Everyone has his or her own tools and toolbox for the radio broadcast engineering job. My favorite for more than 30 years has been a toolkit like one used by telephone repairmen in years gone by.

The kit is not fancy, it just works. I have worn out three in that time and am glad they are still available because I may need another by the time I go to repair that big transmitter in the sky.

Imagine that: wearing out a tool kit! Well, when you use the kit every day, it makes sense.

Durable

The one I have is a C.H. Ellis Telecom Tool Case with high-density polyethylene construction and a padded handle (because it weighs in at 25 pounds with my tools inside). This kit is 12 x 16 x 5.5 inches.

If you want one, look for part number 26-4509. It is $176 and usually on sale for less at www.alltimetools.com.

In the big scheme of things, it doesn’t matter what the tools and case cost; what matters is that they work for the situation.

This kit does not come with tools. I put in what is needed and leave out the rest. To me, a toolkit is not a large box with tools rattling around inside; it is itself a tool to get the job done.

(click thumbnail)

What I get with this toolbox is organization. It has a hinged pallet that stores tools and separates the bottom of the kit from the top where pouches are. When I go to leave a job site, I will spot what tool is missing just by glancing at the kit. There will be an open pocket where a tool belongs.

What’s in the kit? The answer is, not everything, just enough to do 90 percent of the work. The rest of the tools are in the service van (see “He’s the Man in the Van” in the Dec. 1, 2010 issue).

I’ve stocked the top cover with two 6-inch adjustable wrenches, a paint brush for cleaning, one or two cigarette lighters for heat-shrinking tubing, solder, right-angle ratchet screwdrivers, a 4-inch adjustable wrench for tight spaces, contact burnishing tools, Q-tips, wire cutters and long nose pliers.

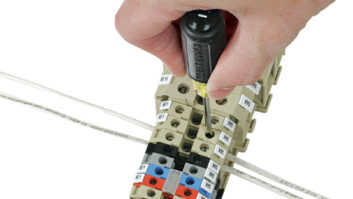

The hinged divider has two universal screwdrivers, because inevitably someone wants to help me but has no tools. Also here are incandescent and LED flashlights, a torpedo level so my work can look straight and level with the rest of the world, slip-joint pliers, jeweler’s screwdrivers, tie wraps, marker tie wraps and clip leads.

The bottom of the kit contains an Xcelite ratchet crimping tool, a box of assorted fuses, a mirror, a tone generator for tracing audio lines and a beat-up old Beckman digital multi-meter.

The meter looks terrible and clients sometime eye it skeptically; but that is all I need to diagnose a problem 95 percent of the time. (A much larger RMS reading meter resides in the van.) The bottom also contains Caig Labs DeoxIT contact cleaner, solder wick and magic glue.

Clean and restock

The soldering iron is interesting because it has a 12-foot power cord. Actually, it is a cord that I spliced onto the end of the existing 4-foot soldering iron cord, which always seemed too short (don’t tell UL about this).

A copper tube makes it possible for me to put the soldering iron back in the kit while it is still hot. One client joked that I can use it to make a quick getaway. I joked back, reminding him that my work carries a “tail-light warranty” — the warranty is good as long as he can see my van tail lights.

(click thumbnail)

Also in the bottom of the kit are a box of hex wrenches; assorted crimp terminals; resistors categorized by size; wire nuts; silicone heat-transfer grease; and rack hardware. Also: electrical tape, a punch-down tool, a tape measure, utility knife, stubby screwdrivers and a few feet of wire. This last item always seems to come in handy for incidental wiring.

Xcelite has some fine tools that I love. The socket set with roll-up pack gets constant use. The yellow-handled Xcelite R184 screwdriver is long, thin and amazingly strong. Its little green cousin, the R3324, is good too.

Maintenance: Once a month I go through the bottom of the toolkit to clean out dirt and to restock the crimp terminal stock.

The tools change as requirements for installation and service evolve. What kind of a special widget will be required in the toolbox for the next industry innovation?

The author wrote in December about using a van for radio engineering work. For more good ideas, visit radioworld.com and click on the Tech Tips tab under News & Technology.

Mark Persons, W0MH, is a Certified Professional Broadcast Engineer and has more than 30 years experience. His website is www.mwpersons.com.