David Morgan, CBRE, is director of engineering for Sinclair Telecable Norfolk. He took advantage of early spring-like weather to have all the AM towers in his cluster inspected.

While his sticks are being looked at, David uses the opportunity to inspect and clean his antenna tuning units at the base of each tower, either in Kintronic weatherproof cabinets or in small block buildings.

Here are some tips from David. His process begins with a series of safety precautions.

First, throw the transmitter breakers or, in the case of an AM directional, feed the furthest tower to run non-directionally at reduced power.

Before you work inside an ATU, use car battery jumper cables to short or ground the tower to the base ground strap. This is for your safety and that of the tower climber.

Next pull the J-plug between the tower and the tuning apparatus for extra isolation.

As a further precaution, David uses packs of good, brightly colored alligator clip leads, available from Amazon, to ground everything inside the ATU. The bright colors reduce the chance that you’ll leave one attached accidentally. If a distant tower in the directional array is transmitting non-directionally — even at reduced power — the near-field RF can bite you!

Wear a hard hat when anyone is on the tower. Not only might someone drop a tool, but it’ll protect your head when you’re working in the tight spaces inside an ATU. (David says this has saved him more than one headache from whacking into something with his skull.)

Begin your thorough cleaning process by donning a pair of gloves and a mask. You can’t be too careful. Then give the interior a good vacuuming, using either a battery- or AC-powered vacuum. Ryobi and others make cordless wet/dry vacuums that are ideal for this purpose and can be found at the big box stores.

It’s amazing how many bugs can get into the ATU, only to die. And not just bugs. So before you vacuum, use a strong light to look for mouse excrement. If mice are getting into the ATU, try to determine how. Look for ill-fitting covers, gaps or holes, and repair them.

[Read Another Workbench by John Bisset]

You might also place a pouch of Bonide Mouse Magic on the floor as a stopgap or insurance measure. You’ll find this product sold online as well as at garden centers.

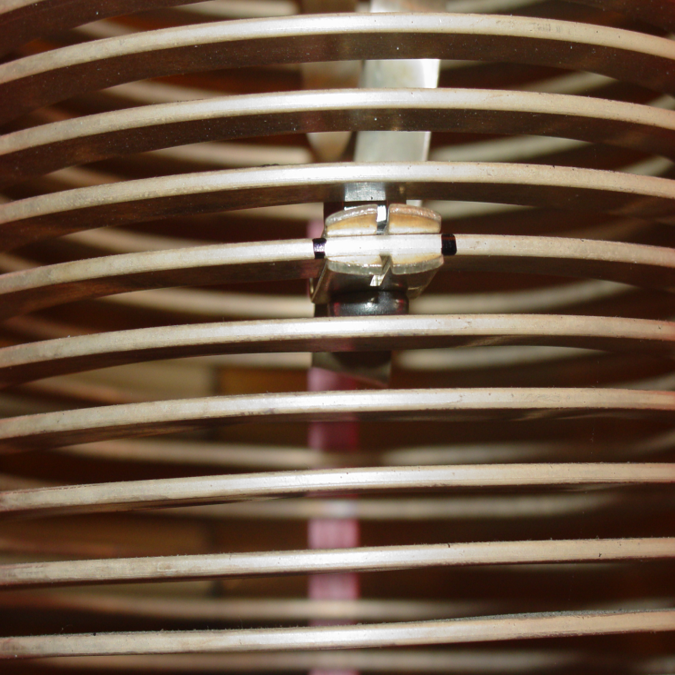

Cleaning continues with a spray bottle of 99% isopropyl alcohol and a box of rags. These can be picked up at a hardware or big box store. Clean the insulators, capacitors and other components and hardware.

The combination of humidity, dirt and lightning can cause a carbon track to form across a component or porcelain insulator to ground; so keep them sparkling clean.

As you work, check coil clips and copper tubing or strap connections to the various components for tightness. Where coil clips attach to coils, you may want to mark the connection with a Sharpie or other brand permanent marker.

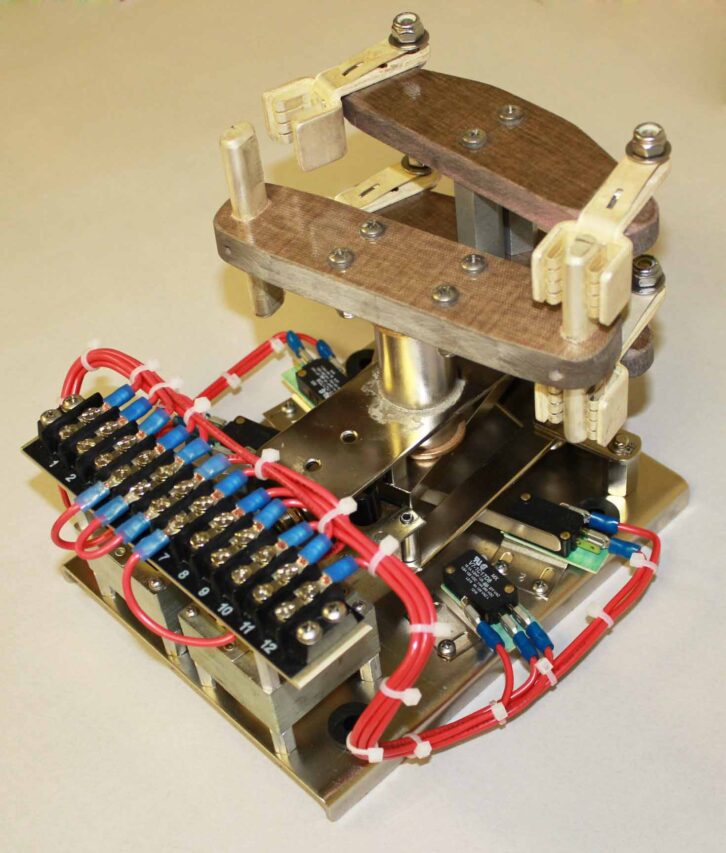

If an RF contactor is present, inspect the finger stock for signs of failure or overheating. Manually move the contactor armature, checking for easy movement and proper pivot bar contact seating into the finger stock sockets.

If the movement is not smooth, you may need to lubricate the mechanical linkage controlling the pivot bar. Use lube sparingly and apply it only to the mechanical linkage, not to the solenoids. Don’t forget to leave the armature in the correct position after exercising!

If your ATU is in a building and you discover peeling paint or efflorescence (crusty white mineral salts that can leach from concrete, brick or mortar), use a wire brush or putty knife to scrape the surface clean. If this is a problem at your site, perhaps start with this task so you don’t have to vacuum twice!

Next, clean both the inside and outside of the “bowl” insulator, and inspect the tubing that passes through this insulator to the tower. David uses Simple Green All-Purpose Cleaner, available from Amazon and the big box stores. It cuts through the dirt.

Follow that cleaning with a rinse and wipe with the isopropyl alcohol.

Throughout this process, take plenty of pictures to share with the staff and GM — especially if you encounter bee nests, snake skins or other interesting finds. These pictures help you promote yourself and your department — reinforcing that you aren’t going to the transmitter site for a nap!

Workbench submissions are encouraged and qualify for SBE recertification credit. Send to [email protected].