Technology Turnaround

Oct 1, 2007 12:00 PM, By Gary Wachter

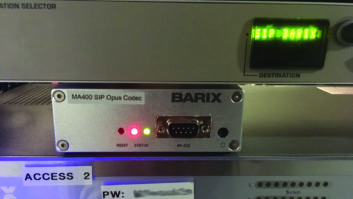

Support truss work for LCD monitors and speakers. Perfectly suited to attach T.V. lights.

Before last year, the venerable KKDA-FM (K104) control room was way past its prime. The studio was built in an era before remotes were carried via satellite and ISDN, and Tom Joyner created his morning show there and jetted to Chicago for the afternoon drive. Still embedded in the old cabinetry, were the boxes filled with sand to dampen vibration to the turntables. Vinyl records gave way to tape carts, which were replaced by CDs. And just a few years ago, computer playback replaced both.

What was remarkable is that this on-air studio survived all of the sweeping changes in technology and still sounded reasonably good. But the accommodations were well worn. Equipment that was not even imagined in the 1980s had to find a home in locations that were less than ideal. The flow of on-air talent was obstructed by the layout. People were cramped and scattered. Space was not used efficiently. It was a place you had to struggle to make work leaving little opportunity to be creative and entertain.

The time had come to abandon the classic U-shaped cabinetry and start completely from scratch. The challenge was that the new studio had to be in the same location as the previous, which could not be enlarged. To utilize the space to the fullest, some of the major specifications were:

- The space has to be adaptable to many varied scenarios without any physical reconfiguration. (From one person to the full morning show with operator, producer and guests.)

- All on-air participants had to see each other without looking around obstacles.

- Include a permanent home for keyboards, mice and controllers with easy access.

- Provide space for seated/standing visitors and live performers.

- Address acoustic considerations.

- Must have a unique look and feel.

Control room design

The existing room dimensions were measured, including windows, doors, HVAC, electrical and cable access points. A two-dimensional plan of the available area was drawn to scale using Microsoft Visio. Multiple copies of the layout were printed and then the fun began by sketching possibilities. It became apparent that a very unconventional solution was called for.

A paper model of the studio was constructed to prove feasibility of design.

On-air talent has unobstructed views. This arrangement provides for plenty of space in the left side of the room for guests and performers to stand or sit. Behind the console was room for one or two people side by side. The on-air guests are seated in front of the console in a 180-degree arc.

LCD displays are everywhere. What is the ideal location? It is accepted (and sometimes necessary) to have a monitor right in your face. You can still see the other people, sort of, from the nose on up, but communication is impeded and everyone starts looking like a �Kilroy was here� doodle. The solution turned out to be very simple: Stack the displays vertically on each side of the console, one directly at eye level, one just below and one just above.

To accomplish this, a lightweight stage lighting truss spanning from floor to roof joist was placed on each side of the console. A slightly arched horizontal section bridged the two trusses just below the 2’�2′ fiberglass grid ceiling. The truss structure gave the room a stylish flair and a practical place to mount the speakers, LCD monitors and other items. Visiting TV crews would also have a ready-made place to hang their lights.

This preliminary layout looked good on paper, but would it be practical and work in the real world? A three-dimensional drawing could be rendered, but it would still be viewed on a flat sheet of paper. What was desirable was a true three-dimensional model.

The solution was found using S.A.D. (scissor-aided design). It’s not very high-tech, but easily accomplished. All that was required was a copy paper box lid, two colored file folders, five wood stick cotton swabs (surplus from the tape head cleaning era), paper glue and a marker. I proceeded cutting out and gluing together a scale model based on the drawing. Within a few hours, a very effective mock-up of the new studio emerged. Little did I realize, experience from making dioramas in junior high school would actually have a purpose in the real world. While being able to view this model from all angles, the on-air crew was able to better visualize working in the new studio and provide feedback for the final design. When the planning was complete, it was time to find a custom furniture builder and begin actual fabrication.

Technology Turnaround

Oct 1, 2007 12:00 PM, By Gary Wachter

Cabinet construction

Inspiration sometimes strikes when you least expect it. While waiting for a flight out of Las Vegas McCarran Airport, the ticket and gate counters caught my attention. They looked appealing, solid, stainless steel with resin tops and accents. This high-tech look was similar to what I was searching for. If those fixtures could stand up to the daily rigors thousands of passengers can throw at them, they had a good chance of surviving in a radio station environment.

McCarran staff referred me to Bill Shiver, president of Volume Millwork in Houston. The company name is indicative of what the company does: construction of large quantities of cabinetry and fixtures. Most of the manufactured goods are custom ordered by the airline industry all over the country. Although not the customary assignment, Shiver was willing to build a one-of-a-kind for us.

