John Andrews worked for WTAG(AM), Worcester, Mass., from 1970 through 1996. In the early 1970s, the station’s main transmitter was an RCA BTA 5-H, installed in 1959.

One day, the RCA went off the air and would not respond to overload resets via remote control. With the station itself still comfortably broadcasting with a 250-watt backup transmitter and antenna at the studio, John went to the transmitter site and found that the neutralizing transformer for the 5762 PA finals had arced and burned.

Now, with an RCA 5-D-1 auxiliary transmitter on the air at full power, John could take time with the repair. But the cost of a transformer replacement from RCA was just shy of the GNP of many nations, so John and his boss decided to repair the existing part.

Their inspection disclosed damage to the Teflon rib as well as burnt insulation on one of the windings.

Using a handsaw and some scrap Teflon, they replaced the rib and rewound the burnt section of the winding. With some trepidation, they reinstalled the repaired transformer and applied power. All worked fine, and the rig was put back on the air that night.

John’s boss was not satisfied, though; he felt they should have a replacement transformer.

The first photo shows the result. Over a week or more, they located a 6-inch length of 4-inch phenolic tube, and cut eight ribs from some very old maple. To combat moisture, John’s boss boiled the maple ribs in beeswax. Then they wound the transformer using some 22-gauge double-cotton-covered wire they had on hand.

They laid the first winding down directly on the form, and then lacquered it. They used brass hardware to assemble the ribs onto the form, and added the other windings. Then they lacquered the whole thing and, just to be safe, hi-pot tested it.

During a rig maintenance session in the following days, they installed this homebrew replacement. It worked identically to the original.

John reinstalled the original transformer and put the “new” one in a cabinet.

The RCA 5-H eventually became an auxiliary transmitter, serving into the early 2000s. When John came across the homemade spare, he couldn’t throw it out. Today it sits on a shelf, right above his ham rig.

If John’s name sounds familiar, you may have encountered him in his days at Comrex. He now is retired.

We have a match

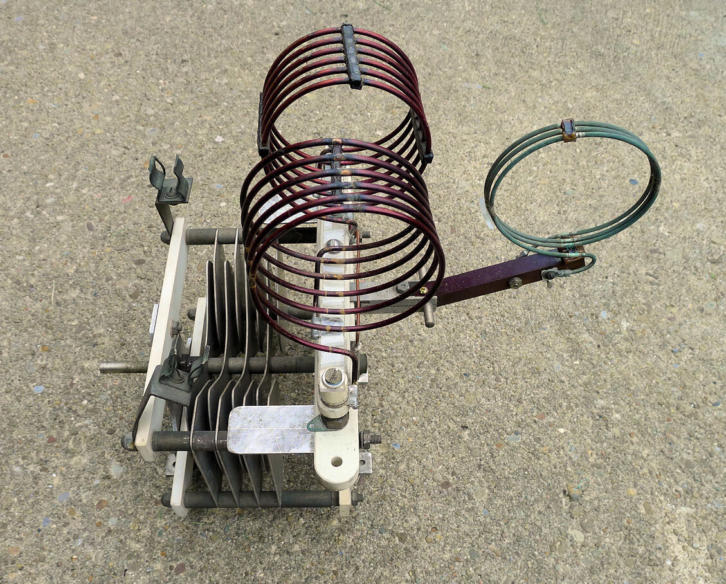

In a recent issue we showed an interesting picture of what many hams have identified as a Barker & Williamson link-coupled matching network.

Rob Atkinson, K5UJ, was one of many who wrote that the components were used as the output network for a push-pull Class C RF power amplifier. The PA is loaded by moving the swing link jack bar in and out of the center of the coil. The balanced feedline attaches to each end of the swing link coil.

Back in the 1930s, Rob writes, ham bands were changed by swapping plug-in coils (only when the rig was powered down, of course). Some hams pulled arcs from the coils using screwdrivers as a way of showing off. If you pulled the longest arc in town, you had the most powerful rig.

What happened to these rigs? Television!

TV interference forced hams to adopt new designs with lots of shielding, necessitating band-switching from safer front-panel controls.

Rob has been working on resuscitating a 1949 Eldico TR1. Shown in our third photo, it consists of a single 813 modulated by 811As. The power supply employs two 866A mercury vapor rectifiers.

This rig consisted of two chassis: the RF and audio chassis (shown), and the power supply. It was sold in kit form and was intended to run with the open chassis sitting on a tabletop with the power supply and AF/RF (audio frequency/radio frequency) chassis side by side, out in the open (with 1500 volts exposed!). Rob got a laugh when he discovered a “UL approved” sticker on his unit.

Thanks to all who responded.

[Read more Workbench columns.]

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].