It’s no secret that I love all things aviation. There’s nothing better in my view than slipping the surly bonds of earth and launching into an azure sky of still, smooth air and watching the Earth move beneath my wings.

It should be no surprise, then, that I subscribe to a stack of aviation magazines.

In AOPA Pilot a few months ago, columnist Natalie Bingham Hoover, writing about diagnosing and solving problems with general aviation aircraft, hit upon a principle that has great application in broadcast engineering.

The writer asked her aircraft mechanic the secret to his ability to diagnose and isolate aircraft problems so quickly.

[Subscribe to Radio World Engineering Extra]

His response: “It’s simple. Always start with the easiest solution. And if you still can’t figure it out, then go from the known to the unknown.”

Those words just about jumped off the page at me. They describe, in a nutshell, the process I have used for 40+ years in troubleshooting broadcast systems and equipment. Before I’d read that, if asked I would have been hard pressed to describe it so succinctly.

Train Wreck

Years ago, we had a young resident engineer living at the transmitter site of our Los Angeles radio station, which was a three-tower 10 kW directional AM.

This young man had a good head on his shoulders but he didn’t have a lot of directional AM experience … okay, he didn’t have any. But he was willing to live alone at a transmitter site on an island off the California coast and keep an eye on things.

One day he called me and said that the whole directional pattern was screwed up. None of the parameters were anywhere close to correct. It was a train wreck. I could hear the near-panic in his voice as he conveyed the situation to me.

I didn’t know that array well at the time. It was a 1952-vintage system and used a tank-type power divider with jeep coils, something I had no direct experience with. But in an effort to calm the new engineer down, I started asking some questions:

Is the station on the air?

Yes, it’s on.

What is the common point current?

It’s normal.

How is the transmitter behaving? What are the meters telling you?

It looks about like it always does.

With that short exchange, I began to get a picture of an array that seemed to be operating normally despite the antenna monitor indications.

I suspected a sample system problem, and because it was affecting the indicated parameters for all the towers, I thought that the problem might be in the sample for the reference tower.

To confirm this, I sent the engineer out with the field intensity meter to look at all the monitor points, not an easy task on that island. This job was a half-day affair with a lot of off-roading to interesting locations.

A few hours later, he called: monitor points normal.

That sealed it. The array was fine. We were dealing with a sample issue.

I grabbed some test equipment, caught a flight out to L.A., took a helicopter to the island and within a very short time had found the issue: a shorted (or mostly shorted) sample line to the reference tower.

Fixing the problem took a lot longer than finding it and involved a lot of digging. But we did find the buried lines, identified the one with the problem and spliced in a new piece, replacing a 3-foot section that had gotten waterlogged. After that, all was well on the monitor.

When something like that happens, we tend to think the worst, and sometimes it is the worst. But we have to discipline ourselves not to jump to that conclusion.

We have to start with the easiest solution and work our way through to the harder stuff. We must eliminate the things we most easily can first and go from there. And whether or not a particular troubleshooting step identifies the issue, it is not wasted. With each step we remove one variable from the equation.

If, on the other hand, we jump to an unsupported conclusion and start turning knobs, we add a whole bunch of new variables … unless, of course, we get lucky and somehow manage to hit on the cause of the problem by accident. Hey, it happens.

Known to Unknown

But suppose that we have eliminated all the easy stuff and still haven’t isolated the problem. What then?

That’s where the “known to unknown” process comes into play.

If you can find a similar part, device or circuit that is working correctly and compare it to the one that’s not, you may well be able to figure out the problem.

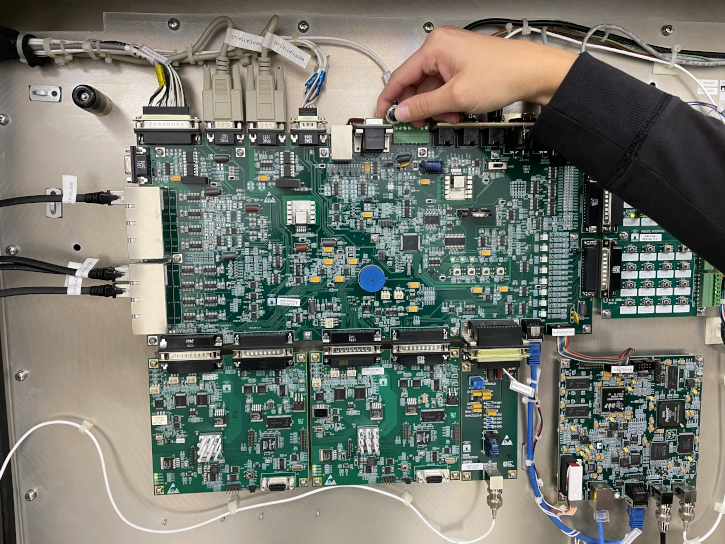

It may be a matter of subbing in a known good part or board to see if that makes a difference. In the case of the directional array problem, it was a matter of comparing the TDR display of a known good sample line to that of the suspect line.

If it’s not possible to compare or substitute components or assemblies, another option is to compare voltages, currents, waveforms or impedances to known good values or examples.

In days gone by, manufacturers would often note such known good values on the schematic or in notes. Experienced engineers, after completing a project, often record such values in a notebook, a log or even a note affixed to the end of a transmission line. Those benchmarks can help isolate a problem.

The point is that jumping to unsupported conclusions or performing troubleshooting steps out of order is a waste of time, effort and a psychological drain.

Going back to the aviation mag column, the writer concluded by saying that “with our airplanes, like so many things in life, the first step in solving a problem is simply believing we are capable. After that, a little common sense helps. And … remember that the right solution is often the simplest one.”

That has certainly been my experience over the years.

The author is director of engineering for Crawford Broadcasting and technical editor of Radio World Engineering Extra.