That big orange, green or gray box sitting outside your transmitter building is easy to forget. It just works — as long as it’s maintained.

Money spent on a contract with a local generator service company is well spent. However, budgets being what they are, such service may be one of the first expenses cut by management.

Here are maintenance tasks that you can perform to help keep your generator in reliable operation. Like a car, your generator needs routine maintenance if it is to perform reliably. A good rule of thumb is to inspect it quarterly. Pair it with your quarterly tower inspection.

If your generator has been in service in an emergency, also inspect it after every 150 hours of operation. If it has been running, it’s also helpful to know the fuel consumption. One of the most embarrassing things to explain to management is that your generator kept your station on the air but then stopped because it ran out of fuel.

Identify several sources of fuel now — don’t wait for an emergency. Meet with these providers. Take them some station T-shirts or other swag. Develop a relationship with them; swap emergency contact names and cell numbers. Write it all down and post it at both the transmitter site and at the studio. Give the information to the station general manager and operations manager too. The goal here is to avoid surprises.

If your generator is powered by diesel fuel, purchase a container clearly marked for diesel fuel, as pictured in Fig. 1.

So what should I check?

Before you get inside, scrutinize the outside of the unit. Are there hole plugs missing, as seen in Fig. 2? If so, fill them with wads of stainless steel wool, which doesn’t rust, until you can obtain replacement hole plugs.

Vegetation on a generator can restrict air flow and attract vermin, including snakes. Remove growth from around or atop the unit. Consider creating a perimeter of crushed stone atop a fabric weed barrier.

After inspecting the exterior, disable the generator at the control panel and throw the breaker. You don’t want it to start while you are doing your tests and inspections.

Look inside with a bright light, searching for leaks. Check fluid levels including oil, fuel and coolant, and add them as needed.

Wipe down the bottom of the generator — a clean interior will help you identify problems over time.

Observe the exhaust system — no restrictions, right? Look to make sure there are no holes in the exhaust pipe.

Speaking of restrictions, check that there are none in the ventilation system. Leaves and nests can cause blockages. If you live in cottonwood country, the air is filled with fluffy cottonwood seeds from March to June. Those seeds are drawn to the air intakes on generators, air conditioners and fan systems.

Consider installing hardware cloth over the ventilation intake point of the generator. The cloth won’t keep the bees out but it will discourage mice and lizards.

Wipe down the battery cables and inspect the connections for a tight fit on the terminals (Fig. 4). Remember that the generator is run by a motor that vibrates, which can loosen connections. Make note of when the battery was replaced and the type. Lead-acid batteries, the most commonly used, last about three years. Absorbent glass mat (AGM) batteries can run up to four to five years. Lithium-Ion batteries can last up to seven.

Your battery life may vary, but if you have a six-year-old lead-acid battery, you probably are running on borrowed time.

After checking the coolant level, wipe down the coolant hoses. Check for bulges, which indicate weakness. Then squeeze the coolant hoses with your thumb and forefinger, looking for cracks or brittleness in the rubber; these are a precursor to failure.

Rubber hoses have a lifespan of five to 10 years, but high heat degrades rubber. According to AutoZone, higher-quality rubber hoses are worth the expense.

While you’re inside the enclosure, check all the control wiring and their connections. This includes wiring to the alternator. Again, make sure connections are secure.

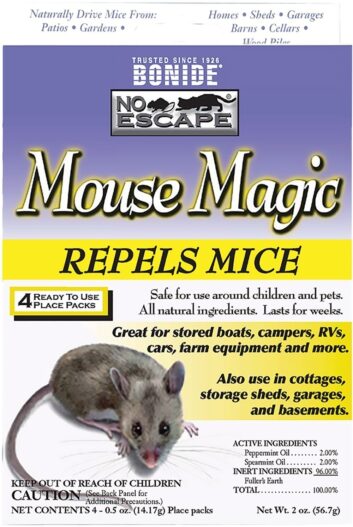

The most common problem here is mice chewing on wire assemblies. In addition to sealing entry points, consider adding a pouch or two of Bonide Mouse Magic, which is found in most hardware stores and available online. These little pouches of essential oils are pleasantly fragrant to humans and are great to discourage mice and snakes. They also work well in a transmitter building and the base of an antenna tuning unit.

Once a year, replace the spark plugs and air filter.

As you wrap up the maintenance, operate the generator. Check the automatic changeover and that the circuit breaker is on. At the end of your test, look again for leaks as well as any alarms on the control panel.

Knowing that your generator is in good shape and ready to run brings peace of mind. Do you have tips on maintaining generators? Send them to me at [email protected].

Workbench submissions are encouraged and qualify for SBE recertification credit. Email [email protected].