Tim White, market engineer for the Clear Channel cluster in Sarasota/Bradenton, Fla., writes about a transmitter that had a nasty habit of blowing a power supply module every time there was a bump in the AC power.

Tim was pretty confident it wasn’t the transmitter; and in December, he had 2-1/2 days to investigate as the tower lights, conduit and cable were completely replaced and the site was down.

(click thumbnail)Fig. 1: Check for corroded lugs behind electric panels.Tearing into the building’s electrical system, he found a large unfamiliar box in the middle of the AC feed to the transmitters. Labeled the “Kleen Line Filter,” its purpose was to eliminate transient energy.

All three orange lamps glowed on the front of the box. Inside, the fuses never blew, so no one ever took the cover off the device.

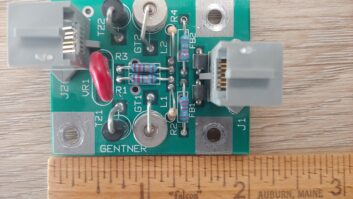

Once inside, Tim noticed a loose lug on one of the inductors, shown in Fig. 1. Pretty ugly; but when the lug was removed, the condition of the wires was even uglier, as seen in Fig. 2.

Tim removed the box completely, and the score is several thunderstorms (with lots of power bumps), and the transmitter runs beautifully — like he knew it would. Isn’t it funny how a piece of loose hardware can cause 30 years of heartache?

* * *

(click thumbnail)Fig. 2: Damaged wires after removing the lug.

The following device is a little pricey unless you have lots of temperatures to monitor, but the company has a broad line of products that may be useful to the broadcast engineer. Check out www.cyberresearch.com.

The company is known for rugged industrial PCs. They have just completed a series of modules that connect directly to temperature detectors and send the results back to your PC via the 2.4 GHz radio band. Gone are the troubles associated with long-distance cabling.

The maximum distance for clear communication depends on building construction and on the number of intervening walls, but 30 meters is typical. Visit the site, you may come up with an interesting application.

* * *

OK, I admit my age is showing. Steve Schuh wrote to remind me that the National Electrical Code does not permit running wire across the top of dropped ceiling panels. I know this, and should have added that the motorized car simply transports the cable — which should be plenum rated.

After the wire is run, Steve clarifies that it needs to be secured above the panels. If there aren’t enough pipes or ducts to keep it up and out of the way, it must be fastened to the structure.

According to the Minnesota inspectors, this means you cannot fasten the wire to the ceiling support wires. You can use support wires as long as you add the support wire and tag it as being installed by the electrical installer as a support wire.

Steve points out that there are other interesting codes as well. One example is that you are not allowed to tie your cable to the outside of electrical conduit unless it is a conduit provided for communications wiring and not power.

Another requirement is that any communication cable must be “listed.” Yet another requirement is to remove any abandoned cable. This means that if cable is installed that is not in use, it must be tagged on each end designating it as a “spare” for future use, or it must be removed.

I think readers are beginning to see why electrician’s rates are so high! That NEC code book is full of amazing, and hard-to-interpret, language.

(click thumbnail)Fig. 3: Simple hardware prevents flying projectilesIn Minnesota, Steve is required to have a technology contractor license in order to install wiring as a contract engineer. To get the contractor license, he must have at least one full-time licensed Power Limited Technician, and he or she must be on the job site and can supervise no more that two additional installers.

In addition, Steve is now required to take 16 hours of code training every two years to renew his license. In Minnesota, the licensing agency is the same agency that licenses and regulates the electrical contractors.

It’s apparent the codes are catching up with us in the radio business, and Steve thinks that is a good thing. Years ago when Steve and I started in this business, it wasn’t unusual for me to find lamp cord carrying 115 volt AC run around buildings for warning lights and other control uses — even Belden 8451!

* * *

(click thumbnail)Fig. 4: The new bolt and nut cap keeps everything secure on this LPB Mike Boom.

John Sims of RF Specialties of Missouri sends in this tip from his good customers at Entercom Kansas City.

They have had a problem with a spring mounting stud on the LPB Silent Boom mic arm coming loose. When this happens, the stud becomes a projectile flying across the room — in the general direction of the talent!

Assistant CE Kirk Chestnut and his crew came up with a solution to the problem, pictured in Fig. 3, using common hardware store parts. An 8-32 thumb nut and pan head machine screw now securely hold the springs, as seen in Fig. 4.

If this assembly still comes loose, I imagine you could use those locking nuts, with the plastic inserts, too.

Visit the RF Specialties Web site at www.rfspec.com, where you’ll also find some useful free engineering software.