This story appeared in the Radio World ebook “Great New RF Installs.”

Faced with the approaching end of life for the tower serving its TV station and radio station, the University of Missouri began plans to erect a fresh one a few hundred yards away.

The tower project, new antennas and new transmitters would ensure that KBIA(FM) and KOMU(TV) would continue to be “a staple of mid-Missouri for decades to come.” But the school didn’t expect the project to take five years.

KBIA is a Class C1 noncom educational with 100 kW effective radiated power serving Columbia on 91.3. Its analog and HD1 channels carry news and information, while classical music is heard on the HD2 and adult contemporary on HD3.

KBIA’s signal radius is about 60 miles. (It also has an FM signal in Mexico, Mo., and feeds a sister station in Kirksville that’s licensed to another university.)

“The station is the area’s largest provider of arts programming,” its website states, “serving more than 30,000 listeners and members each week, and is today one of the few remaining providers of local news.” It has been an NPR member station since going on the air in 1972; it also carries programming from Public Radio International, American Public Media and other national and local sources.

Mizzou claims the title as home to the world’s first school of journalism, which was founded in 1908. Training journalists is part of the radio station’s mission.

The university provided project management support for the overall project, but each media outlet was on its own for funding. KOMU was the primary funder while KBIA created a capital campaign for its portion and is essentially a tenant on the tower, though it was involved in all planning details.

Thanks, Beef Farm!

According to KBIA Chief Engineer Mark Johnson, the KOMU TV newsroom was about 12 feet from the base of the old tower. Even though its roof had been reinforced, the staff occasionally would have to move cars or leave the building for fear of falling ice. And the push for a new tower gained impetus from the 2018 collapse of a tower elsewhere in the state in which a person died.

Chris Swisher is chief engineer of KOMU; he and Johnson worked closely on planning this project. Cavell Mertz & Associates was the technical consultant, with Pillsbury Winthrop Shaw Pittman LLP as the legal representative.

The old FM antenna was a 12-bay ERI fed by a unique HD Radio implementation designed by former chief Roger Karwoski. It employed two Harris Z7.5 transmitters plus a Harris Z16 providing the last 10% of analog plus the digital power.

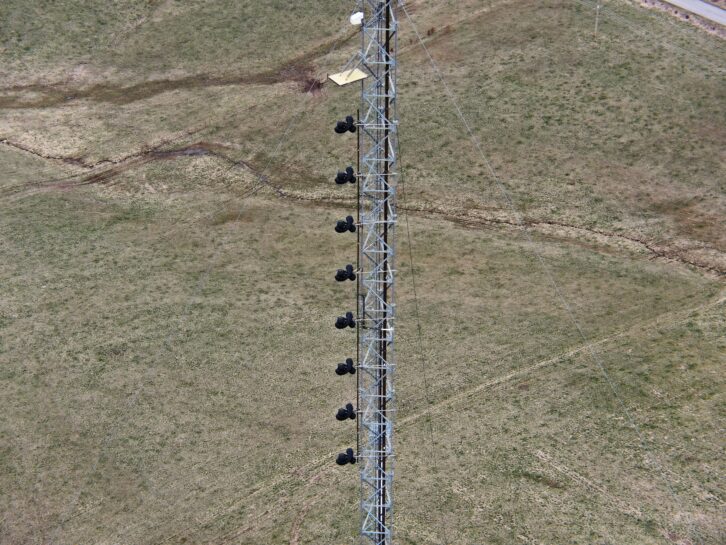

For the new 780-foot tower, the university chose a Stainless model from FDH Infrastructure Services, with two 24-foot-long buildings for the TV and radio transmission gear at its base, provided from Concrete Modular Systems.

Having room to grow was important. “We felt that this could be the last TV or radio tower that we see for a long period of time, so we didn’t want to be in a situation of not having enough space if either station needed additional equipment later.”

The tower is on land managed by the university’s Beef Research and Teaching Farm.

