A recent Radio World ebook explored trends in transmitter design and applications.

This interview is excerpted from the ebook. WAMU 88.5 American University Radio is “Washington’s NPR station.” Rob Bertrand is senior director of technology. Andy Gunn is director of engineering.

Radio World: When you are considering a transmitter purchase, what is your approach?

Rob Bertrand: One of the biggest considerations is asking, how will this improve our overall efficiency as a business. There are technical answers — considerations around power efficiency or cooling requirements — but I’m also interested to know what support will be like.

Will this transmitter require less time to maintain than its predecessor? And when evaluating brands, what features might make maintenance simpler or more complex?

We recently rebuilt the full main and aux transmitter facilities at WAMU. Our goal was to minimize the amount of time someone needed to regularly have “face time” with the transmitters.

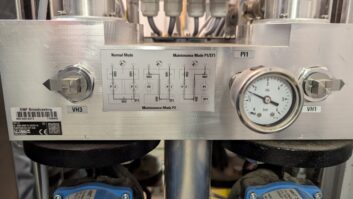

We deployed good old-fashioned GPIO control and status monitoring with our remote control systems, but we also integrated rich data via SNMP from our transmitters. This way we get the best of both worlds: the reliability and consistency of GPIO that is rarely disrupted with a software update or configuration change, and the additional visibility brought through SNMP monitoring.

We invested in redundant air chains of audio and support equipment, as well as redundant exciters for each transmitter. The goal was that we could suffer a failure anywhere in the plant and still have an operational transmitter. With liquid cooling and electrostatic filters on our HVAC systems, even filter maintenance is reduced.

While we do make regular visits, the goal was delivering a facility that if other objectives kept us away for some time, the site would keep on ticking even without regular intervention.

Andy Gunn: Time is always my limiting factor — time to perform routine maintenance, work on new projects or respond to issues as they come up. I’m most interested in building systems that will save me time in the long run — reduced maintenance time or shorter time to repair or bypass in the event of a failure — even if the initial installation or setup takes a few days longer.

The availability of parts and the stability of the manufacturer are major considerations. How would you obtain replacement parts? Does the manufacturer have a parts depot nearby or close to a shipping hub? Do they have a service center nearby?

Modern transmitters have similar feature sets — high efficiency, support for all HD modes and power levels, hot-swappable modules, and detailed telemetry and monitoring. The form factor, cooling and build quality can vary, though all the transmitters above 10 kW that I have worked with in the past 15 years have had very good build quality.

RW: For someone who hasn’t purchased a transmitter in some time, what recent developments should they know about?

Bertrand: I really think that above a certain power level, liquid cooling is a game-changer.

When I arrived at WAMU in 2016 I inherited a plant that, for several reasons, was supposed to be temporary. The transmitter, a wonderful modern model, was oversized for the air conditioning in the room, which had long outlived its own useful life. So the compressors never shut down and, as you might imagine, they failed altogether sporadically because they never stopped running.

This would create a vicious cycle where the emergency exhaust fan would then kick in, you get the picture. On a hot July day in Washington, this was not a good situation.

Being part of American University, my colleagues in central plant dutifully engaged an engineering firm to design a replacement HVAC system for us. Our cooling requirements far exceeded what a pair of split systems could deliver, particularly when factoring additional solar load, so the only choice was to go to a package system.

When all was said and done, I was left with the choice to spend nearly the same amount on a properly sized package-type HVAC system, or I could install a new liquid-cooled transmitter and kick the HVAC replacement down the road a few years.

I installed the liquid-cooled transmitter, and our problems went away literally overnight. Our power consumption dropped dramatically, and our stability increased significantly. The emergency notifications from the monitoring systems — or worse the actual power dips on the air that we were dealing with when I got here — evaporated.

Gunn: Modern transmitters contain a huge wealth of monitoring points — to the point where it may be overwhelming to decide what to monitor. While your main transmitter functions and alarms should always be tied into your remote control with physical GPIO wiring, having the rest of your transmitter data available via SNMP can be a boon to observing trends or catching early warning signs of a problem. While a summary alarm may let you know that there is a problem with the transmitter, having that additional data can let you know whether it was a small issue, or a major one.

I recommend spending time going through the transmitter’s own interface to find the most critical data points — for example, cooling loop pump flow rate, loop pressure, cooling fan speed, etc. These can be vital when troubleshooting an issue that a single “Major Alarm” cannot.

