Rolf Taylor is with Rocket Engineering and Consulting in northern Virginia. He read about the lock problems we discussed here in February.

Rolf divides lock issues into cylinder problems, latch problems (doorknob or deadbolt) and lockset problems involving the mechanism inside the door.

If the latch or bolt is binding, fix that first. Friction here is a cause of frustration and broken keys. Lubricating the cylinder won’t help. Often it’s a matter of aligning or filing the strike plate on the door frame, as shown in Fig. 1.

Note that when you fix hinge problems (like loose screws causing the hinge or door to sag), you can cause misalignment issues.

A little bit of very light lubrication on a bolt or latch is OK (wax is a good option) but won’t solve most problems.

For deadbolts, see if the door is hard to lock/unlock using the twist knob inside the door instead of the key outside. If it is hard to operate, alignment is likely your problem.

With doorknobs, lifting up while turning the knob can give insight into hinge problems. Viewing the alignment of the latch as it meets the strike plate can also be useful.

For the lockset, binding is often indicative of long-term wear. Still, disassembly and lubrication is worth trying. For old-timers, this is similar to lubricating the various parts of an automatic record changer.

If the old grease is stiff, you will need to clean it off. If it’s in good shape it may just need to be redistributed to the right areas and perhaps rejuvenated with some oil mixed in.

Rolf generally recommends a very light grease, like the tubes of white grease sold for lubricating car door hinges. Often he will mix this grease with a bit of light oil such as 3-In-One to obtain a more liquid suspension, which is easier to distribute.

(According to 3inone.com, their product’s roots go all the way back to 1894, when George W. Cole of Asbury Park, N.J., compounded a mixture to accomplish three things in connection with the maintenance of a bicycle: a lubricant, a rust preventive and a cleaner.)

For the actual lock cylinders — the part where the key goes — first suspect the key. Copies of a key may be marginal and thus not work consistently. Lubricating the cylinder may help, but it’s better to replace the marginal key with a fresh copy made from a key that works properly. If you have a key with a six- or eight-digit number code on it, that is an original.

If the only key you have is badly worn, you can ask a locksmith to “originate” a key from the code. This should give you a perfect copy made to the original specs. If the cylinder is difficult to turn using multiple keys, lubrication is worthwhile.

Lock-Ease Graphite Lubricant by AGS is an aerosol, similar to KANO’s Penephite graphited penetrating oil. It is readily available at hardware stores but less expensive than the KANO product. You could try that if the 3-In-One doesn’t do the job.

[Read more about fixing a common door problem.]

Lock and lube

Continuing our ongoing discussion of lubricants and related products:

Alan Colwell is an SBE Life Certified Professional Broadcast Engineer. He is a fan of LPS No. 1 Greaseless Lubricant, sold by hardware and industrial supply stores as well as Amazon. He was introduced to this product nearly 50 years ago by his local electronics dealer.

Since then, Alan has used LPS-1 to keep all of his locks working. He prefers it over the popular WD-40 brand, which costs less but that he finds hard on plastics. When he worked for a local radio and TV repair shop, they would clean noisy volume controls with tuner cleaner; they tried WD-40 on plastic volume controls, but it melted them, while LPS-1 did not.

Free is good

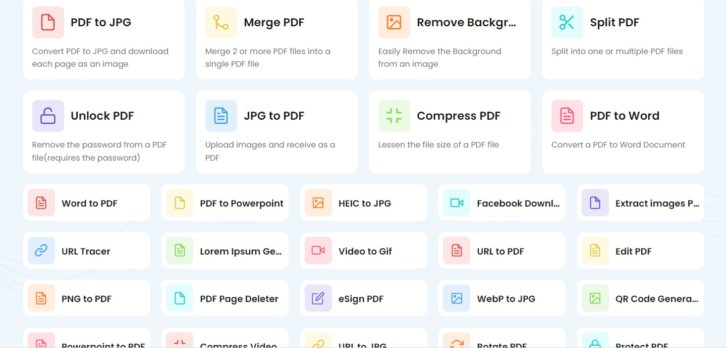

Dan Slentz discovered a really neat site that can help engineers manipulate their files. TinyWow.com is a collection of online tools that perform tasks such as editing PDFs, converting a PDF to a JPEG image, compressing or re-sizing video, adding text to an image or converting a PDF to a Word document.

“TinyWow is free. We don’t have ads, we don’t sell data,” the site states proudly.

“We currently have no plans to monetize. Why offer these tools for free? We operate two tech websites: Alphr & TechJunkie. We thought our users might find these tools helpful. For now, utilizing our existing infrastructure we are able to operate these tools at minimal additional cost. Building this and watching the growth has been fun, so we’re going to keep building free stuff.”

They add that when you upload a file to their servers for processing, they delete the file 15 minutes after the processing is complete.

GWB for your XLR

Oh, and here’s a trick Rolf Taylor learned to keep XLR pins wired properly: “George Washington Bridge.”

1 = Ground (George)

2 = White (Washington)

3 = Black (Bridge)

But Rolf adds that when he learned this, most microphone cable had white and black for signal conductors. Because most cabling today substitutes “red” for the Pin 2 “white” connection, you’ll have to rework the phrase! Suggestions?

John Bisset, CPBE, has more than 50 years in broadcasting and is in his 32nd year writing Workbench. He handles western U.S. radio sales for Telos Alliance and is a past recipient of the SBE’s Educator of the Year Award.

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].