“That was a good collaborative effort because the farm didn’t have fiber and they wanted to upgrade their networking and internet for research projects. They were willing to provide us space in the field as long as we also got them hooked up with fiber.” (This arrangement had a little extra benefit because it turned out that the farm’s managers were willing to loan their equipment for moving heavy objects.)

KBIA now has an eight-bay ERI Rototiller fed via MACX rigid line from a Rohde & Schwarz THR9 transmitter; the latter was installed by Johnson and Fred Francis of Xenirad Broadcast Engineering.

A pair of five-ton Bard air conditioning units cool each transmitter building, but they don’t have to work too hard given that the TV and radio operations both went with liquid-cooled transmitters.

“We have one heat exchanger outside,” Johnson said, “while the TV has seven for their transmitter and dummy load, plus a big old generator. So we definitely feel like the little brother on the tower!”

[Sign Up for Radio World’s SmartBrief Newsletter]

Wait, then hurry up

COVID of course played havoc with many projects over the past four years. Like many engineers, Johnson and Swisher encountered frustrating supply chain delays, particularly for electrical components, which were being prioritized for health care.

For instance, their generator supplier quoted a delivery time of one year. (The engineers eventually switched to a Gillette model.) Then a 400-amp electrical panel was backordered, as were two circuit breaker panels.

“They told us they couldn’t guarantee three months, so they said six. But then six months rolled by, but we couldn’t get any more information,” Johnson said.

“Eventually our Gillette generator came in, then our 400 master panel came in, so we had those ready to go. But we were still waiting on these two subs. KOMU couldn’t operate without that rack power — we needed both subs before we could be energized, but with MDP3 we could at least do our electrical rough-in and setup.

“We kept waiting and checking in each month. We finally were told that our panel hadn’t even gone to engineering yet.”

Johnson said he could understand why electrical supplier Square D didn’t want to make a commitment that it couldn’t keep. “But we couldn’t do any planning. It was a series of ‘hurry up and waits.’”

Finally, KBIA’s electrical contractor suggested using fuse disconnect switches rather than breaker panels.

“And they got them, and then ‘bam, bam,’ they had their electricians out right after Christmas, and they did a bang-up job. They were awesome, everyone was ready to roll,” Johnson said.

“And then a week later my panel came in out of the blue.”

Johnson knows Murphy’s Law can kick in at any time in projects work, but he confesses that he found himself muttering at the panel, “I was waiting for you almost a year, and now you show up and you’re just a lump on the floor.”

In the end the university found another use for that panel. “It didn’t go to waste.”

But time stretched out on all aspects of this project.

KBIA had ordered its transmitter early, anticipating the impact of U.S. tariffs on equipment from Europe. “I bought the Rohde & Schwarz in 2020 and stored it in a climate-controlled area. But because the pad and building weren’t ready, it was still in its box when its original one-year warranty went up.” The ERI antenna and line also were ordered early.

In the end, according to its website, the station saved at least $50,000 because it avoided subsequent price increases that swept through the economy.

Also, Johnson had been attempting since early 2019 to attend an NAB Show to gather information for this and other projects and to work on an SBE certification. He could only roll his eyes when he finally was getting ready to attend the 2022 show, only to be informed that the FM antenna from ERI would be delivered and installed smack in the middle of that convention week.

Thankfully his assistant Tim Raymer was able to cover for him during that installation.

But then the planned antenna height needed to be adjusted by about 20 feet because of a complexity caused by a guy wire configuration issue. At another point, the crew hanging the antenna thought it had only half of the necessary spring hangers, so Johnson asked the factory to ship 35 more, only to find out that there had been a communication error and that the crew didn’t need the extra crate of components after all.

The radio and TV stations are on the air with their new facilities, and the old tower is now disassembled.

Although the various issues caused stress, Johnson said the university staff and its contractors dealt with them well. “No one pointed fingers. Everybody said, ‘Yep, this is a slog, but we’ll get it done.’”

All part of working on a job like this, right?

“I don’t know that anybody would have expected the project management to take five years for this,” Johnson said with a laugh. “In fact my family has added two children since the project began.”