Dan Grimes handles radio broadcast maintenance for the Southwest Region of Faith Communications Corp.

Dan recently took advantage of a Telos-sponsored tips webinar provided by the Society of Broadcast Engineers. He picked up on one of the tips provided by Richard Wood, an independent consultant and principal of Resonant Results Ltd. Richard performs infrared camera inspections for all types of facilities, among other services.

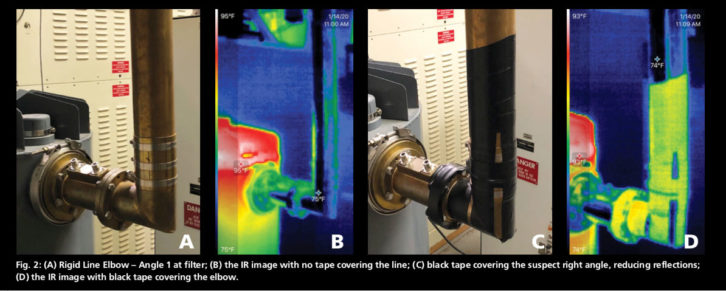

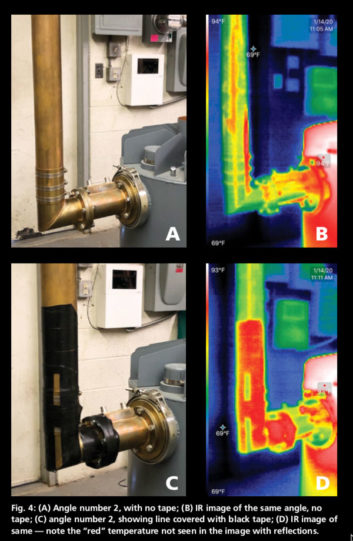

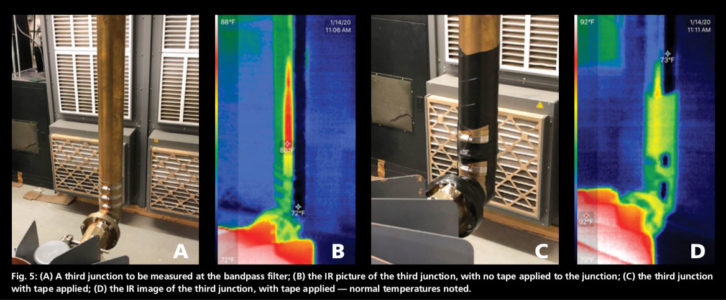

In the SBE presentation, I share some of Richard’s photos, showing “hot spots” detected by his inspections. Many of these are at rigid line junctions, or elbows, where a bullet is overheating and ready to fail.

Richard’s service becomes an insurance of sorts for stations that do not want to endure the catastrophic failure of a bullet and transmission line — potentially costing the station tens of thousands of dollars in repairs and lost revenue.

Dan has been performing this maintenance inspection for the Faith Communications Corp. stations for some time. Dan uses both the Seek IR camera and an Etekcity IR gun. His warning is that both instruments can give false results when looking at a brass rigid transmission line.

The brass is simply an IR reflector, so the reading turns out to be whatever the brass is reflecting. If a cold door is opposite the line, it reads cold. Turn over to the other side where there is a warm transmitter, and it reads hot.

When you have a dilemma, you turn to an expert. In this case, I contacted Richard Wood, who said that false readings are actually common in IR work. The key word is emissivity.

Richard provided a website that discusses the different reflected versus transmitted values of thermal energy from an object.

Richard added that when he took IR training, they showed how to make a highly reflective object easier to “read.” The trick was — yep, you guessed it — Scotch 33 Tape. You cover the area to be measured with the black tape, and then you measure the object, not the reflected IR value.

Higher-end cameras allow the operator to adjust the emissity level of the measurement, but I think you’ll find the black tape is less expensive!

Richard also typically moves around to different angles when testing new transmission lines or highly polished brass and aluminum.

Richard pointed out another key feature in any measurement device — the spot size ratio. This is the pattern measurement area at a given distance. Even though there may be a “laser” pointer, that does not mean that that is the only point measured.

So Richard’s suggestion is not to just “point and shoot.” Instead, put Scotch 33 tape on the elbows you want to measure. Then use the thermal gun at the same physical distance point each time. The result will be repeatable values that can be put in a log. An easy way to accomplish this is to tape the line and an X on the floor for the measurement target and send points.

Dan provided several images to demonstrate this effect “with and without black tape.” The results are seen in Figs. 2, 4 and 5.

Richard Wood and Resonant Results can be reached at 1-608-839-3930.

***

The SBE membership drive is underway. If you opt for SBE MemberPlus membership, you’ll have access to the library of all SBE webinars — including the Workbench Tips Webinar.

These webinars are an excellent resource for engineering education — whether you’re new to the industry or an old salt like me, but still learning!

Head to www.sbe.org for more information.

John Bisset has spent 50 years in the broadcasting industry and is still learning. He handles western U.S. radio sales for the Telos Alliance. He holds CPBE certification with the Society of Broadcast Engineers and is a past recipient of the SBE’s Educator of the Year Award.