Just glancing around your stations you’ll see dozens of applications for concrete. If you never have to use concrete in your work as a radio engineer, you’re on an unusual career path.

A standard engineering school one-liner is that engineers build monuments to their errors. No error is more permanent than concrete work gone wrong. Some problems can be avoided by keeping the following design and installation considerations in mind when planning.

Remember our own standing adage: If you fail to plan, you plan to fail.

How much

Begin by making certain that you know the total volume of concrete that you’ll need.

We all hate waste, but since concrete does not “splice” very well, you should make all complete “pours” in a single session. Having 110% of the volume needed almost assures that you’ll have enough. For a nice touch, use any excess for step pads in front of doors or aprons for trash cans at the street. Forms for these require little excavation and can be made out of scrap 50 mm × 100 mm timber.

A 25 kilogram bag of premixed concrete makes about 0.07 cubic meters of volume. Volumetrically this is not very much, about 410 millimeters on a cube edge. This is about the limit of what you would want to mix up by hand in a bucket or pan. Probably the extent of the work you want to do with this is to place concrete around a fencepost or possibly mix two or three in succession for a small satellite pole. (See our Milestone article about satellites for other suggestions about sat poles.)

On a single project, once you get beyond a few 25 kilogram bags of concrete, you’ll want to mix this volume in a powered concrete mixer. By the way, “cement truck” or “cement mixer” is a misnomer; the vehicle is more properly described as a concrete truck or mixer. The “classic” portable mixer that you would acquire for any project from the rental tool company has a single-batch volume of about 1/4 of a cubic meter.

A cubic meter of concrete ready to pour weighs nearly 2.3 metric tons, depending on the proportions of water, aggregate, cement and additives. You’ll want to make certain that the mixer is well supported so it doesn’t sink into the ground — or worse, tip over at an inopportune moment.

Not to be too pragmatic, but a 1/4 cubic meter load requires about 3.5 bags of concrete of 25 kilograms each. Make certain that the delivery truck places those bags as close to the mixer — and the mixer as close to the pour — as possible.

Also, do not forget that it takes about 48 liters of water for that 1/4 cubic meter as well, so bring the hose right up to the mixer or you’ll be carrying buckets for a while.

Ready-mix

Once you get beyond the practical limits of mixing concrete rigorously by hand, “ready mix” concrete becomes cost-effective. This gray mud is the bounteous stuff that the concrete truck delivers to your door. For a large pour of say 3 yards or more, the ready mix company sells you three features:

- • Professional-grade concrete in plain vanilla or whatever special mix you want;

- • Delivery to your job site and usually directly into the pour;

- • Waiting time, which is the time they allot for being on your site so that if the pour is intricate — such as a long line of fence posts or multiple building piers — you have the truck and the chutes for as long as needed. Usually that waiting time is an allotment of 10 minutes per purchased meter, although this may well vary by region and company.

If you have a small, optional project, a cost-effective alternative even for the customary minimum order of a cubic yard is to buy “odd yards,” left over from someone else’s pour nearby. Remember they also ordered 110%, and on major projects that 10% can total nearly a complete truck load. If you can accept the concrete on short notice, the price is usually half or less than what you would pay if you ordered for a specific time. Be careful though that when this concrete gets to you it is not too stiff (beginning to dry), as it will not set up properly or to strength. Have the driver bring some of the concrete out to you; if it feels stiff or dry (beginning to be gritty), do not accept it.

On any delivery, if the truck takes longer than was predicted or calculated getting to you from the yard, add about 2.25 liters of water per cubic meter and have the driver spin up the concrete for 30 seconds at max speed to freshen it up and homogenize it before pouring.

The pour

On important pours, an on-site test is used called the “slump test,” where a standard conical form is filled with concrete. This standard height “pyramid” of concrete is allowed to “slump” or lose shape downward a calculable distance. Too low and probably there is too much water; if it remains too high, the mix is off in some component.

On a shopping center project in which I was involved years ago, every concrete truck arriving on site had a slump test run and then was dispatched to the next pour site if the concrete passed the test.

Like many technical aspects of radio that have a “sweet spot,” concrete is no different. Temperature has a great effect on curing and it is best never to pour below freezing or above 35 degrees Celsius.

