You work on transmitters every day. Have you ever removed a large tube socket for repair or replacement? It can be a daunting task.

I hope you don’t have to do the job overnight when you are tired. Mistakes are made easily and can be difficult to figure out later. Plan on taking a few hours, even a day. Don’t be afraid of the job but understand that you need to work in a logical way. Take photographs as you go along; it can help immensely during reassembly.

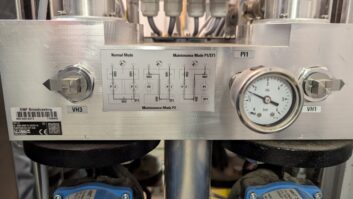

Fig. 1: Top of tube socket with small wrench. Fig. 2: Bypass capacitors around the tube.

Fig. 1: Here is the top side of a tube socket for a 4CX15,000A tube in an RCA BTF-20E 20 kW FM Transmitter. Lots of pieces in a small area. You can never have too many tools when doing this work. That adjustable wrench is just 4 inches long. It is exceptionally handy in tight spots.

Fig. 2: Here is the socket with the screen contact ring removed. Look closely and you will see something is a little odd on the left side of the right-hand screen bypass capacitor.

Fig. 3: Capacitor dielectric that has been arced through. Fig. 4: Socket removed from PA cavity.

Fig. 5: Failed socket spacer on the right. Fig. 6: Using a tube to get socket parts exactly in place.

Fig. 3: Sure enough, the insulator material failed, causing a short in the screen circuit. You can see an arc-through near the top. Careful visual examination is an excellent troubleshooting tool in most cases. Fortunately there was a spare part at the site. Spares are a wonderful thing!

In this transmitter repair adventure, that screen bypass was not the only problem. The entire tube socket had to be removed for bench repair.

Fig. 4: Note a scattering of hardware in the bottom of the PA compartment. A piece of cardboard was placed over the incoming air duct to keep parts from falling into the cooling fan. This is also a good time to replace any burned or broken fingerstock.

The most likely failure occurs on the innermost filament contact ring. It carries the same current as the next ring out, but is much smaller. The second ring is the other side of the filament. Current is 160 amperes in the case of a 4CX15,000A tube, which is enough to start a car engine. No wonder the filament leads need to be heavy duty.

Fig. 5: On the bench, a nylon spacer/insulator was discovered to be the reason why control grid voltage went to nearly zero at times, resulting in sudden PA overloads. You can see the insulator discolored brown to black on the right side of the socket. Since those are no longer readily available, I used a porcelain insulator as a replacement. This change in capacitance is enough to throw neutralization off. Checking and adjusting neutralization afterward is a good idea when making changes to the socket for a tetrode (4CX) tube.

Triodes (3CX) don’t require neutralization, as they do not normally have enough gain to go into oscillation. After the insulator was replaced, the tube socket needed to be reassembled. It is extremely important to get the socket contact rings aligned properly. Failure to do so could cause undue physical stress on the tube causing an air leak at one of the seals and total tube failure.

Fig. 6: The best way to get the socket geometry right is to use a tube as an alignment tool. Carefully tighten the hardware as much as possible, then remove the tube and do the final tightening. Recheck to make sure the tube fits easily into the socket. Inspect fingerstock to see that it equally depressed on all sides of the tube. Sideward pressure in only one direction on a hot tube seal is a formula for tube disaster.

Fig. 7: Testing bypass capacitors on the bench. Fig. 7: Here the socket insulators and bypass capacitors are being tested using a Sencore Z Meter to see if there is any leakage at 600 Volts. This is the best time to find a problem like that, rather than after the socket is back in the transmitter.

Fig. 8: Installing a screen grid ring in transmitter. Fig. 8: Back in the transmitter, the screen ring had to be installed and tightened after the rest of the socket was in place. Again, a tube was used as a jig to get the alignment correct. A right-angle screwdriver with ratchet was ideal for final assembly in this case. Note the black permanent marker line on the socket and transmitter cavity. That helped get parts back in the original orientation. You can get into real trouble in a hurry if you don’t think it all through first, and by marking as you go.

If you run short on hardware, use only copper, brass or stainless steel in an RF situation. If the hardware sticks to a magnet, it is ferromagnetic and will tend to vibrate at the RF frequency involved. This could lead to the hardware melting in the presence of high power. I have seen it happen. Some plastic or nylon screws and nuts are OK in RF and others are not. If you hear a loud pop when RF is turned on, then you will know the hardware you used was not RF compatible.

Take time to confirm that all hardware is tight. Cooling fan vibration can easily loosen bolts and nuts that were not snug at installation time, resulting in bad electrical connections and erratic transmitter operation. This kind of project is not for the faint of heart. Also, it helps to have mechanical skill. If you are the person who has trouble deciding if a square peg goes in a square hole or in a round hole, it is best to have someone else help with the tube socket mechanical work. Don’t laugh; I have run into otherwise great engineers like that.

Double check the work and use an ohmmeter to verify there are no unwanted shorts before turning power on. Just think it through and you should be fine.

Mark Persons, WØMH, is a certified professional broadcast engineer by the Society of Broadcast Engineers and has over 30 years of experience. He has written numerous articles for industry publications over the years. His website is www.mwpersons.com.