Kintronic Labs is known for its high-quality manufacturing. When the company sees a need, they create a solution.

This is how the LAB Series of dehydrators was developed. Eliminating the piston compressor and adding redundant features sets this series apart from other brands. Optional SNMP protocol remote control is also available.

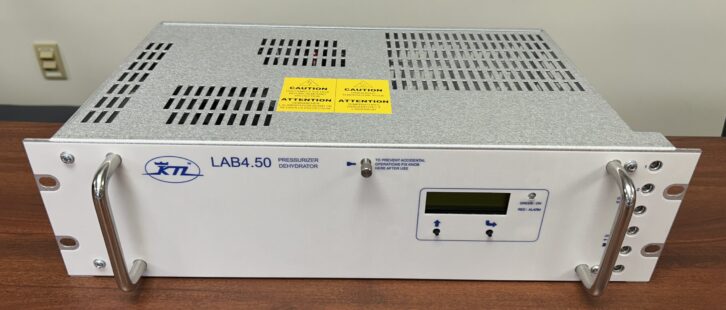

Shown here is the LAB4.50 model. Underneath the hood you can see that the dehydrator design consists of two alternating diaphragm pumps. While the first chamber is active, the desiccant in the second chamber is regenerated through heating. Both pumps are controlled electronically by pulse width modulation (PWM), which ensures a flow rate equivalent to the real-time leakage rate. The use of diaphragm pumps eliminates the loud noise associated with traditional piston-type dehydrators.

Kintronic also is known for thorough instruction manuals, and this product comes with a color pictorial document of internal wiring and hose connection; there’s no guessing here.

The company makes two models; the LAB4.50 is the smaller of the two and adequate for most broadcast facilities. If you’re putting up a new tower or transmission line, consider replacing the outdated dehydrator with this state-of-the-art model.

Impact engineering

A lot of readers could relate to Frank Hertel’s list of engineering “terms” that we shared at the end of a recent column. These are phrases you can use to impress your co-workers.

Archie Simpson particularly liked “The failure was corrected using percussive maintenance.” (Translation: “I hit it and it started working.”)

At Archie’s college station, they called it “impact engineering.”

He recalls that the on-air board, designed and built in-house, was dubbed the HFOF-18, a commentary on the speed of the board’s construction — “Hell Froze Over First.”

This HFOF-18 had to be beaten into submission every once in a while. Its summing/output amplifier board would become loose, taking the station off the air, and causing the board to act like a toddler who didn’t get the candy that he wanted.

But there was a spot — a specific spot that when hit with the side of your fist (with admonition to the on-air person to NOT try this on their own) would make the whole world better. Or as good as it was going to get.

Archie shares another of those engineering legends that we hear on occasion.

It seems there was an engineer who had a station that would drop off the air occasionally. The remote control wouldn’t bring it back on, so the guy had to drive an hour and a half to the transmitter site. After checking out the box for two hours and finding nothing wrong, just out of frustration, he hit the transmitter on the side … and it came back on the air!

He then did what any good engineer would be tempted to do: He closed everything up and went home. But about a month later it happened again. So to avoid that three-hour round trip, he came up with a fix.

He bought the largest solenoid he could find, bolted it to the side of the transmitter and hooked it into the remote control. He then rewrote the start-up instructions for when the station dropped off the air: “First dial up channel X, then press up.” When energized, the solenoid would slap the transmitter, the equivalent of smacking it with a fist.

He never did find the problem, but the solenoid saved him that long commute.

Keep panels looking sharp …

Veteran broadcaster and manufacturer Harold Hallikainen read Roy Becker’s tip in that same issue, about using ASA filament and a 3-D printer to “print” plastic signs to identify transmitter sites.

Harold offered a neat idea. You’ve probably seen engraved rack panels. They bring a touch of professionalism to homemade projects, more so than stick-on labels. The problem is where do you get the engraving done, short of buying the engraving machine yourself?

Harold said he created custom engraved front panels by using a black anodized rack panel and taking it to the local awards and trophy shop, where they would engrave the required lettering.

A while back, Harold reacquired a custom relay interface panel that his company had built much earlier for a station in the Empire State Building. The engraved panel looks as good as new, and the lettering never rubs off.

… and faders clean

Paul Sagi writes from Kuala Lumpur to remind us that some slide potentiometers in radio consoles are constructed with plastic elements, which can be damaged by some cleaning solvents. So choose cleaners wisely. Be aware that some solvents are also flammable, so turn off the power before use, and restore it only after all solvent has evaporated.

Paul has successfully used dishwashing liquid and distilled water as a good cleaning agent. After cleaning, shake out any excess water and wait for complete drying at room temperature.

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].