Here in the 21st century, it’s difficult to imagine broadcast automation without thinking of computers; you can’t have one without the other. But it wasn’t always this way.

Computers and automation systems have both been around for a long time but the two worlds didn’t begin to merge in a big way until the mid-1970s, when IGM introduced the 750 system with a DEC PDP-8.

Most of the hardware, playback media and terminology of these earlier analog systems is long gone and forgotten. That means it’s time for a ’70s flashback.

FLASHBACK

Let us don our wide-lapeled, burgundy, three-piece polyester suits, set the date for April 1974 and dive headlong into the time machine.

We emerge just in time for the opening of the NAB show of 45 years ago, and we visit the Sparta booth to see what’s new in broadcast automation systems.

At first glance the three racks of equipment look intimidating. But when we break it down, we see that it’s just audio tape reproducers, a controller or some sort, and ancillary devices such as silence sensors and logging equipment.

The first thing we’ll look at are playback systems.

Unlike the digital audio files of today, there were different tape media for different lengths of content. Most of the music, especially for the popular beautiful music and easy listening formats of the day, was recorded on larger 14 -inch NAB reels of 1/4-inch tape.

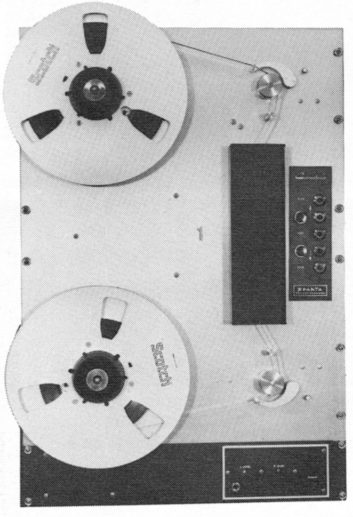

Sparta’s Corinthian was one such machine. With 1 mil tape rolling at 7.5 inches per second, six hours of content were stored. Foil leader at each end of the tape would reverse the machine at the end of three hours and switch tracks. Stereo decks were available in half- and quarter-track configurations. The capstan was direct drive with a synchronous motor, giving a timing accuracy of 99.8%.

While Sparta built their own 14-inch playback machines, other automation system manufacturers used the popular Scully Model 270.

With other formats, some stations preferred to have reels with music from different categories, and conventional playback-only recorders with 10-inch reels and auto-reverse were employed. Again, Sparta manufactured their own machines, while other companies used a variety of recorders, from Revox A-77s on the economy end to Ampex 440s on the premium side.

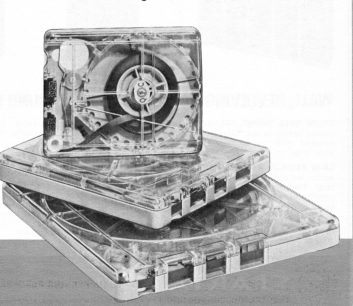

Commercials, PSAs and jingles usually were recorded on NAB “A” size carts, which could hold about 10 minutes of tape. Several commercials could be be recorded on each cart, so they could be played in rotation. Carts were loaded into Sparta RS-224 carousels, which held 24 carts each. Depending on the size of the station, format and commercial load, there could be as many as four carousels in an automation system. Automation often had a separate rack-mounted cart machine that could handle A, B and C carts, dedicated to top-of-the-hour station IDs.

MAKE IT SOUND LIVE

One of the criticisms of early automation systems is that they lacked a “live” sound. But:

Here at the 1974 NAB, we see that problem being addressed.

There in the rack of Sparta’s demo automation system is a TA-581 time announcer. And what an amazing piece of equipment it is. When the salesman slides it out on the drawer, we see two C-size carts that hold the time announcements, one for odd minutes, the other for even. Time checks can be programmed as events. We’re told that we can purchase pre-recorded carts with the time announcements, or make up our own, for a more localized feel.

The clock is controlled by a crystal oscillator, making it super accurate, according to the salesman. The only reference time signals available to us in 1974 are from the National Bureau of Standard’s WWV, and the network tone at the top of the hour. That oscillator may drift slowly, so once a month, the salesman explains, it’s good to check it against the network.

The geek in us wonders though: What happens to that clock after a power failure? Won’t it give inaccurate time announcements, ruining the illusion that we’re a live operation?

No worries, explains the salesman. The time announcer is disabled after a power failure until reset, so inaccurate time checks are never aired.

