Doug Fearn, K3KW, tells a story about a toolbox.

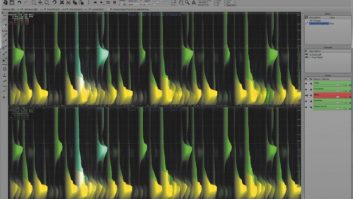

But first he wanted us to see this throwback photo that he took at WPEN(AM). It shows the old Master Control room, built by RCA in 1947.

Doug started working at the station as a senior in high school. He says that when he got there, the studio had changed little since the 1940s except for the addition of a rack with three cart machines, newer turntables and three Ampex tape machines (note the bank of remote start controls to the left).

Doug notes that this was before the days of “combo” operation; the station’s announcers had a cough switch and talkback button, but an engineer ran everything else.

Later Doug would supervise construction of new studios up the road in Bala Cynwyd for WPEN and sister station WMGK(FM), both owned at the time by Greater Media.

But Doug wrote to us to share a memory prompted by our discussion of toolboxes. In 1978 he was driving home from his recording studio with a console power supply in his trunk. The supply was defective, and Doug was taking it home to fix it ahead of an important recording session.

But he never got home that day because his car was struck by a vehicle driven by a drunk driver. Doug woke up in a hospital suffering from multiple injuries.

Yet that console had to be operational for the upcoming session. So once he had his wits back, Doug — from his hospital bed — asked one of his employees to go find his car and bring that power supply to his room, along with a metal toolbox Doug kept in the car.

His employee found the mangled Volvo and brought back the supply and the toolbox, and yes, Doug then proceeded to repair the supply on his hospital bed!

And the recording session went on as scheduled, even though Doug himself wouldn’t be discharged for another two weeks.

Crazy, maybe! Yet I’m sure every engineer reading this will take pride in how Doug handled this experience. Because we always get the job done!

As for the toolbox, Doug did his best to pound it back into shape, though some of its welds and seams were broken in the car crash. The toolbox, along with its dings, now lives under his workbench, holding tools that he doesn’t use often. It serves as a reminder both of that awful accident but also how the box and its tools helped him save a recording session.

Bill’s “Go Bag”

Bill Moede recently retired from Cumulus, where he took care of a cluster of 11 stations and two translators spread around most of northeastern Wisconsin.

He says that in addition to a toolbox, he kept a “Go Bag” in his truck containing a change of clothes, a backpacker’s compact sleeping bag, protein snack bars, a first aid kit and an envelope with emergency cash. He also kept a case of bottled water in the truck.

While we tend to focus on tools we need, Bill’s list is a reminder that we should also be prepared for the unexpected, especially when we service stations over any considerable distance. Congratulations, Bill, on your retirement, and thanks for reminding us of these important items.

Keep a list

And San Francisco’s Bill Ruck wraps up our column with a reminder that’s helpful for everyone but especially contract and project engineers who own their tools.

Over the years Bill has had to replace tool bags that had been stolen, so he got in the habit of creating an inventory to help himself in the event he’d have to file an insurance claim later. Bill writes a list for each box describing every tool, its SKU or part number, its manufacturer, the date purchased and the cost.

Let’s face it, tools are expensive. Protect yourself by making a list of what you own.

As to size, Bill has used larger boxes, but found that when filled, they get almost too heavy to haul around. Nowadays he limits himself to a smaller bag that limits the weight. He keeps bigger construction tools in drawers in his van. Several large transport cases hold hardware, wiring and soldering supplies.

The U.S. Navy taught Bill the importance of using the proper crimp tool, so he keeps a large selection. In fact, if he is working on something and doesn’t have the manufacturer’s recommended crimp tool, he will buy it.

As far as individual tools, Bill recommends the Klein 32500 Multi-Bit Screwdriver/Nut Driver 11-in-1 set, which includes Phillips, slot, square and Torx bits plus nut drivers. This single, high-quality screwdriver can take apart most anything. Bill also learned to leave Harbor Freight straight slot and Phillips screwdrivers at his various transmitter sites, just to minimize trips back to his van.

Yet no matter how organized you are, Bill adds, there will be times when on the top of the mountain you will find yourself saying: “If I only had that one other tool.”

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].