(click thumbnail)Morning host Ken Lass at the Wheatstone G6 Control Surface in WDJC’s control room. ‘The studios are in a line, with windows between, so that you can see through the receptionist’s area and into the WXJC control room,’ said Poole.Studio consolidation projects rarely go off without a hitch, but the curveball thrown to Crawford Broadcasting’s Stephen Poole was a whopper.

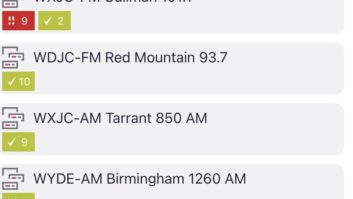

As market chief engineer for the company’s Birmingham, Ala., operations, Poole had planned the move of WDJC(FM), WYDE(FM), WXJC(FM), WXJC(AM) and WYDE(AM) into a gutted 10,000-square-foot space for more than a year.

The plan called for eight control rooms: five for the existing stations and three for HD-2 expansion in the future. Then things started to go south.

At the last minute it was discovered that local codes required a space of this size to have a sprinkler/fire-suppression system. This instantly put the project over budget; and problems retrofitting sprinklers into an older building delayed construction well into November. Instead of having a month to make the move, Poole was left with a weekend. He called for backup.

(click thumbnail)A view looking the other way, from the WXJC control room through the talk studio, then reception and into the WDJC control room. WXJC does most of Crawford’s talk programming.In addition to Poole’s assistants Todd Dixon and Jimmy Parker, corporate chief Cris Alexander sent staffers Ed Dulaney from Denver and Rick Sewell from St. Louis, as well as Robert Payne, a contractor from Dallas, to lend a hand.

Wheatstone was the major equipment supplier, providing five Generation 6 control surfaces, six Bridge Routers and studio furniture for nine rooms.

Work on the project began with assembling studio furniture. To keep costs down, Poole had opted for Wheatstone’s TechLine furniture, and found the results gratifying. “The studio cabinetry was ‘value’ in name only,” he said. “It was a breeze to put together and looked beautiful. Wheatstone pre-cut it for our equipment; all we had to do was drop it in and go.”

The simplified wiring needed to interconnect control surfaces to routers saved time and provided a bonus. “With the Generation 6/Bridge Router system, any source can be made to appear on any control surface in the building: punch once, use everywhere,” said Poole. “I didn’t think this would be that useful before I tried it, but now, we can’t live without it.”

More time was saved when a Wheatstone rep reprogrammed the console default assignments and e-mailed them to Poole so they would be ready to go on Monday morning.

(click thumbnail)Auxiliary studios (still a work in progress), looking from the #2 talk studio, through Control 2 and Control 1, and into talk studio #1.

Crawford Birmingham uses the RCS/Prophet NexGen automation; its flexibility helped with the move, as Poole explained: “NexGen has so many options to stay on the air. For example, control room computers can be put in ‘local database mode’ and operate stand-alone for up to two days. While we were juggling STLs and moving the audio servers to the new building, we put the PCs at the old studios in this mode to stay on the air.”

Poole also had to move five STLs: two T1 lines and three microwaves. Through careful juggling of signals onto standby STLs, he was able to get the gear moved without a loss of airtime.

For AC backup, Crawford installed a 45 kW generator, sufficient to keep each studio live in the event of a power failure. They also placed three 2200 watt, and five 1500 watt APC UPS units into service to hold things together until the generator comes on line.

Through a Herculean effort by Poole and his team, the five-station move was completed over a weekend. All that remained was the celebration.

An evening of ribs at Dreamland Barbecue allowed the group to savor their accomplishments.