John Lackness is sales coordinator at RadioGearheads, a company founded last year by Jim Offerdahl. But as a former chief engineer and the current owner of a couple of tractors, John also enjoys doing some mowing at Texas transmitter sites on the side.

(Mowing isn’t a job for a station’s full-time engineer, who has more important duties. You shouldn’t be washing the GM’s car, nor should you be mowing the lawn, unless you really want to. In John’s case, it is a paid side hustle, and there’s nothing wrong with earning a few extra bucks.)

Based on his experience, here are a few tips to share with your own mowing contractor as springtime approaches.

First make sure the contractor is insured. Then go out with your prospective mower and inspect the property. The key is to identify small problems before they escalate. Assume nothing.

Identify anything unusual — hidden hazards, including guy wires. John visited one site where the owner had installed small aviation hazard balls on the lower guys just to make sure they were visible to anyone working on the property.

Also ask the contractor to let you know about other issues they find during the work. John takes notes or snaps pictures with his phone and texts anomalies to his clients as he finds them.

Watch for ruts or sunken areas that might indicate the presence of burrowing animals. I remember a site where a woodchuck had discovered sand-filled trenches that had been dug for the transmission lines and control cables of an AM directional. Sand was easier to burrow through than dirt, and this den extended 60 feet.

This problem was discovered when a mowing contractor saw a woodchuck “disappearing” into its den, frightened by the noise of the tractor. Fortunately the animal had not yet munched on the cabling. The park authority provided a Havahart trap to relocate the varmint.

Finally, ask your mowing contractor about the equipment to be used. John has an open-air tractor that maneuvers well around anchor points and tower fences, as well as a second larger rig with an air-conditioned cab, ideal for Texas summers.

PS: The landscape contractor might value promotional airtime. Ask about a possible trade deal.

Timely reminder

While we’re on the subject of walking around your site: Be aware that winter freezes and thaws can take their toll on transmitter buildings. The accompanying photo shows what one engineer found on a recent site visit. Damage to fascia can lead to roof leaks.

Walk around the entire building, scrutinizing everything.

An end to juice jacking?

USB “data blocker” devices are available in every imaginable configuration. William Harrison, technology manager of WETA(FM) in Washington, D.C., recommends you keep at least one of these “juice jacking preventers” in your kit, just in case you need power from an untrusted source.

Simply attach the data blocker between your USB cable and the power source to provide a physical block to data transfer/syncing. The device deters hacking and viruses by disabling the data pins.

PortaPow invented the first data blocker in the U.K. back in 2013. They manufacture blockers for USB-A to -A, as well as USB-C and other configurations, like this one. Single units less than $7, and multi-packs are available.

Melt the goo

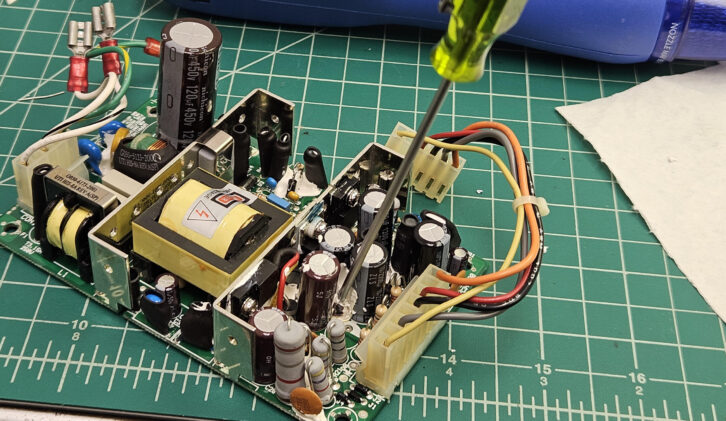

Planning to replace capacitors in a switched-mode power supply? Sinclair Norfolk Director of Engineering Dave Morgan sent along a great tip.

You probably will encounter a hardened adhesive goo that discourages component removal. Dave’s trick is to use a heat gun to heat the tip of a Greenie screwdriver, then immediately apply the tip of the hot screwdriver to the hardened goo. It will soften upon contact, making removal of the component possible. The Greenie pinpoints the heat so as not to damage other components, which might occur if you just directed the heat gun onto the assembly.

Attending NAB?

As you can read in the preview issue of Radio World, the NAB Show will be a busy one. If you are fortunate enough to attend the convention, please be sure to visit the companies that support Radio World with their advertising; they make it possible for us to bring you this column. You will find me in the Telos booth. It’s always good to meet longtime readers and exchange ideas!

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].