. From 3 a.m. calls to help someone with an SX5 that was off the air, to teaching a class on maintenance of the HT25 in Kuwait, to managing the installation, commissioning and follow-up service for a 2 Megawatt medium-wave DX transmitter for the Voice of Vietnam, Jeff did it all.

Jeff loved broadcasting, and we’ll miss him. We offer our condolences to his family.

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips to [email protected]. Fax to (603) 472-4944.

Author John Bisset has spent 46 years in the broadcasting industry and is still learning. He handles West Coast sales for the Telos Alliance. He is SBE certified and is a past recipient of the SBE’s Educator of the Year Award.