The author is editor in chief of Radio World.

One of the best parts of my job is presenting the Workbench column in our pages.

Workbench was well established by the time I joined RW in 1996. Sometimes the smartest thing that the editor of a publication can do is support a good thing and get out of the way.

With this issue we celebrate 30 years of John Bisset writing Workbench, and salute the hundreds of readers who have provided the tips that are at the column’s heart.

Getting Started

When RW’s founder Steve Dana sought to expand Radio World and its tech content the Workbench column was born. At the time, John was a chief engineer who had written product reviews for RW; he also taught a college-level broadcast engineering class part-time and enjoyed teaching.

Workbench quickly became popular and secured its place as a feature in every issue.

John had gotten his own start at age 12 by building what today would be considered a pirate top 40 station. (You don’t know how often I hear stories like that from people in our biz). He hooked a Lafayette mike mixer up to a couple of turntables and a reel-to-reel fed a Lafayette Wireless Mike AM transmitter. The station had about a two-block coverage.

John was always hanging around radio stations (again, sound familiar?) His first professional job was at WFAX(AM) in northern Virginia, serving the Washington area.

“Program Director Roy Martin hired me as a summer relief announcer, when I was 16. I worked there part-time through high school and college, and joined the full-time staff after graduation.” Around that time he received training in technical writing with an influential teacher, Professor Joey Horobetz.

Eventually John was promoted to WFAX chief engineer, and the same year fellow engineer Henry Stewart and he started a contract engineering business.

“I got into equipment sales by learning from Joe Novak at Delta Electronics. Later stops included Harris, Dielectric, Broadcast Electronics, Nautel and Elenos.” About eight years ago he joined Telos Alliance, where he is radio product sales manager for the western U.S.

John and I both seek to make sure that the column’s content is fair and thorough and not favoring any manufacturer, including those for which he has worked. John adds a hat tip to Telos for being so supportive in providing him time and opportunity to educate engineers on topics like AoIP and studio construction, in RW as well as other platforms.

Grab the Bubble Wrap

The column’s relationship with its readers is crucial.

“Over these 30 years, hundreds of engineers, programmers and managers have sent in tips and photos from all over the world,” John pointed out.

“Published tips qualify for SBE recertification credit,” John reminded me. But he’s especially proud of the programming and management readership of the column.

“I try to explain the tips and subject matter in such a way that the non-technical or semi-technical reader can use them, as well as the seasoned broadcast engineer.”

Have any reader tips stood out as most useful? He laughed.

“As I’ve gotten older, something to protect your knees when you’re kneeling in the back of a rack, under a console or in a transmitter — with the power off — that’s where bubble wrap comes in handy. Keep a few sheets in your service vehicle and at each site.”

(John, this is classic Workbench stuff. MacGyver would be proud.)

“Using a cell phone camera to document things ranks a close second,” he continued.

“Use the camera to take pictures of smoked components, animals you encounter and parts. Parts photos can be shared with a service department when you are missing a manual and need to identify something.” A camera also lets you share pictures anonymously with Workbench or just with your own station staff.

“Let’s face it, other than engineers, few employees of a radio or TV station understand what the transmitter site is all about. Posting pictures of exploded parts, dead snakes or raccoons that have taken up residence are great conversation starters.”

What about strange or unexpected submissions?

“Shortly after the column started, an engineer sent in a modification to an old transmitter,” he told me.

“The tube transmitter was atop a mountain several hours away, and occasionally the plate breaker would trip, turning the rig off.”

The engineer could never identify the problem and got tired of the two-hour drive.

“Frustrated, he mounted a cart machine solenoid to the front of the transmitter, right above the tripping breaker. He drilled a hole in the end of the breaker and connected a line to the solenoid plunger. The solenoid was connected to the remote control, so that when the breaker tripped, it could be reset ‘remotely’ by energizing the solenoid,” John related.

“I could see both sides of this solution. It’s not necessarily good engineering practice to remotely switch a breaker, because you don’t know why the breaker is tripping in the first place. But repeatedly driving two hours to simply flip a breaker on had to be pretty frustrating.”