A fairly new arrival in automation systems is a net join, enabling automated stations to join the network for news, then break away for the next event. Sparta’s DC-24 has an LED display for 12- or 24-hour time, driven from a clock that is almost identical to the one found in the time announcer. Plug-in time cards or thumbwheel switches are available for selecting program fade, network join and break times. The DC-24 can control up to four timed events per hour. It also provides timing signals for program time correction. And just in case something goes horribly wrong, pushbuttons on the front panel can manually do the network join functions. Although we don’t see one on the show floor, there are other network join devices that work off the tones sent by the network just before the newscast begins, and immediately after it ends.

Every station’s requirements for automation are different, depending on format, commercial load and market size. Each Spartamation system is custom-built to customer requirements using the aforementioned components.

That just leaves one question. How did automation systems do all of this, and more, without the use of computers?

The short answer is that it was fairly easy, albeit without much of the flexibility that we take for granted today.

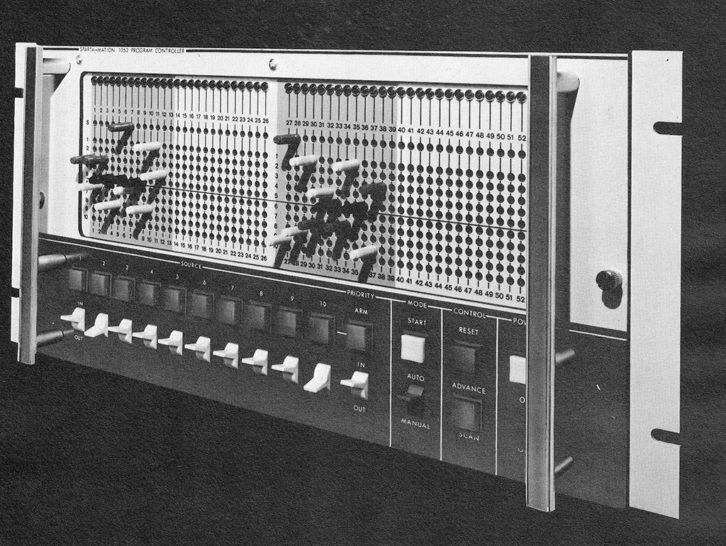

The brains of Spartamation (also spelled as Sparta-Mation) was the 1052 automatic program controller. It delivered automatic start/stop control and overlap audio switching for 10 sources, plus two special channels for network and fill music. The basic model had a 52-event format capability, with an 11 x 52 matrix board for the format information.

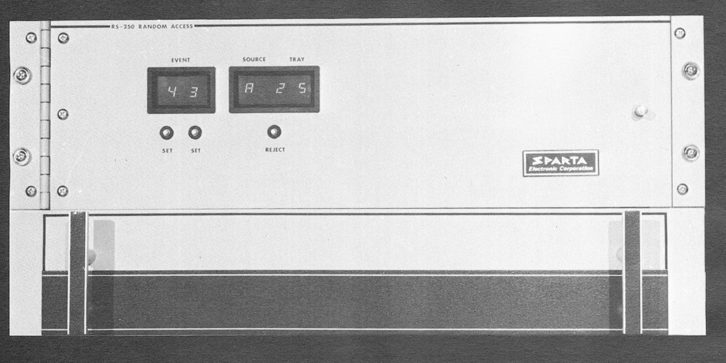

For greater flexibility with carousels, the RS-250 Random Access could be purchased, as it acted as a sub-programmer for the 1052 controller. Once it was installed, two carousels (48 carts) appeared as a single source to the 1052. The 250 determined which carts would be played, which skipped and in what order. When there was no commercial scheduled for an availability programmed into the 1052, the “skip” setting on the 250 would cause the controller to ignore the play command.

The 250 also featured “search-ahead cueing,” which insured that the other carousel had the correct cart loaded ahead of time, so carousels could play back to back with no dead air. An LED readout displayed carousel and tray number to play next. Event position was programmed via a series of slide switches located in a slide-out drawer. This was the 1970s equivalent of non-volatile memory; event programming would be preserved during power outages.

Carts that were produced for automation made use of the secondary and tertiary cue tones. The 150 Hz secondary tone was added at the end of the audio, and it was the signal to the controller to start the next event. Also, a logging encoder was used to record the five-digit code on the cue track that was used for identification. Selection of the correct digits for encoding was usually made via rotary switches on the encoder.

WARNINGS & LOGGING

While a number of syndication companies, such as Bonneville Beautiful Music, TM Programming, Drake-Chenault and Century 21, distributed pre-recorded music tapes, some stations preferred to create their own. In addition to the usual production facilities, making your own music tapes for automation required additional items. Stations recording 15-inch reels needed a recorder that would handle the larger reels. Also necessary would be an EOM generator to record a 25 Hz tone at 5 dB below reference level for 1.5 seconds on the left channel.

