Last Week’s Question

Last time we posed the following question for CBRE-level exam takers: “How are transmitter final stage efficiency factors determined?” The choices were:

a. Directly from the transmitter’s reflectometer.

b. From manufacturer’s supplied data and/or from measurements taken by a calibrated power measuring device rationalized against input power to the final stage.

c. By multiplying the final stage current, applied voltage and a “K” factor of 40 percent subtracting the drive power.

d. From the nameplate ratings.

e. From the final device manufacturers’ spec sheet.

SBE certification is the emblem of professionalism in broadcast engineering. To help you get in the certification exam frame of mind, Radio World Engineering Extra poses a typical question in every edition. Although similar in style and content to exam questions, these are not from past exams nor will they be on any future exams in this exact form.

The correct answer is B.

Final stage efficiency values are most often used in “indirect output power determinations” to validate that the transmitter is producing the correct power output to achieve the licensed radiated power.

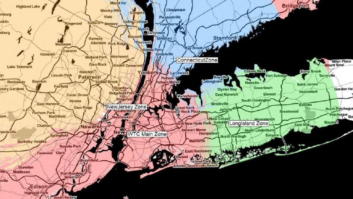

Fig. 1: Efficiency chart for a solid-state AM transmitter identifying the voltage and current combination (colored region) where the output will be legal (between 90 and 105 percent TPO) and where a constant efficiency factor is present. The FCC’s rules at 47 CFR73.267(c) (for FM) allow that output power to be calculated by multiplying the power consumed in the final stage by an efficiency factor, either supplied by the manufacturer or originally determined by using a calibrated power measuring device.

The power efficiency factor from the manufacturer usually is provided in the original copies of the instruction book and sometimes is an actual measurement for a specific serial number transmitter at the licensed TPO. Occasionally these factors are annotated as graphs, as the efficiency can change somewhat with drive and power level across the legal FM power range of 90 to 105 percent TPO.

Fig. 2: Final stage efficiency chart from a classic 10 kW RCA FM transmitter with a 4CX10000D output tube. Notice that the efficiency is not quite a linear function for varying power levels. If you are using the indirect measurement system for TPO, the source and validity of that number have to be available to the FCC if and when it inspects your station, and should be a permanent part of your station’s engineering records. On a more day-to-day level, these numbers are invaluable for troubleshooting transmitter final problems and a validation that tuning, loading, etc., are still at nominal and correct.

The efficiency factor also can be determined on site by using either a calibrated thermo-couple or calorimeter power meters.

Fig. 3: Water-cooled dummy load that can be used in caloric power measurements. Notice the fluid in/out fittings at the bottom, and Benjamin the Cat checking out the 6 inch coax input at the top. This unit, the author’s personal high power load, is capable of handling an 80 kW input. In the new universe of digital radio, and especially for HD, the typical peak-reading watt meter (such as the classic, diode sampling through-line type) produces indications that are not fully indicative of the real power in the envelope. Peak-reading meters are only fully accurate with a near-constant CW envelope such as an FM carrier, and do not properly report the varying digital sidebands of HDFM.

In a thermocouple power meter, selected dissimilar metals will produce a current flow at their junction when heated. The increased level of this current flow is proportionate to the heat induced. A thermocouple in a dummy load resistor of characteristic impedance that matches the output of the transmitter can provide us an accurate measurement of power produced on a repeatable basis.

A simplification of the design can be achieved by merely sampling the RF current flow through a “current resistor” in line with the load, which is the standard concept for an AM base current meter.

The calorimeter power meter transfers the heat from a dummy load into a cooling liquid that flows around the resistor. For maximum accuracy, the cooling liquid needs to be inert and have no dielectric properties like distilled water or certain oils and anti-freeze mixtures. The flow rate of the cooling fluid, the specific heat of the fluid and the change in the temperature of that fluid between input and output ports are factors in the final calculation, yielding an exceptional degree of accuracy especially in high-power measurements.

Here are your questions for the next issue: “What is a dB? What is a Neper? Whom is the dB named after?”

C.S. Fitch, P.E., CPBE, AMD, is a frequent contributor to Radio World.