This is an archived article that originally appeared as part of a series to help readers prepare for SBE certification exams. We posed pose a typical question in each column. Although similar to actual questions, these were not from past exams nor would they be on future exams in this exact form.

Here’s the certification-style question we posed in a prior issue, followed by our discussion:

You are preparing an executive summary for management outlining the projected cost of various aspects of new facilities at your station. You need to calculate the wire size for the main power feed to the remote truck.

This truck will be used as the ultimate studio backup in the event of a long-term utility power outage. The HVAC and terminal equipment in the truck make this a notable load, so the wire is a large part of the cost. An NEC requirement is to limit voltage drops at the load to under 5 percent of the nominal supply voltage.

The worst-case load, with both HVAC units running on a 95ºF day and all lighting and gear running, is 62 amps at 240 volts. The wire distance to the trucks reserve parking space is 250 feet.

Ignoring power factor (PF) and incidental issues, from the panel CB to the local disconnect supplying the truck, which size wire will limit the voltage drop to under 5 percent?

a. #18 copper TW

b. #16 copper TW

c. #12 copper THHN

d. #8 aluminum USE

d. #4 copper THHN

DISCUSSION

Besides the technical side of the instructional questions poised in this column, we’ve often discussed the nature of test taking and the style of questions as well.

In general, questions can be categorized at the extremes as “too much information” or “minimal information” questions. The above is an example of the former. Stripping out the extraneous (too much information), what remains is this:

- — We need to limit the voltage drop to less than 5 percent of the supply voltage.

- — The considered current load is 62 amps.

- — The supply voltage is 240 volts.

- — The length of the cable is 250 feet.

- — Only one answer is correct.

Overall, the purpose of these SBE certification exams is to confirm your practical and formal knowledge of the technology and regulations that make up the core of our industry. The precise purpose of this question, although buried in rhetoric, is to test your general knowledge about wire sizes and their capabilities.

I’ve always felt that the way wire sizes are numerically described is counterintuitive. One would logically think that the bigger the wire, the bigger the associated number should be for that wire size. The reality is the reverse.

In the early days of wiring America, competing firms and technologies had unique and varied ways and numerology to describe the sizing of wires. To bring order from chaos, near the turn of the last century, the Brown and Sharpe Company standard became the standardized American Wire Gauge (that’s the AWG you see on wire boxes such as the 12-2 with ground romex you buy at Home Depot). B&S’s system essentially doubled the volume of the wire every three numbers and defined precise cross section dimensions for each size. Most wire was solid at that time and made from molten copper pulled through a die (extruded).

The question-level is CPBE level, so we can assume that the person taking the exam has at least 20 years of quotable, employed industry experience. Wires make up a major part of our systems and installations. A practitioner at this stage in his or her career without knowledge of wire types, sizes and use deserves to fail.

A quick glance at the answers would indicate that answers (a) through (c) are incorrect on their faces, as their current carrying capacity in power handling applications is under 30 amps. Also, the National Electrical Code, which governs electrical power wiring in the United States for approval and insurance purposes, will not allow a conductor smaller than a #14 to be installed in a power supply application such as this in a commercial installation.

The NEC allows the use of both copper and aluminum wiring for most power purposes with the current rating of a comparable-sized aluminum conductor proportionately less than copper (aluminum has less free electrons). So answer (d) could possibly be dismissed because the smaller size of this wire limits the answer to the single and last selection, (e).

Although the question appears to be complex, your practical knowledge should take you quickly to the probable answer.

However, suppose that the choices were all quite similar-sized wires. Then the question would become a calculation exercise.

Besides the “The National Association of Broadcasters Engineering Handbook,” “The ARRL Handbook for Radio Communications,” “ITT Radio Engineer’s Handbook,” “Electronic Communication” by Robert Schrader and maybe “Radio Handbook” by William Orr, you should also have a copy of the National Electrical Code, published by the National Fire Protection Association, or Dr. Eugene Key’s “Principles of Electricity” that we all used in undergraduate or tech school.

