The author is president/CEO of Bohn Broadcast Services and The MaxxKonnect Group. This commentary appeared in the free Radio World ebook “Mission-Critical: Maintaining Your Transmitter Site.”

Picture it: 1997.

Bill Clinton is president. Reed Hundt is FCC chairman.

Radio deregulation is now the norm — but so are tube transmitters, analog consoles and dialup-only remote controls.

It was a different world in so many ways.

In 2021 deregulation is still the norm, but solid-state transmitters have overtaken tubes by a large margin. Analog consoles are still in service, but AoIP has a huge stronghold in the modern broadcast plant. And remote controls now can call, text and email.

What’s the common denominator in all of those modern devices?

IP connectivity

We live in a world where the internet is connected to everything from your phone to your security systems and, in some cases, even your refrigerator.

The modern broadcast plant is no different. Today’s solid-state transmitters basically are giant computers with RF amplifiers attached to them. They’ll tell you exactly what the fault is and in some cases even order parts for themselves — as long as they have an internet connection.

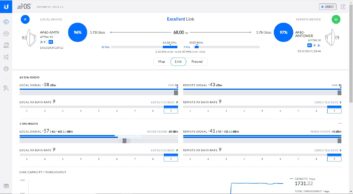

Remote controls allow you to connect nearly infinite amounts of monitoring and controlling countless devices, plus they’ll show you everything visually on a neat little screen — as long as the internet is working.

POTS lines are nearly impossible to get in many locations now, but you want the remote to call you; what’s the solution? A reliable VoIP service is great — if you have internet.

Many broadcasters have embraced the connected site. Cameras, Burk ArcPlus remote controls, Nautel transmitters — you name it. But the key is reliable and redundant IP delivery. There are a plethora of ways to accomplish this.

The earliest P2P IP option specifically for broadcasters was duplexed ISM radios, offered by Moseley as LANLink nearly 20 years ago. This provided a 512 kbps data link from studio to transmitter site and offered Ethernet and RS-232 connectivity.

It was a revolutionary system and allowed, for the first time, networked devices to live at the transmitter site but be part of the studio LAN without adding costly telco circuits or expensive, dedicated, licensed standalone radios.

The IP delivery landscape was altered again with the proliferation of low-cost unlicensed 2.4 GHz and 5.8 GHz radios. These systems, with their significantly higher throughput, altered the way stations delivered content to their sites.

Traditional 950 MHz STL systems were backed up, and in some cases supplanted, by IP-only radios carrying codec audio, HD Radio data, RDS metadata and remote control information.

Now sites without some type of internet connectivity are in the minority.

IP radios have become, by far, the most common method of internet delivery to transmitter sites. Prioritized cellular, such as my company’s MaxxKonnect Wireless offering, is another great option to get connectivity into a site without major tower work, large upfront costs or long-term commitments.

If fiber is available at your site, take advantage of it! Costs on fiber internet are coming down significantly.

Satellite internet is an option as well. In the past, satellite has not always been the fastest or most reliable option. However, with the coming of SpaceX’s Starlink and other new low-earth orbit (LEO) technologies, satellite could rival wireline delivery in the not-too-distant future.

And so?

You may be asking yourself, “What does this have to do with site maintenance?”

Answer: Everything!

Having the ability to know what’s going on at your site, even when you can’t get there as often as you’d like, is key to keeping things running smoothly.

Example: Install an inexpensive web camera or cameras at your site. We typically install three: one looking at the room as a whole, one outside the door, and one aimed squarely at the front of the transmitter and/or equipment racks.

This allows you to know who or what is lurking at your site, inside and out, plus it allows you to diagnose equipment faults or failures visually before rolling out.

Being able to see which fault indicator is lit on an older transmitter or hear the UPS beeping through the camera lets you plan for what tools and equipment to bring on your trip. This is a huge timesaver for an engineer. And less time spent on a problem means less money spent or lost — which is a win for management.

Another example is program delivery redundancy.

IP radio systems are awesome but they’re mounted on a tower and will, most likely, get popped by lightning at some point. Same goes for 950 MHz STLs.

A wireless internet option such as prioritized LTE provides an alternate program delivery path that is less prone to lightning strikes and power spikes. This backup program path can be the difference between minutes of off-air time or hours.

Climate control is another hot topic for internet connectivity. App-linked Wi-Fi thermostats are a great way to give you 24-hour remote control of the temperatures at your site. Set up your own lead/lag controller using the schedule functions, and adjust it from your phone at your house. Plus, you’ll know immediately through push notifications if the temperature exceeds the limits you set.

Other benefits include the ability to look up manuals and parts onsite rather than the 4-inch screen of your phone, and Wi-Fi calling capabilities. At many remote sites, Wi-Fi may be the only way to get a call through if cell service in the building is bad.

Our connected world is overtaking our broadcast facilities. There are more options than ever before to know what is going on at your site, without being there.