Sing along now to the tune of “Smoke Gets in Your Eyes”:

Dust gets in your eyes, it must be concrete, add some water, watch the flies …

Dust gets in your eyes, we’ll need rebar, mix and pour to your delight

Dust gets in your eyes …

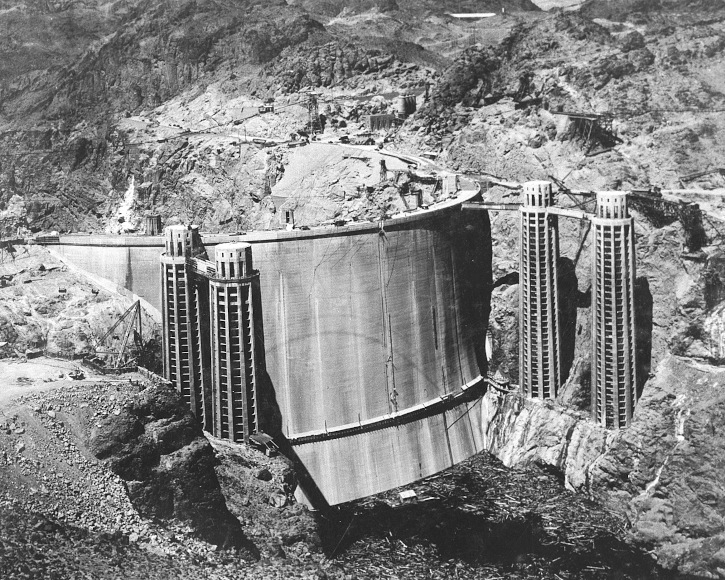

As you know, many structural elements like wire rope (the usual tower guy cable) only have strength in tension. Concrete has an opposite characteristic. It has its greatest strength in compression.

The general formula for concrete is, by volume, one part cement, two parts sand and three parts aggregate (selected small rocks of varying sizes). Water is added to these dry components to facilitate a homogenous mixing and to activate the adhesive quality of the cement. Modern cement actually is a smooth mortar made of a pasty, hydrate lime.

Cement and related concrete formulations have had two great historic periods of use, ancient Rome around the time of Christ and after about 1750 through the present.

In the ancient world most professions were essentially “technique” trades. The relatively limited knowledge on a subject (normally practical, normally useful) would be transferred in a disciplined fashion as one would progress over a lifetime from neophyte/intern/apprentice through journeyman and finally to master. The most important, critical information would only be given to you in secret on your assent to being a master. Sort of like Jedi Knight training.

In ancient Rome, architects (the word comes from “master builder”) looked to the professions of stonecutting, masonry, etc. to build the great roads, viaducts and buildings of that glorious time.

History perceives that the masonry masters around 150 A.D. too closely guarded the formula for cement and that it was “lost” for general use thereafter. The last great building of that Roman period was Hadrian’s Villa, which had a notable cement (with some additives) roof span. After that, cement seems to have been lost through the ages.

That is, until modern times, when by accident, the baking of limestone to make a mortar paste was stumbled upon in England. When water was added to this “new” brew, hydrolization would occur, resulting in a hard solid with adhesive qualities.

Hydrolization is that wonderful ionic action in which the cement, when wetted, bonds together the various elements of concrete — sand, aggregate, etc. — making artificial rock.

[Read: Tips for Working With Concrete]

Most modern cement is of the Portland variety, developed in 1824 by Joseph Aspdin of England who burned fine caulk with finely divided clay in a lime kiln until the carbon dioxide was driven off. The sintered result was ground further until one had the very fine powder that you see in the cement bag you buy at Home Depot or Ace Hardware Store.

The distinguished Mr. Aspdin gave his invention its name, Portland, because he though the color looked a lot like the rocks of the Portland Cliffs in England. These cliffs look nothing like the white cliffs of Dover.

Problem Spots

Successful concrete work is divided into two important parts: preparing the concrete mix, and applying it. Great concrete can be all but wasted if installed improperly.

The two biggest errors are allowing the components of the mix to become separated and/or too dry or wet, and allowing air pockets and/or voids to be left in the final pour.

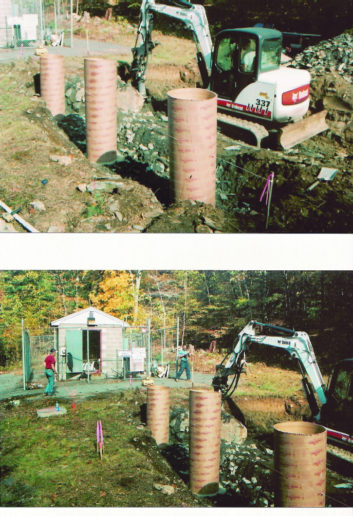

These circumstances can cause a severe reduction in the strength and longevity of the concrete, if not to cause the structure (think the anchors of your tower) to fail.

We mentioned that concrete on its own has little strength in tension so how does one achieve strength in both compression and tension? By reinforcement.

The same way that many have taken credit for wire rope, many lay claim to the premier use of reinforcement in concrete. One of the first quotable instances was by Joseph Monier of France. He reinforced William Wand’s flower pots with wire, ushering in the idea of iron reinforcing bars known now in the vernacular as rebar.

Shortly thereafter Gustave Eiffel started using rebar in the footings for his Paris tower, stimulating contemporaries to make reinforcement rigor du jure. Eiffel also pioneered the mathematical analysis of concrete and steel structures as well about the turn of the last century.

Today rebar normally is deformed steel with its size, type, connection(s) and placement specified by the design engineer. When concrete is used for floor decking and similar applications, fiberglass rebar resembling cut grass is often used in the mix to stiffen the final deck yet providing sufficient flex to ensure little deterioration.

Over these intervening hundred years, concrete technology has matured and we have a gamut of techniques including exotic admixtures (additional components that change the character of the concrete such as faster drying, better yield strengths, etc.).

Admixtures have been with us from the appearance of cement and concrete. The Romans added animal fat, milk and blood as admixtures to add color, hardening, increase durability, etc.

Shrinkage also is a problem with concrete as there is a reduction in volume when it dries. A modern solution is to use epoxy as part of the mix. In Roman times they used horsehair to reduce this problem.

Special mixtures of concrete can be pumped to elevations above 10 floors from the street. The ability to pump concrete is helpful especially when you have to pour anchors across several hundred feet of swampy transmitter site.

One wonderful aspect of concrete worth noting is that it will dry under water if the install is executed properly. This quality is appreciated when installing bases and anchors in that swampy site.

One of my first professors pointed out that the least expensive building material by strength, durability, diversity of application, plasticity in form, coverage, etc. was concrete. When in doubt, when you can and especially when money is tight: Use concrete.

He also pointed out the least expensive building material for exterior coverage was roof shingles. But that’s another story.