Clamps hold seams tight while the solvent cures.

Shortly thereafter I was working with the company’s design engineer on the unique needs of broadcast furniture and provided him with drawing dimensions and photos of the S.A.D. model. CAD layouts were generated for approval. The final version would be sent to the shop’s computerized cutters. The cabinets would be constructed from plywood and finished with stainless steel. A horizontal weave pattern was embossed into the steel, which provided an interesting finish, hid scratches and provided a background for accent lighting.

Hiding scratches and wear was also a consideration in the selection of color and internal texture of the resin countertops. The Luxite countertops were also built from scratch. Resin was mixed with the chosen finish and poured into forms and allowed to cure before finishing. The main countertop surface was such a large area, it had to be built in four pieces and assembled into one solid piece on site.

The truss could have been custom built as well, but I found the perfect size and weight with the Quick Truss from Milos Structural System. The factory built and welded the sections to my specifications and shipped them to Houston for assembly. The sections connect with barrel connectors held in place by retaining pins.

Attaching to the structure was easy with the Milos Cell clamp. It attaches around the vertical pipe and is secured with a wing nut. It has a �” mounting hole on a flat surface. This has been perfect for mounting everything, including the two-piece Victory LCD mounts. Pressing a release clip and lifting up and away can easily remove the display.

Dedicated displays

With all of the computer displays in the contemporary control room, it is easy to become overwhelmed by a dedicated screen for every source. Some monitors needed to been seen all the time, others just on occasion and do not justify a dedicated display. This would significantly cut down on the clutter.

The three monitors to the right of the console are fixed: Media Touch on-air playback on the bottom, Vox Pro in the middle and VRC transmitter remote control on top. The monitor on the left is switchable (using keyboards shortcuts) and has all of the primary sources plus backup on-air playback, call screener, liners and Internet access. On the opposite side of this truss is another monitor with independent switching for the talent/host position. An Adder eight-input, two-output keyboard, video, mouse (KVM) switcher was utilized. If the same computer is selected at the same time by both positions, control is automatically determined by which keyboard or mouse is in use. Located in the center support pedestal is the switcher, KVM extenders and VGHA distribution amplifiers.

Technology Turnaround

Oct 1, 2007 12:00 PM, By Gary Wachter

Host and guest positions

Guests are seated on tall stools (or stand) around the table extension behind the console. Two people can be accommodated on each side. A 6″ high center riser section in the middle of the counter supports six Mika microphone arms. The Mika arms are very streamlined and reduce the visual clutter.

A touch screen with headphone source selector serves positions on each side. Accent lights also illuminate the countertop, filling in shadows from overhead lighting.

Located in the center of the microphone nest is an omni-directional Mirage Nanosat speaker for the phone caller audio. The unique Nanosat has a 2 �” woofer pointed up, which is dispersed by a cone containing the tweeter. The near uniform dispersion allows everyone to hear the caller equally well. The mounting location is ideal � at the minimal sensitivity point of the Shure SM-7B microphone pattern.

A separate Benchmark Audio amplifier with volume control and �” and ?” jacks mounted on a stainless steel plate in front of each person provides headphone monitoring. The panel can be unscrewed from the riser and the entire assembly unplugged for maintenance when needed.

The audio for the headphones is chosen by either a source selected on the console or 7″ LCD touch screen placed between each set of headphone positions. A small computer in the pedestal running Logitek’s Vscreen software drives the panel. Vscreen allows complete flexibility in designing an interface used for selecting the monitor source, turning on/off the microphones (with virtual buttons), timer and VU metering. This can be easily changed in the future to meet any need without having to rewire anything, just add the software code.

Under the right side countertop is a rack opening that holds the control surface power supply and a rack panel with jacks to bring external sources in and out. This is where the TV crews would plug in to get a program feed. Just about all levels and formats are provided, so external adapters are not needed, including AES-3, balanced line, mic and -10 consumer-level on RCA jacks. The sources are selected on the control surface and can provide just one microphone or the entire program.

Removing the blank rack panel above reveals another small rack with the CAT-5 patch panels, surge suppressors and network switches. Twenty-four separate CAT runs are made to a matching panel in the technical area. At each end, the runs are first looped through APC rack-mounted surge suppressor modules before going to their destinations.

