One thing I rarely hear engineers at small facilities talk about is documentation.

Managers of large facilities live on their documentation systems. At smaller plants, though, some engineers seem to think they can protect their job security by withholding documentation. And some complain that creating documentation is a waste of time.

They are wrong.

Good documentation allows the staff of a facility to resolve issues in an expedited manner.

What do I mean by documentation?

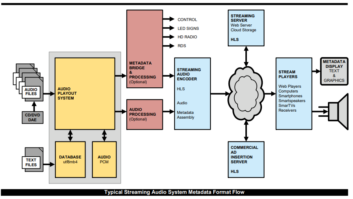

Most engineers will use a good computer-aided design program such as AutoCAD or WireCAD. Yes, a good one will be expensive. Look at it as an insurance policy.

Some use capable diagramming software such as Visio or Simple Wires. Their files can serve as a schematic to your facility, showing equipment, wire numbers, racks and rooms.

They can illustrate signal flow and document the workflow. You can obtain libraries of equipment that highlight all the connections. Sometimes the libraries are available from the product support pages or sold by third parties.

Knowing “which” cable in a large bundle is terminated “where” is valuable. Knowing which connector and pins is indispensable!

In today’s IP-centric world, most cables are Category-5 or Cat-6, terminated with RJ-45s. But then you need to know if it is required to be STP (shielded) or UTP (unshielded). Note this in the documentation.

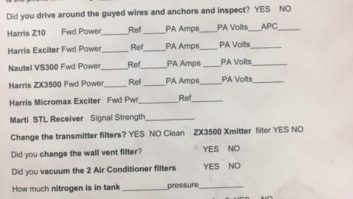

I like to make notes of anything relevant to the safe and convenient operation of equipment. For example a device may need space above and below it for air flow. You or another person will appreciate such details when an emergency repair becomes necessary at an inconvenient time.

The schematics also allow you to plan an upgrade or an equipment replacement. Rack space is a commodity; planning your signal flow with smart equipment placement and the shortest cable runs will lead to a more efficient plant.

Withholding documentation is unwise and could be considered negligent. If you have to put out false traps to demonstrate that you are needed, perhaps you are not.

Good documentation systems allow engineers to take time off. Also, you can manage the inventory. For instance I like to include serial numbers in my notes.

You don’t have diagramming skills? This is understandable. Then just use a good spreadsheet.

Maintain current backups of your documents, too. I usually make one before any change so I can always revert to the last “good” state if necessary. Having a bunch of printouts with pencil scratch-outs is no substitute for clean documentation.

Usually, I take my notes and save them as PDF files, representing a printed final version. Besides putting them in the documentation folders on the network, I email them to my iPhone and keep them in the Books app. This is helpful when I’m not in the facility and I get THAT CALL. I can refer to my notes and put myself in the mindset to resolve the issue.

Any good manager will appreciate good documentation. It will also be appreciated by all who follow you. This industry is small. Why be known as the guy who did not document?

Yes, I have worked with managers who did not appreciate documentation and deleted the information; but there is no excuse for being stupid.