The flip side is that you need a sufficiently powerful and advanced remote control system to handle the number of data points from GPIO and SNMP that your transmitter and other site systems have available. While it may seem fine to skimp on the physical GPIO interfaces, I trust a pair of wires more than SNMP, which is reliant on outside network systems as well.

If you’re planning on getting a new transmitter but have a very old or very simple remote control system, I recommend upgrading this and planning out new wiring and break-out cables for ease of maintenance. Your future self, or engineers that inherit your site, will thank you.

RW: We hear a great deal about virtualization of the air chain. What are the implications for how transmitters are designed and how users will choose and configure them?

Bertrand: My knee-jerk reaction is that I really don’t want to see transmitter manufacturers getting into this business. Transmitter technology evolves slowly, while the IP-based technology used to deliver this kind of content evolves quite rapidly. The last thing I would want to have to worry about is marrying rapidly evolving (and somewhat prototypical) needs with the more stable and slower-shifting transmitter market.

Whatever solutions are chosen to deliver cloud-based air chains to the transmitter plant should remain separate and apart from the transmitter itself.

It’s likely that if you are large enough to warrant leveraging this delivery mechanism, you are also going to want to leverage identical monitoring and control systems across your sites. Very few companies are in the position of being able to replace that architecture and their transmitters at a given site simultaneously.

It’s an important trend but I think it should evolve and mature outside the world of transmitter hardware.

Gunn: I don’t see this as being particularly helpful in a transmission chain outside of audio processing in an AoIP environment. Even there, I would be hesitant to have any virtualized systems in my main air chain. While most high-end audio processors are simply software appliances, the ability to physically bypass and produce a stable composite signal for the analog FM portion of a transmitter is too valuable to virtualize away.

However, as streaming and on-demand listening grow in market share for stations, there may be opportunities for virtualization in the processing and delivery systems at a station. If the virtualized systems can utilize AoIP, the transition here would make sense.

RW: How do consumer trends and new platforms like smart speakers, apps and voice-controlled car infotainment systems affect how a manager should plan a transmitter purchase, if at all?

Bertrand: I think the strategy should start at a place of clearly identifying the places where we are delivering our greatest value and steer our investments accordingly.

Since I’ve been at WAMU, we have divested five FM signals over five years. As someone who loves over-the-air broadcasting this has been somewhat painful. However, as we looked at the audience and revenues associated with these repeater stations, it just wasn’t defensible.

It will be different in different areas of the country; geography and internet availability means that similar FM networks still make sense in certain places. But in the Washington, D.C., region, our data showed us that it was really only our primary signal that was delivering meaningful audience.

[These changes] resulted in minimal revenue drop and near-zero audience drop. We lost those big recurring expenses, and we took the capital from those station sales and reinvested it into our primary and backup facilities for D.C. — buying four new top-tier transmitters, building a new FM combiner and antenna system, and making critical infrastructure investments to our facility there.

In terms of the digital side, this has also enabled us to direct more investment to those operations. We require fewer engineering hours to maintain such a complex and far-flung set of transmitters, so our engineering team is better able to focus on supporting content production in-house, making sure that our studio facilities can produce all the products we’re growing, and that our streaming architecture is receiving the same level of attention as our RF infrastructure.

We’ve done all that without reducing staff, and also without adding engineering staff. We are just spending our time differently.

So as a station is thinking about how to handle transmitter purchases — I think it should be done carefully and with consideration for the highest value proposition.

RW: What other questions should transmitter buyers be asking?

Gunn: What does a manufacturer’s full on-site commissioning package offer, and what does it cost?

If you are not familiar with liquid cooling or need help preparing your site for a new transmitter, what can the manufacturer offer you to help?

These days broadcast engineers are expected to handle more and more of a station or group’s technical needs, but have extremely limited time. Being able to lean on the manufacturer for help with the hands-on installation, setup and testing of the transmitter can be a big relief. It can change a two-week process into one week, or even just a few days. Having a site visit by a technician or installer in advance can also help resolve any issues that will be roadblocks to a smooth installation.

We all pride ourselves on our ability to learn new systems and be able to do it all ourselves, but there is something to be said for spending a bit of money to save a lot of time and have the peace of mind of working with someone who has done it before. You might learn a few things along the way.