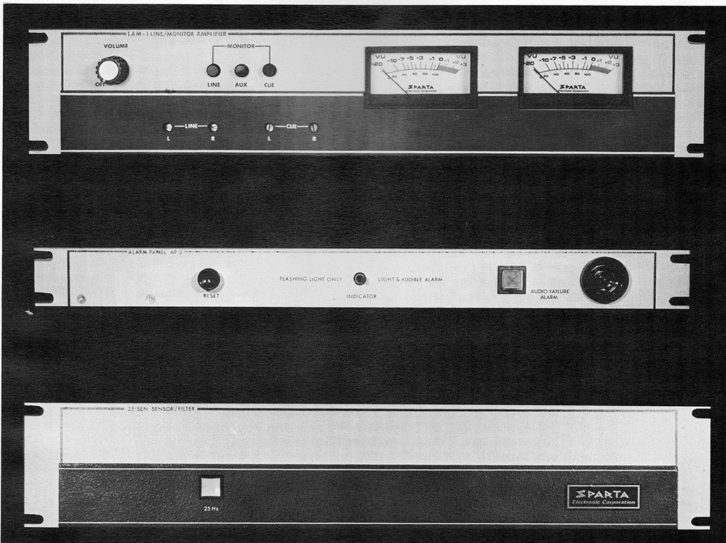

The right combination of cart and tape playback systems, along with a controller and random access, could give a smooth-running automation system. Other essentials included a silence sensor, line amp, 25 Hz filter and program logging.

In Sparta systems, the AP-2 alarm panel would beep and flash a warning light whenever the auto restart function of the automation system had been triggered. Auto restart would advance the program controller by one event when a silent period was sensed. This could be the result of brief power outages or tape/equipment failures. In any event, the operator on duty needed to check the tapes and reset the clock if necessary.

The LAM-1 line amp provided VU meter monitoring of both program and cue levels in addition to the traditional line amp function. Optional plug-in 8-watt monitor amplifiers were available for loudspeakers. Also optional was the HP-40 40 Hz high-pass filter. It would remove the 25 Hz EOM tones from the program output. Otherwise, they could be quite audible over the air.

The demo system at our Sparta booth would have had a CBS Audimax connected to the output to ensure a reasonably consistent level between sources. This was a fairly common practice. Gates systems of the same era usually came with two Sta-Level amps.

The FCC regulations for maintaining program logs applied to automated stations in the same way they did for live operations. Just because a commercial was scheduled to run on automation was no proof that it did run.

A logging system would “listen” to what was played, and create an FCC-compliant program log. For carts and tapes, information encoded on the cue track was coupled with a timestamp in 2400 format from the digital clock. We note that these logs follow the letter of the law, if not the spirit.

A typical log printout might include an entry such as “1317 05218.” To figure it out, we would need the encoder directory, usually maintained by the sales department when commercials were recorded. In this case, we discover that at 1:17 p.m. (i.e., at 1317), the automation played a McDonald’s :60 (because the encoder had assigned the cart for the McDonald’s spot a five-digit code of 05218).

Logging systems in later years would by advertised as English language, meaning that the tedious task of looking up five-digit codes had been eliminated, and the logs could be easily read by someone who didn’t speak binary.

Dot-matrix printers would not be readily available for a few years, and the program log was usually printed out on a teletype machine, similar to the one used at stations for the AP or UPI news service. Some systems used a printer that used a 2-inch roll of paper and looked similar to an adding machine.

As we head back up the aisle toward the time tunnel and our return to the 21st century, we marvel at all the things that were possible with broadcast automation before the integration of computers. We also wonder: Whatever happened to Spartamation systems, since Sparta isn’t recalled as a major player in the automation market? And for that matter, what happened to Sparta itself?

In 1976, just two years after our visit to the NAB, Sparta had become part of the Cetec Broadcast Group, which was a union of five California-based companies.

Cetec Jampro manufactured TV and FM antennas, Cetec Vega made wireless microphone systems, while Cetec Audio continued with Sparta’s line of consoles, including its Series 10 quad boards. Cetec purchased Schafer automation, and it became Cetec Schafer.

Cetec Sparta dropped its automation product lines and focused primarily on transmitters. Sparta had been doing pioneering work on solid-state AM and FM transmitters during the early 1970s, and their SS1000A was the first solid-state AM transmitter type accepted by the FCC. The Sparta AM line featured 1, 2.5 and 5 kW units, while their FM transmitters were solid-state at 250 and 500 watts, and solid-state up to the final tubes at higher power levels. The company also continued to manufacture its Century II modular cart machines, available as triple deck (one motor) desktop and rack-mount units.

Tom Vernon is a longtime Radio World contributor. He wrote here in the previous issue about the history of transmitter remote controls.