It wasn’t too long after I started fooling around with computers in the mid-1980s that antenna modeling became a thing. NEC and MININEC were the prevalent modeling engines, and the source code was out there in the public domain.

At some point, I began playing with models of medium-wave monopole antennas, simple nondirectional radiators. While those simple models were somewhat useful, they didn’t really do a whole lot for me. Now, if I could model a directional array and get an accurate prediction of the driving point impedances, that would be worth something.

And so it was that I started playing with directional models. The challenge was not in the physical geometry of a directional array. It was coming up with a set of drive voltages and phases. I experimented but had little to no success, and I eventually gave up, moving on to other, more pressing things.

Eureka!

Fortunately, some very smart people were working on the problem, people like J.L. Smith, Ron Rackley, Jim Hatfield, Jerry Westberg, Ben Dawson and others.

They figured out that you had to compute the individual tower current moments for unity drive, then with that information and the theoretical directional parameters, solve a set of simultaneous equations to get the normalized drive voltages.

Those drive voltages, each expressed as complex numbers, could be applied as sources in the model, and the resulting tower moments would equal the theoretical directional parameters.

After the brain trust figured that out, I was able to write some code and create a computer program that would do the whole thing, taking array geometry expressed in either X,Y,Z format or in distance/azimuth from a reference tower, then taking the theoretical directional parameters (ratios and phases) and turning that into a model that I could calibrate to real-world impedance matrix measurements and produce an output including driving point impedances, voltages and currents; element current distribution, and both near- and far-field E- and H-field values.

New FCC rules permitting “proofing” of AM directional arrays went into effect in 2008. I filed my first model-proof that summer, and I’ve never looked back.

The moment-method modeling proof option has been great for our industry. Aging arrays that needed a lot of very expensive fieldwork could be brought into adjustment very quickly in many cases, and new installations could be tuned up in days if not hours.

Today, you can look through the FCC database and you’ll see many occurrences of the telltale file number prefix “BMM,” indicating a moment-method proofed facility. Many of those are model proofs I have filed.

Needless to say, I’m still a believer.

The trap

Fast forward to 2021. Last year, a group of engineers and broadcasters (more really smart people) petitioned the FCC for a rule change that would allow model proofing of FM directional antennas. That rulemaking, at this writing, is in process.

FM directionals, which constitute a reported 20% of all full-power FM facilities, have long been a problem for engineers. I got caught in the FM directional “trap” back in the mid-1980s and had to petition the FCC for a variance to get a facility on the air.

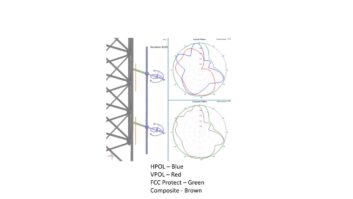

The usual process is first to determine the maximum ERP in every direction of interest, whether a target service area or toward a protected station or border, then develop a theoretical antenna pattern based solely on the coverage and protection requirements.

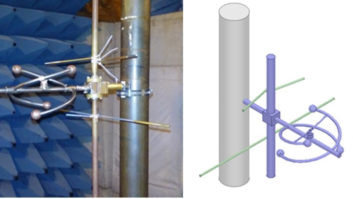

That ideal or “envelope” pattern then is specified in the construction permit application. When the CP is granted, the envelope pattern is sent to the antenna manufacturer, who will do range measurements using a model based on detailed information about the mounting location provided by the permittee. The manufacturer will make tweaks, adding and moving around parasitic elements to get as close as possible with the measured pattern to the supplied ideal or envelope pattern.

The “trap” occurs in that zone between meeting all the protections and making the required RMS, which by law must be 85% of that of the authorized pattern. Sometimes the measured pattern will meet all the protection requirements but come up short on RMS. That’s what happened to me way back when.

The sure-fire way to avoid this situation is to have the antenna manufacturer develop a buildable, measured pattern and file that pattern instead of the envelope or ideal pattern with the CP application.

Then, when the time comes to file the license application, that same pattern is filed as the “proofed” pattern. All protections are met, and the RMS is 100%.

But that entails some financial risk. You have to pay the antenna manufacturer to develop and fully proof a pattern, with no assurance that the FCC will grant the application. That risk can be minimized with careful attention to detail in the application process (and leaving some white space between interfering and protected contours), but if there’s one thing I have learned from 40+ years of filing FCC applications, it’s that anything can happen.

Remember those smart people I mentioned, the ones who have petitioned for a rulemaking that will allow model-proofing of FM antennas? Their proposal will solve the problem of the “trap” as well as saving all the time, trouble and cost of FM directional antenna range measurements.

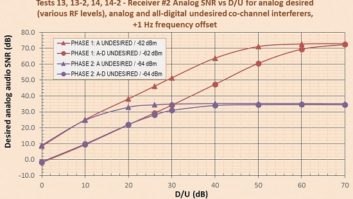

In the latest issue of RW Engineering Extra, we feature a white paper on computer modeling of directional FM antennas by John Schadler of Dielectric. John provides some compelling arguments for this, and I think you’ll find it interesting.

I’m going to go out on a limb here and predict that the FCC will very shortly enact the requested rule change in some form to permit model proofing of FM directional antennas. While there are differences, the engineers at the Media Bureau have certainly seen the benefits and reliability of AM model proofing, and that undoubtedly carries some weight.

The result for broadcasters will be no more RMS/protection traps, no more range measurements, and a reduction in time between order and delivery of custom directional antennas. Patterns can be fine-tuned to fit the application with engineering time being the only cost.

I think that’s pretty doggone cool.