KQED San Francisco’s CE Larry Wood and I were chatting about engineering experiences that rarely see the light of day. Larry knows many engineers who have been through much tougher experiences than he.

As broadcast engineers, we are expected to deal smoothly with the many types of problems that happen daily. Nonetheless, some problems are special, rare enough that trying to solve them can be considered going above and beyond the call of duty.

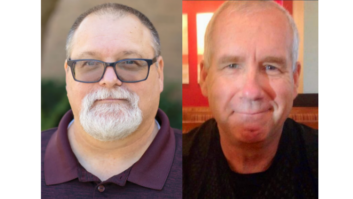

Check out this actual merit badge from the Boy Scouts. Above, Life Scouts Michael Cobb and Konnor Sanders, from Troop 597 in Dacula, Ga., show off their radio badges.

Getting recognition for these “extreme” job experiences is difficult. Sometimes our bosses may say “well done.” Larry has even received a bonus once or twice in his career. A few times, he has been recognized in staff meetings too, which is nice. Often, the broadcast engineer gets no credit at all; worse, you’re made to feel like this is just part of your job.

Such “special efforts” don’t fit easily on a résumé or CV. Larry is certified by the SBE, but there’s no part of his CPBE certification indicating the many extra broadcast “life experiences” he has been through.

With tongue in cheek, Larry proposes we create the broadcast engineering equivalent of Boy Scout merit badges. They could be called EEBs or Extreme Engineering Badges. Larry has even given thought about what would be necessary to earn one, and offers a few suggestions.

He has experienced all of the EBBs below. What are yours? I’d like to hear.

• Plate transformer insulated from ground by sitting on 2x4s due to short in the windings

• Replace/repair a stolen AM ground system

• Endure a full FCC inspection

• Experience a tower falling

• Getting back on the air and rebuilding after a fire at the studio or transmitter site

• Dealing with an automation system main storage crash

• Replace a large coax switch by yourself

• Driving through extreme storms to get to a transmitter site, or to refuel the generator

• Dealing with roof leaks at the transmitter site

• Getting shocked while cutting Belden 8451 that someone wired to 120 VAC

• Operating a three-phase transmitter on two phases by giving the blower a spin to get it turning

Maybe we should also grant a badge for extreme remotes … like from Hawaii using Switched 56, in the days before ISDN, the equipment showed up late, and with smoke coming from the wet telco wiring after the remote started. Or how about the popular “installation of a new transmitter,” where you move the equipment and do the AC wiring, HVAC, control and RF plumbing all by yourself, with no bonus or overtime?

Drop me a line with your suggestion of how to earn the RW Extreme Engineering Badge (and what it should look like). Email to [email protected].

Larry Wood also sent in a couple of suggestions for engineers who plan new rack rooms.

First, keep in mind that as we transition more and more toward everything Ethernet, many servers are deeper than the standard equipment rack. Check with your automation equipment provider as to the rack dimensions of its servers. Consider investing in deep racks so there’s no problem closing the rear door or pinching cables coming out of the rear of equipment.

Fig. 1: Building a rack room? Consider using rack dividers with removable covers.Fig. 2: The divider provides plenty of space to route cables.Fig. 3: Wiring can be routed neatly through the chase created by the rack divider.

In addition to the deep racks, in Larry’s rack room, he specified racks with vertical rack dividers, seen in Fig. 1. This option separates the two racks with a removable divider cover. As you can see, the divider covers are latched, but can be removed easily to gain access to cable runs between the racks and going down into the raised floor. Fig. 2 shows the space between the racks, with the cover removed. In Fig. 3, you can see how neat the wiring can be having this space between the two racks to run wires and cables.

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send tips to [email protected]. Fax to (603) 472-4944.

Author John Bisset has spent 46 years in the broadcasting industry and is still learning. He handles West Coast sales for the Telos Alliance. He is SBE certified and is a past recipient of the SBE’s Educator of the Year Award.