Wayne Eckert is with the Rural Florida Communications Cooperative and a frequent Workbench contributor. He notices that a lot of electronics are using terminal blocks now.

He finds them to be decent connectors, usually rated for AWG 24 to AWG 14 at up to 15 Amps, but says they’re prone to overheating and melting, often because the screws were not torqued properly.

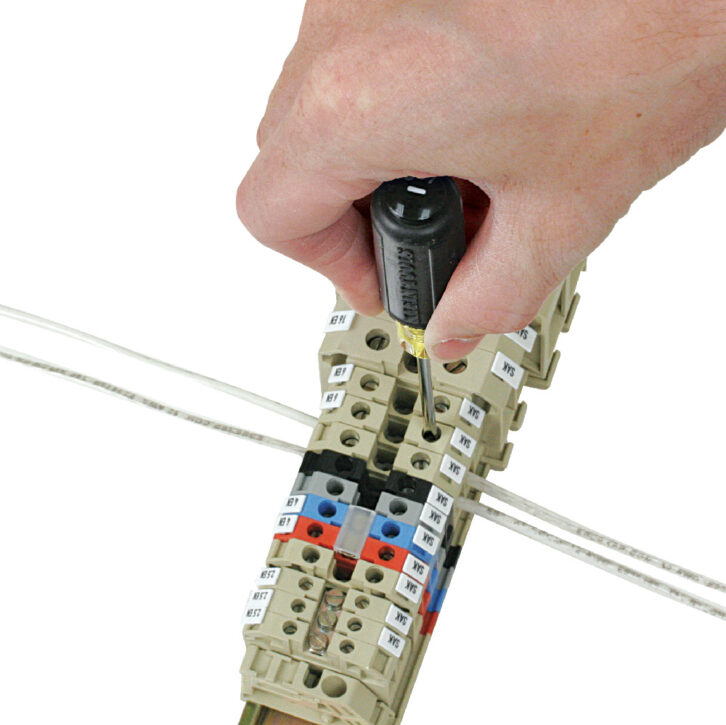

These terminals require a screwdriver with a 1/8-inch blade, but many people use a jeweler’s screwdriver or other tool that doesn’t achieve the proper fit.

As usual, the tool for any job is out there, and Wayne learned that Klein Tools offers a screwdriver for this application. It costs about $9 and is well worth buying for your toolbox or pouch.

The full proper name is “Klein Terminal Block Screwdriver, 1/8-Inch Cabinet, TB-DIN,” and the Klein part number is 612-4. It has a medium-sized rubber-sleeved handle that will deliver plenty of torque to tighten DIN connectors, with an exact fit. The butt of the handle is labeled “TB-DIN” so you can find it easily in your bag. And the screwdriver is made in the USA.

Archie pays homage

Retired broadcast engineer Archie Stulc admired the pictures we published of Dave Morgan’s master parts depot. Archie joked that if he were found worthy, he would enter that holy site and pay due homage.

Dave’s organizational process may in fact seem over the top, but what a pleasure to work with the results. And the project didn’t happen in just a few days; it took weeks to plan and months to get everything organized. Dave adds that he’s still not finished.

The key to organizing as Dave did is to start small and build on what you can, when you can. The effort does pay dividends in knowing what spares you have on hand.

Cue the hydraulics

Chris Wilk is the transmitter engineer for Draper Broadcasting in Salisbury, Md. He and his team faced a common decision: Should we build our new studio for seated or standing operators? If standing, how do we accommodate the range of heights of our air staff or an operator who uses a wheelchair?

Custom cabinet shops can build you a counter that will accommodate both modes of operation using hydraulics, but Chris found a retrofit kit from Ergosource in Minnesota that costs about $1,500.

The lifting is performed by four hydraulic “legs” affixed to the cabinet. A local cabinet maker helped them attach the hydraulic mechanism onto the furniture; then Chris mounted an up/down switch in a rack panel to allow each operator to select the best height.

At www.ergosource.com scroll down to Hydraulic Lift Systems.

If you take this approach, Chris reminds you to provide an extended cable harness for the table-top equipment with enough loop to allow the counter to be raised and lowered.

The kit comes in six different adjustment ranges from 6 to 16 inches. There are also hand-crank versions and kits for tables with fewer legs.

Rick’s Command performance

Rick Foster has been behind the mic for more than 60 years, and although he’s mostly retired, he still hosts a show on a community station on Saturday afternoons.

Rick, who has used a lot of headphones, saw William Harrison’s tip in January about installing a hook on a broadcast rack. Rick has found an inexpensive and secure “hanger” of his own, a hook in the Command brand line from 3M. You can stick it on the underside of the table that holds the mic or the console. Rick says he affixed a hook in his home studio 10 years ago and it’s still in place.

You and Workbench are a perfect fit. That’s why we want your tips! Email [email protected].