He took heat from some readers who felt this idea was reckless; but many thought it was a genius solution to a problem that a new transmitter later corrected.

Efficiency

I asked John how the column has changed.

“In the early days, there were a lot more tips on modifying or troubleshooting equipment,” he recalls.

“There were engineering staffs consisting of a chief and a couple of maintenance engineers and maybe a transmitter tech. Today, one guy does it all.” And “all” now includes multiple stations for many engineers.

With that evolution, he focuses more on improving an engineer’s efficiency.

“The maturity of software-based products has made this possible. Features can be added or bugs addressed with a simple software update. The equipment is also more reliable, and in most cases modular, so many repairs involve simply swapping a module.”

Parts may be swappable but it’s hard to imagine Workbench without him. Thank you John for your contributions and hard work.

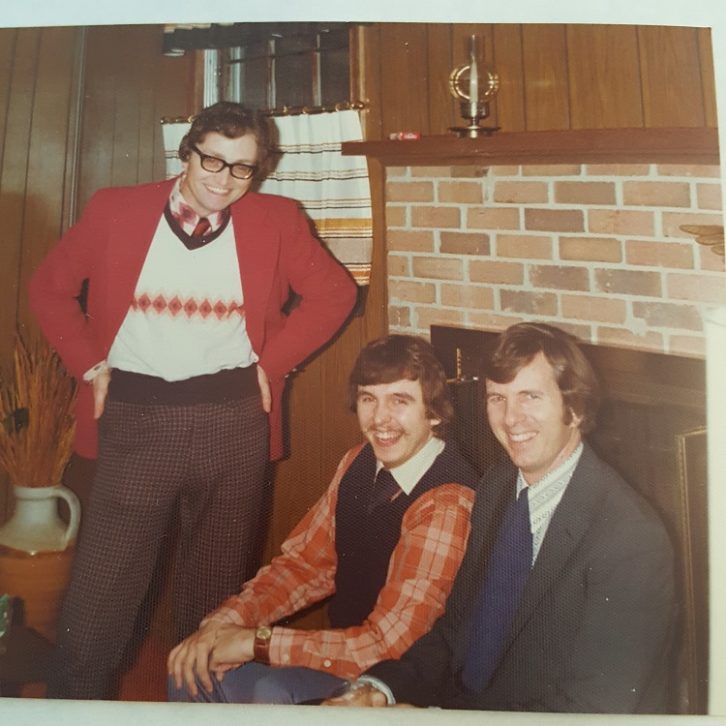

I can’t end without sharing a little-known early career fact about John Bisset that also captures his elfish sense of humor.

“I started out with a parallel career. Intrigued by medicine, I wanted to be a doctor. To help me ace my anatomy classes, I started working as an embalmer and apprentice funeral director.

“My patients never complained!”

Sidebar: Warm Appreciation

Among colleagues and readers I hear warm appreciation for John’s work.

Marty Sacks, EVP of sales, support and marketing at Telos Alliance, has known John for four decades and calls him an industry treasure and trusted colleague. “He’s the same gentleman I have always known. The service he has provided to so many, including me, all these years through his Workbench columns have truly been a labor of love.”

Jim Wood, founder of Inovonics, calls Workbench “a turn-to in each issue; I always come away knowing a little more.” Colleague Ben Barber, president/CEO of Inovonics, saluted John for his expertise in collating and condensing useful information succinctly.

Frank Hertel of Newman-Kees-Hertel RF Measurements & Engineering remembers attending a meet-and-greet with an FCC agent out of Chicago, at which Frank posted a question.

“As it turned out, the FCC agent did not have an answer, but John did! He nicely stepped in and saved the day for the agent. He presented the answer authoritatively, but also with a calmness that radiated a true source of knowledge. After all, John actually was involved in writing the FCC ruling pertaining to low-power toroid RF ammeter readings.”

And Charles “Buc” Fitch — who like John is a past recipient of the SBE Educator of the Year Award — has said that industry knowledge now seems to have a “half life” of about four years, meaning half of what we learn or buy today may be useless in that amount of time.

“So how do we keep up at this aggressive pace?” Buc asks. “How do we learn?”

“We teach each other.”