What kind of engineering-related tools did the recent holidays bring you?

Broadcast engineer Archie Stulc wrote in to emphasize the importance of carrying your own tools and of choosing tools of decent quality. “It’s just so much better to have what you need with you, and to know that what you have will work for the job in front of you,” he said.

This got me thinking about what engineers carry — in one or multiple cases — beyond their usual meters, screwdrivers, nutdrivers, pliers, cutting tools, duct tape and clip leads.

What else is a “must have” in your tool kit? What adaptors, devices or spares do you choose not to live without?

Shoot me a brief email at [email protected]. We’ll cover the suggestions in a future column.

Oh, and what about the bag or tool case itself? What’s your favorite?

You may have met retired radio and television engineer Fred Baumgartner serving as master of ceremonies at a Society of Broadcast Engineers Ennes Workshop. Steve Keeney, one of his favorite general managers, once gave Fred a great Delsey brand briefcase, the type carried by many broadcast engineers in the mid-’80s.

It became a perfect field case for crimp tools, wire strippers and punch tools, as you can see in the first photo. As you look over those contents, you’ll see nothing but history. Fred says every new cable seemed to require a new crimper and dedicated stripper.

Fred’s relics

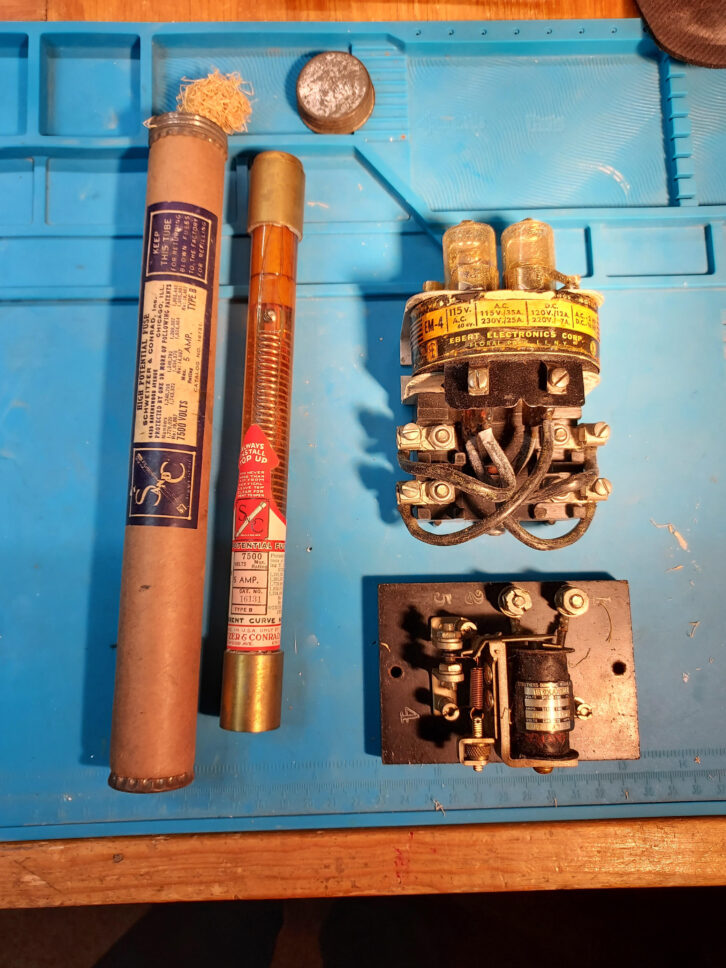

The second photo, also from Fred, shows relics from WIBA’s 5 kW Westinghouse AM transmitter, which was built into three safety-interlocked rooms inside an Art Deco transmitter building. A new RCA replaced the Westinghouse in 1950.

On the left is a B+ fuse that uses a spring in PCB oil to instantly quench an arc when blown, typically when a final tube or capacitor shorted, thus saving the mercury vapor rectifiers, transformers and the like. Note that this fuse can be “refilled.” Sand-filled cartridge fuses do the same job but at lower voltages.

Big relays constantly needed contact “burnishing” or they would corrode, overheat, arc and fail. However, if the contacts were mercury (as with tower flashers, for example) the problem is solved. The mercury is pooled in the glass tubes and the coil, when energized, drives the contacts into the mercury for this double-pole, single-throw “contactor.” Mercury-whetted contacts are the little brother.

In the days before broadcast engineers set current trip limits with a smartphone or a greenie, we adjusted the spring tension and contact placement on the device shown at lower right in the photo, in order to achieve the correct current trip point. This one trips in the 100 mA neighborhood.

Given the maintenance required for transmitters of the 1950s and ’60s, it’s no wonder stations needed a flock of engineers to keep a station on the air.

Are your breakers labeled?

In the Alabama Broadcasters Monday Morning Coffee and Technical Notes e-newsletter, Larry Wilkins shared a great reminder about breaker panel labeling.

Larry conducts a lot of station inspections as a part of the Alternative Broadcast Inspection Program. He finds that many panels have no labels at all.

This is an important safety concern. In an emergency, having a clear breaker label can be the difference between life and death.

If the panels at your studio and transmitter sites are not labeled, or if you’re not sure that the labeling is correct, be aware that Amazon and the big box stores have circuit tracers that will identify breakers without having to turn them off. A Sharpie or similar brand marker will work, though if your handwriting is sloppy, use a label maker. (You can also print small labels to identify the panel and breaker and place these on each electrical outlet.)

Another approach is to print out an electrical panel map from your computer, slide it into a clear plastic sheet protector and tape it inside the breaker box door.

Finally, always replace the breaker cover panel after your work is completed.

If you’d like to receive Larry’s free weekly newsletter, send him an email at [email protected].

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].