There is at least one small upside to COVID-19, which is that we have more time to catch up on things around the station or workshop. Empty studios give the engineer free reign for both cleaning and maintenance. Funny how there’s still so much to do!

Professional Engineer (P. E.) Buc Fitch has come up with a great cable test kit for the entry-level engineer, intern or assistant to build. It’s fun for more seasoned engineers too. After all, why should the new guy or gal have all the fun?

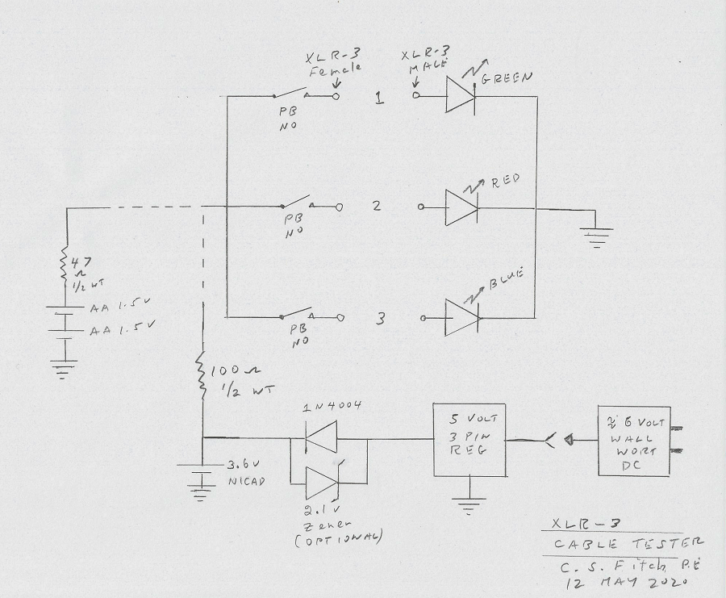

Buc’s “kit” is, as he puts it, is an “uber-simple XLR-3 cable tester.” Its purpose is to test XLR-connectorized cables for proper wiring and polarity. We’ve simplified the circuit description; hand the rest of this article to your intern and let them figure it out.

First, let’s talk about XLR polarity. It’s important!

A few years ago, I was visiting a customer who was having problems wiring up a mic cable. The internet said Pin 1 was hot! The internet is a great tool only when it’s used properly. Standard mic wiring, at least in the United States, is Pin 2 hot or +, Pin 3 i negative or – , and Pin 1 is ground. As with any tool, it must be used properly. So double-check what you read on the internet by visiting several sites or asking a fellow broadcast engineer.

Buc’s cable tester will avoid this wiring problem, permitting you to verify all your XLR cables. You may be surprised to see how some cables, especially in your remote kit, are wired!

This project can be assembled with junk box parts; nothing is really critical. Buc’s schematic sketch shows power via battery or wall wart, your choice.

In the center of the schematic are the chassis-mounted XLR male and female connectors. One thing to remind the intern is that the pins flip or “reverse” from one connector (female) to the other connector (male). Be sure to check the pin numbers on each connector before soldering.

The three pushbutton switches are simple N.O. (normally open) chassis mount switches. The LEDs are not critical; Buc chose red, green and blue. LED current is limited by either the 100 ohm or 47 ohm half-watt resistors, depending on the power supply used.

As for the power supply, the simplest is shown to the left: two AA batteries mounted in a simple two-battery holder.

AA batteries provide 1.5 VDC each, and since they are wired in series, the total voltage is _____?

For the wall wart supply, the approximately 6 VDC wall wart plugs into a jack on the side of the chassis box, and feeds a 5 VDC three-pin regulator. Its output connects to a 1N4004 diode in parallel with an optional 2.1V Zener diode. Again, watch the polarity!

A nice feature that Buc added to this box is the 3.6 Volt NiCad battery, which is rechargeable and permits operation without the unit being connected to an AC power source. The NiCad will be charged when the wall wart is plugged in.

By the way, the longer horizontal line on the battery symbol is the “positive” side of the battery.

Construction is not critical and any small chassis box will work. Use one like those in Fig. 2 (the ones shown are from a different project).

If you build one of the cable testers, send in a high-resolution picture to [email protected]. And for another fun project, read Buc’s article “Build an Unbalanced to Balanced Adaptor.”

(Two 1.5V batteries connected in series gives you 3 Volts, did you get it right?)

Stick These Somewhere

Eventually many of us will return to our radio stations and offices. New York Printing Solutions is providing a variety of large-format printed floor stickers and wall decals that you can use to remind employees about social distancing, wearing masks and other customized messages.

These are full-color vinyl indoor/outdoor, scuff-resistant decals. They are removable and leave no residue. They can be customized with your station logo.

You know that I like to see engineers work with other department heads; well, here’s an idea: Print a bunch of these up with your station logo and distribute to advertisers that serve the general public.

The company prints everything from business cards to foam-core posters, and finding the COVID-19 stickers took a little navigation. Visit www.nyprintingsolutions.com/floorstickers/.

Honey, Where’s the Shower Curtain?

I’ve had several email discussions with Todd Callahan at KUT Radio in Austin, Texas. Todd was looking for some kind of cover to protect his AoIP surfaces from both dust and dirt, as well as cleaning compounds that may be used to disinfect studios.

A natural choice is a custom-made furniture slip-cover. A great idea, but when he started pricing them … whoa, expensive!

Here’s a better choice: A clear plastic shower curtain can be trimmed to fit pretty much any size console or surface. The edges can be held in place with strips of ScotchBlue Original Multi-Surface Painters Tape. The tape will keep the edges secure for up to two weeks and can be removed without leaving residue.

John Bisset has spent over 50 years in the broadcasting industry and is still learning. He handles western U.S. radio sales for the Telos Alliance. He holds CPBE certification with the Society of Broadcast Engineers and is a past recipient of the SBE’s Educator of the Year Award. Email tips to [email protected].