Fig. 1: Straw, grass, and nesting materials don’t mix with a 50 kW ATU. Our past few issues have generated some interesting responses from our readers. Let’s start with an observation from contract and projects engineer Ed Dulaney. After reading Mike Vanhooser’s tip about using concrete to protect copper strap (Workbench July 18), Ed said he had to shudder. He writes, “It’s a very bad idea to put a ground strap into anything so rigid as concrete.”

Ed explains that when lightning hits an electrical conductor, it induces a massive electromagnetic field. When this EMF travels along the conductor, it literally “vibrates” with the energy that is induced into it. Ed has seen photos of concrete pads that had copper rods in them, which were then struck by lightning. The damage is minimal and collateral damage is limited, as most of the pieces of concrete fall less than 10 feet from the point of entry. But the forces are evident.

However, imagine if the same thing happens to the base pier of a tower, where the strap is covered in concrete. A few fractures in the pier are all it would take for the tower to come tumbling down!

Ed says he’s all for covering copper straps in tar, paint or other pliable material. But he’d never put anything that has the possibility of carrying a million Joules of energy into a completely rigid environment.

Ed raises a valid point; but for the trenches in Mike’s case, the strap was laying in the trench, covered with dirt, and the concrete was used as a cap to discourage digging. Amazing the schemes we have to come up with to save our copper!

***

Marc Mann provides an interesting comment, after reading Greg Richwine’s clean-up of beryllium contact shavings (Workbench Aug. 1). To prevent the spread of the shavings and dust, Greg carefully wiped up the residue that lay under the contactor. His caution was warranted, as beryllium is a known carcinogen. Marc wanted to bounce Greg’s procedure off a friend who is a retired industrial hygienist and OSHA inspector —but don’t hold that against him, Marc adds.

More important, the OSHA inspector mentioned something that Marc hadn’t considered: There is a reasonable probability that during the erosion of the beryllium contacts, a micro aerosol of BeO (beryllium oxide) may have been generated. If the device had a cooling system, i.e., a fan or blower, and the effluent (heat and BeO aerosol) was not vented to the exterior atmosphere, the room containing the transmitter may well be contaminated and an air test would be prudent.

Now in Greg’s case, this was not a transmitter, but a phasor cabinet – which I guess could have a blower associated with it but more than likely, does not. However, the hazard still remains and should be considered by engineers doing maintenance.

Anyone in a similar situation should stay aware of this and notify any employees who frequent the area of this potential health hazard. Marc realized some readers think OSHA requirements are too strict at times; however, beryllium is nasty stuff and should be treated with the same respect as when transformers with PCBs need remediation.

How much is too much, according to OSHA?

Fig. 2: Check the tower base spark gap, making sure the balls are smooth. The amount or length of exposure to beryllium necessary to cause a specific individual to develop CBD is not known, but recent information suggests that even short exposures to levels of beryllium below OSHA’s Permissible Exposure Limit (PEL) of 2 µg/m3 averaged over an 8-hour day may lead to CBD in some workers.

Our Radio World Links page (radioworld.com/links) has a link to an OSHA safety bulletin that readers may find useful. Simply Googling “Beryllium contact hazard” will provide even more information. Thanks to Marc Mann for his thoughts.

***

No beryllium evident in Fig. 1; just a lot of rubbish, mostly collected by rodents. This abandoned 50 kW site is soon to be back on the air, but only after some extensive cleaning and maintenance. Be sure to use a facemask when removing the rodent droppings and nesting materials from inside ATUs. Tighten the connections, and ensure things like the spark gap on the tower (Fig. 2) is properly set.

Note the gouge on the bottom ball. To guard against sustained arcing across the gap, use crocus cloth to smooth out any pitting caused by lightning strikes. Thanks to Sim Mangga of Malben Engineering for the pictures.

Contribute to Workbench! You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips to [email protected]. Fax to (603) 472-4944.

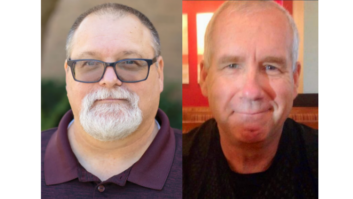

Author John Bisset has spent 43 years in the broadcasting industry, and is still learning! He is SBE certified, and is a past recipient of the SBE’s Educator of the Year Award. He recently joined Elenos USA, an FM transmitter company based in Miami.