Running KVM data through CAT-5 is a lifesaver, but on long runs the video can become blurry from the individual red, blue and green colors arriving at different times. This skew is because each pair of rated CAT-5 cables has different twists per inch that are used to control timing and reduce data collisions. Some high-end KVM extenders can compensate for this, and in many cases the length may not be a significant problem. But if it is, KVM-type cable is available with all the pairs having the same twists per inch. Be careful, this cable cannot ever be used for networking. To get the best of both worlds, Belden has introduced Video Twist 7988 cable with minimal skew, used for either application.

The lower cabinets on the right have two roll-up doors. One is storage for the DJ mixer and turntables, the other provides access to several computers located in the studio. The entire cabinet is cooled and a positive pressure is maintained by taking a 4″ tap from the main air conditioning.

The upper cabinets contain four 8RU openings for the commonly used CD recorder, players, EAS, light controller and other equipment. In the center space is a 1RU power strip to provide convenient access to ac for DJ mixers, chargers and other equipment temporarily brought in.

p>At the very back are remote control buttons for the Broadcast Tools Program Switcher. This is an independent controller that will allow the operator to bypass the control room entirely and place another source on the air directly. To be used in an emergency or maintenance, selections include control room, on-air playback computer, production room or router. The buttons are large, require a deliberate press and have a circular guard to prevent accidental triggering.

Special lighting

The keyboards and a controller have a permanent home on a fixed shelf.

Shadows from the riser and the cabinets were substantially reduced by placing white LED rope lighting in a groove under the lip of the countertops. This also illuminated the keyboard shelf very nicely. The idea was also to provide accent lighting that would reflect from the patterned stainless steel.

The original thought was to use RGB rope light where each of the primary colors could be varied to produce a wide range of colors. A 10′ piece was purchased to experiment with. The rope was actually a rectangular flexible strip that could be mounted underneath the counter lip, but it could not accommodate the sharp bends. It did not go to waste, as it was positioned in the upper horizontal truss segment pointed at the ceiling, creating a light show for the entire room.

The wing to the left is general-purpose counter space with plenty of room to place briefcases or spread out papers. When cleaning up, trash can go directly down a chute in the center to a removable trashcan inside the support column.

Technology Turnaround

Oct 1, 2007 12:00 PM, By Gary Wachter

Console

The Logitek audio engine and Mosaic Control Surface running Supervisor software simplified many common repetitive tasks. Software triggers were written to accomplish a variety of tasks.

Running a show with a full house of guests requires turning all microphones on and off. This has been reduced to a single press by simply turning the main mic on or off. The unused talkback button on each mic channel has been repurposed to a group take. A mic with this take button enabled will follow the main mic.

Another very useful feature is the one-button record. When pressed, it sets up the phone mix minus, assigns the microphones, switches the headphone monitoring, mutes the speaker, starts Vox Pro recording and illuminates the Beta Brite with a big red recording message. When the button is pressed again, it reverses the process and restores the monitoring to its previous setting.

A channel was made under the counter lips to accommodate the LED rope lighting.

The LED Beta Brite panel in the front of the studio displays status messages. EAS alerts, hot mics, off-air and even high/low audio levels get a pointed out. It is not overused; otherwise it would be more prone to being ignored.

The LCD big screen monitor is capable of not only showing TV, but can also display computer screens from the KVM switcher. It makes the screened calls and liners easy for all to see.

The K104 Web cam provides a peek inside the workings of the radio station. From its perch inside the truss, it presents a great bird’s eye view of all the action in the studio.

The pre-planning and attention to details paid off big in the end. The long anticipated new studio worked better than expected. It is a very exciting, vibrant setting to create inspiring entertainment.

Wachter is director of engineering of Service Broadcasting Company, Dallas.

Equipment list

- Acoustics First Sonora Panels

- Adaptive Displays Beta Brite

- Adder Adder Link IP

- Adder Smartview 2xPro8

- Alesis DSP820

- American Lighting RGB & White Rope

- APC Modular rack mount

- Audion Labs Vox Pro 4.1

- Audio Science ASI5044

- Belden wire and cable

- Benchmark HPA-2

- Broadcast Tools DAS 8.4

- DCS DCS 995

- Dell Optiplex

- Fostex RM-2

- HHB Burn-It Plus

- IO Gear GVS-94

- Lilliput 7″ Touch HR702

- Logitek Audio Engine

- Logitek Mosaic

- Lucid Clk-x6

- MediaTouch Onair 2.6

- Milos Structural Systems Quick Truss M222

- Mirage Nanosat

- Network Technolgies KVM-300

- Samsung 940N

- Shure SM-58

- Symetrix Airtools 6100

- Symetrix Airtools 6200

- Tascam CD-01UPro

- Telos NX-12

- Victory Mounts XUF-1330

- Volume Millwork studio furniture

- Yellowtec Mika