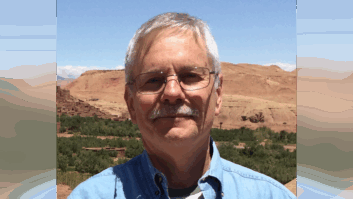

Fig. 1: A typical regulator shows both line pressure and volume. Gary and Cindy Cavell of Cavell, Mertz & Associates, Paul Shulins of Greater Media Boston, Mary Ann Seidler of Tieline and I led a day-long RF “boot camp” aimed at IT engineers at the NAB Show.

This was one of many efforts that the SBE and NAB are taking to help educate IT professionals. More than 60 folks showed up to learn the ins and outs of what happens beyond the studio.

Workshops like this remind us of things we may take for granted. Yes, today’s equipment is much more reliable, but systems still need to be checked periodically.

So if you haven’t scheduled some quality time at your transmitter site in a while, you’re probably overdue. Let’s start with a subject that was of particular interest to the attendees: focusing on FM and nitrogen pressure on the transmission line.

The pressure gauge, as seen in Fig. 1, can help you avoid disasters. This gauge usually is located at the transmission line input. Monitor it for at least three psi (pounds per square inch) pressure on the line. The nitrogen provides dry, positive pressure to the inside of the transmission line to keep moisture out.

While at the site, check the volume of the nitrogen tank. Full tanks have a volume of around 2,200 psi. Log both the pressure and the nitrogen volume; a dropping tank volume will signify a leak in the line. Keep a clipboard with this information right at the tank. Also include the phone number and address of the nitrogen supplier, so you can order replacement tanks easily.

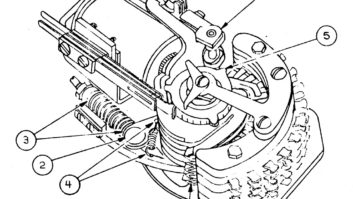

At our boot camp, we discussed tank safety, too, because 2,200 pounds of pressure per square inch is enough to blow a hole through your hand or, if at eye level, blind you … even kill you. Never open a tank without a regulator attached.

Fig. 2: Keep nitrogen tanks capped when not in use. Keep the nozzles of unused tanks covered with their metal screw-on covers, pictured in Fig. 2. Make sure tanks are secured against the wall. Chain or commercial tank supports work best. This is an OSHA requirement. You can find the tank supports online or at a local welding supply shop.

A fire marshal once told me about an unsecured tank that fell. The valve assembly broke off and the tank tuned into a missile, blasting through two cinder block walls and landing out in a field. You can’t be too careful around nitrogen tanks!

If the transmission line is not pressurized and moisture develops inside, VSWR (reflected power) can increase. If the condition is ignored, a costly flashover inside the line can be the result. This usually results in line replacement, as seen in Fig. 3. The situation is not only costly but keeps you off the air until it is repaired.

Some stations may use unpressurized rigid copper line sections of transmission line inside the building. Since the outer conductor is at ground potential, use your hand to feel for any hot spots along the line. Ninety-degree elbows may be warm, but should not be hot. A hot elbow could be the result of a bad connection or split bullet. Remember, heat will eventually destroy components, so don’t ignore this type of warning.

Here’s a good question from one participant, “What do I do if the line pressure is falling?”

First grab a bottle of Formula 409 or Fantastic spray cleaner. With the tank valve and regulator on, spritz the soapy cleaner around the regulator fittings, then along the hose leading up to the transmission line, and finally at the gas inlet port on the transmission line itself. If there is a leak, hundreds of tiny bubbles will appear as the gas escapes.

There’s your leak — and you didn’t have to call in a tower crew.

Fig. 3: The line at left is contaminated by soot. Tell this to the manager. Let him or her know when you save the station money through preventive maintenance. Usually, tightening the fitting or replacing the hose will solve the problem.

If you don’t find any leaks leading up to the transmission line, calling in a tower crew may be necessary. They’ll inspect the line all the way up to the antenna, checking all fittings just like you did but also looking for bullet holes or other damage to the transmission line.

Some stations may use a dehydrator instead of, or in addition to, nitrogen tanks. Two things to check on these devices: First, do they seem to be running all the time? Even twice an hour is too much. More typical is once every hour or two. More activity could indicate a leak.

The second thing to check is that the moisture-absorbing crystals are blue. These crystals turn pink when they absorb moisture. Check with your manufacturer about replacement. Moisture-laden crystals can be rejuvenated in a warm oven, so don’t throw them away.

More transmitter site maintenance tips next time.

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips to [email protected]. Fax to (603) 472-4944.

Author John Bisset has spent 44 years in the broadcasting industry and is still learning. He handles West Coast sales for the Telos Alliance. He is SBE certified and is a past recipient of the SBE’s Educator of the Year Award.