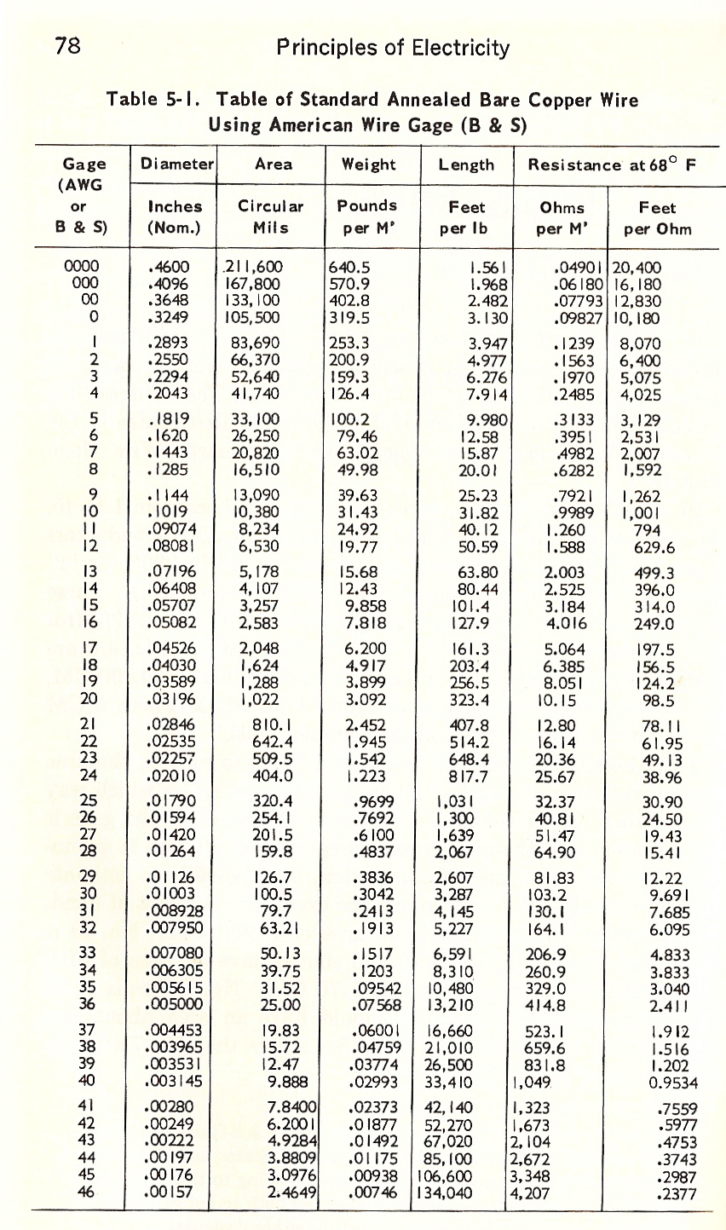

Since we can ignore all other factors, the wire resistance becomes the limiting dynamic in our calculation. Since we have a probable answer on its face, let’s consider the #4 THHN copper conductors. We have 250 feet out and 250 feet back of #4 copper. From Table 8 in the 2008 edition of the NEC, we have a per foot resistance of 0.000321 ohms (0.321 ohms per 1000 ft) for typical coated wire as you usually find in THHN manufacture.

Calculating the exact answer:

500 ft times 0.000321 ohms per ft = 0.1605 ohms total wire resistance for 500 ft

62 amps times 0.1605 ohms = 9.951 volts drop

9.951 volts drop divide by 240 volts = 0.0415

Converted to percentage = 4.15% (which is under 5%)

Our distinguished and super-punctilious editor has noticed that various tables for wire resistance often differ. The values in the NEC tables are calculated to reflect the anticipated operating temperatures, wire coating (if present which attenuated cooling) and the environment inside of the usual insulation encountered in these conductors based on values supplied by the National Bureau of Standards.

The table that accompanies this article is for bare wire resistance at 68ºF. Wire resistance increases with temperature essentially at a proportional value of very nearly 0.00218 per degree F for this bare wire.

A piece of electrical trivia most practitioners do not know is that electrical wiring has to be made from virgin copper. Other copper products such as motor cores, radiators, house flashing, etc. can be made from reclaimed copper, as the wide variation in electrical conductivity found in reclaimed copper is not important.

I’ll leave you to do the calculation for the #8 aluminum.

The deadline for signing up for the next cycle of SBE certification exams is June 4, 2010, for exams given at the Local Chapters between Aug. 6–16.

Charles “Buc” Fitch, P.E., CPBE, AMD, is a frequent contributor to Radio World.

Question for next time:

This Sunday night you are going to install a new HDFM exciter, which also generates the composite stereo signal. Are you required to do performance measurements?

a. No, as long as there is no change in modulation level.

b. Yes, because you’re a professional and you want to know that the station is measured perfect no matter that the program director says his “golden ears” are better than your test gear.

c. No, there is no FCC mandate to do this, and anyway performance is set by the manufacturer’s checkout.

d. Yes, under the general guidelines of 77.12966 b.3 any equipment change requires performance measurements.

e. Yes, 47CFR73.1590(4) requires performance measurements when a stereo generator is first installed.