Hoover Dam and its related structures contain about 3.3 million cubic meters of concrete, enough to build a monument 30 meters square and 4 kilometers high or to pave a road nearly 5 meters wide from San Francisco to New York. Credit: Bureau of Reclamation In marginally freezing temperatures, quite often you can use the heat of hydration from the curing concrete to prevent the water in the mix from freezing. Once I had to pour building piers in wicked cold weather and I wrapped the exposed piers after the pour, using moving blankets as insulation. The heat from hydration was kept inside and brought the concrete temperature above freezing.

If you must pour in high heat, evenly and continuously mist the exposed surfaces of the pour with water in temperatures when the ambient temperature is near 38 degrees Celsius. This light water bath will prevent evaporation of water near the exposed surface in the pour. Unchecked evaporation in these circumstances will produce brittle and flakey surfaces that will deteriorate quickly.

Once you start pouring from the truck, do not rush the pour, accelerate the flow or let the concrete splash into the form(s). All of the aforementioned make the concrete components separate, reducing the strength and durability of the final set.

If the pour is over a third of a meter deep, an agitating vibrator will have to be used periodically to remove any air pockets and to homogenize the mix once again. The usual procedure is to pour a layer about 150 millimeters deep and vibrate, and then repeat at similar 150 millimeter intervals. The use of this machine is an art so do not make your first exposure to this device be on an important pour.

Concrete is strongest in compression; the larger the pour, the more tension loads begin to appear. Rebar is added to the concrete structure to provide tension strength complimental to the compression strength of the concrete. Usually rebar is not positioned any closer than 150 millimeters from the edge of the concrete. This is to provide coverage from the elements such as humidity, and freedom from fast changes in temperature that could cause expansion and contraction of the rebar progressively breaking up the concrete. Always use specification-grade rebar in size, pattern and spacing that satisfies the load calculations. Typically the rebar spec would be a yield strength of 500 N/mm2, deformed and sized per the application.

Other considerations

In heavy, demanding situations such as a large generator sitting on a slab, the pedestrian-ready mix or bag concrete might not have enough load-bearing strength and will actually begin to crack and break up from the loads sitting on it. The typical concrete is 14,500 to 29,000 kilograms per square meter. One can easily reach a concern point with this strength if a large load is only supported at a few points.

Higher strengths are available but they must be specially ordered and normally require special attention during installation.

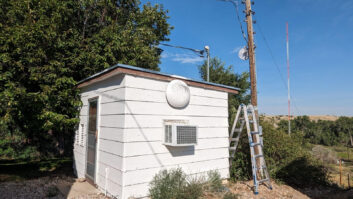

Some examples of loads supported at just a few points are buildings or devices on piers such as your tower base or transmitter container. Quite often these piers are poured with “sono-tubes,” round tubes made of heavy-walled cardboard and covered in wax paper, cut to length so that the pour below grade gets under the frost line or is at least stiff enough to keep the tube from going out of vertical with an overrun above ground suitable for the situation.

Here in the northeastern United States, tower base piers are about a meter above grade to keep the steel or base insulator from sitting in all but the worst snow pack.

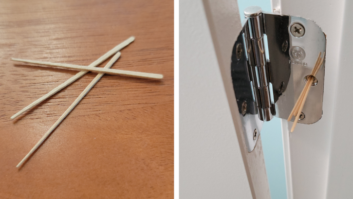

If you look carefully at the caveats inscribed on the side of the tube, there is a maximum height above grade for which the tube is appropriate for holding concrete unsupported before drying. Heed this warning well or make certain that the tube is supported while drying. The wetness of the concrete will make the walls somewhat plastic and the notable weight of the concrete will cause the tube to distend if the height overrun is too great. For a sono-tube that is 150 millimeters in diameter, that unsupported vertical maximum is about 1 meter.

To achieve a flat smooth finish at the tops of tubes or foundation pours, a procedure called “creaming” is used in which the cement in the mix is brought out to the top and troweled into a smooth seamless finish. A refinement to this is to bevel down a finish to facilitate the run off to the edge of any rain or moisture that would gather on the surface. Gravity is our friend in this case and the slight downhill path moves water off and away from the structure.

Concrete is a lot like the enamel on your teeth. You don’t let the enamel on the wearing surfaces of your teeth get chipped or bothered by cavities. Similarly, whenever a crack or chip shows up in concrete, you should repair it with mortar or caulk ASAP.

A great wear preventative once the concrete is fully dry is a protective coating such as Rust-Oleum concrete coat or one of the many epoxy coverings especially useful to prevent damage from standing water.

Concrete is the premier building product. Matters have not changed since the caveman. When a rock will do, you can use concrete.

Related:

“When in Doubt, Use Concrete” (November 2009)