The author is national program manager for Copper Development Association Inc.

Proper grounding and bonding in radio and television stations are vital to improving uptime, equipment life and protection against transient events. These steps frequently can be accomplished with little cost while achieving fast payback times. Getting the facilities infrastructure correct is fundamental and should precede many other steps such as installing lightning protection systems or power conditioners.

In this article we examine two such installations where corrective actions and results provided valuable lessons.

KPTH

KPTH operates a 1,988-foot tower and transmitter in northern Iowa. Several years ago, two lightning strikes at different times damaged the two of the guy footings as seen in Fig. 1.

This installation used a grounding method developed in the 1940s by Underwriters Laboratories engineer Herbert G. Ufer; the method bears his name. Ufer grounding consists of attaching the grounding electrode conductor, in this case from the guy wires themselves, to the steel rebar encased within a concrete footing. The Ufer ground usually is a reliable and secure electrode. However, when installed incorrectly or inappropriately for the location, an Ufer ground — when struck by lightning — can cause damage to the concrete, as seen in this case.

Strikes to TV and FM broadcast towers normally should shunt harmlessly to earth by the tower grounding system, assuming the system is robust and functioning properly. However, in this case, the damaged footing possibly risked the almost 2,000-foot tower.

KPTH called in a power quality expert, Martin Conroy, to assess its installation and recommend corrective action, a prudent step when the staff feels technical problems exceed their knowledge.

Conroy surveyed the existing system and installed a number of key fixes and new ground system components.

The tower was refitted with a new buried ring ground supplemented by three 80-foot vertical electrodes, shown in Fig. 2.

Next, each guy footer was surrounded with a buried 250-kcmil bare copper ring ground. The term “kcmil” is an abbreviation for “thousands of circular mils,” a National Electric Code standard to identify wire sizes larger than 0000 American Wire Gauge (AWG). A “mil” is 1/1000 of an inch. Here, “250-kcmil” is a wire with a diameter of 250,000 mils (0.5 inches).

A horizontal, buried bar-conductor existed between the tower and guy footers, but the existing vertical ground rods at the footers were only 8 feet long, resulting in high resistances. Therefore, 50-foot long horizontal conductors were installed between each of the three guy footers on each leg, supplemented by vertical electrodes in Bentonite backfill that varied in length between 35 feet and 75 feet deep, as shown in the plan in Fig. 3. Bentonite is a mineral clay used in areas with high soil resistivity to enhance connectivity in the presence of moisture, and it acts as a natural sealant.

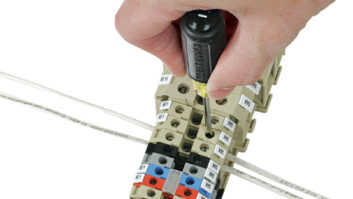

The above ground bonding between ground rod and bare conductors is shown in Fig. 4.

KGBI

KGBI(FM) is a noncommercial radio station owned and operated by Grace University in Omaha, Neb. The station’s studios on the university’s campus are linked via microwave to a 100 kW transmitter and a 1,200-foot (365 m) tower in nearby Springfield (Fig. 5).

Large thunderstorms occur regularly in this area. KGBI’s tall tower has received its share of lightning strikes, and every so often ¾ too often, in the eyes of the licensee ¾ an exceptionally powerful strike would damage the transmitter or the all-important HVAC system.

Bob Drake, who was then KGBI(FM)’s chief engineer, had seen this sort of thing before at a sister station, KROA(FM), and had a strong hunch about the cause.

“A few years ago we encountered serious lightning-related safety issues at KROA,” said Drake. “We solved those problems by upgrading the station’s grounding system. As soon as we did that, we noticed that the station’s reliability and performance also improved dramatically.”

When the transmitter and tower complex were built, its contractor installed a relatively simple grounding system consisting of one chemical electrode located between the transmitter building and the tower (Fig. 6), plus three 10-foot (3-meter) copper-clad rod electrodes between the tower and the perimeter fence. A chemical ground electrode is a metal pipe containing electrolytic salts that slowly permeate the surrounding soil and increases its connectivity.

Most of the original system was connected using bare 4 AWG and 00 AWG copper conductors, but there was also a thin strip of copper running between the tower and a nearby electrode, and to the chemical rod. It was connected with hose clamps and U-bolts (Fig. 7).

Martin Conroy, again the grounding expert involved, said, “We concluded that one major cause of KGBI(FM)’s problems was high ground resistance. Some of that resistance was attributable to the shallow electrodes and some to the flimsy and possibly corroded connections in the exterior grounding system. Lower-resistance grounding electrodes, preferably several of them, were needed.”

He said, “The station already had transient voltage surge protection, but we wanted to improve its grounding connection to make sure it worked when needed. Finally, we believed the entire system would be improved by installing a ring-ground, tying in exterior auxiliary equipment and providing better lightning protection to the transmitter building.”

Based on his recommendations:

● The chemical electrode would remain, but additional 50 feet (15 meters) deep low-resistance rods were driven at points surrounding the tower, adjacent to the emergency power generator and at the service entrance, the latter serving as the site’s primary grounding electrode.

● A 250-kcmil copper ring-ground was installed in a trench outside the perimeter fence (Fig. 8). Corrosion-resistant copper alloy clamps were used to bond the ring-ground to the fence, the antenna tower and the network of cables connecting the grounding electrodes. The final pattern resembles a web with electrodes at major intersections.

● Bonds were also made to the pedestal of the HVAC equipment, the emergency generator and its fuel tank.

● An external 250-kcmil copper halo ground was installed on the steel flashing of the transmitter building’s impact-resistant (against falling ice) concrete roof. Copper down-conductors connect the lightning rods with the rest of the grounding system.

● Inside the transmitter building, a halo ground was constructed by mounting 250-kcmil copper conductors on the walls. Copper conductors descending from the halo were bonded to all conduits, cable trays and equipment cabinets in the building and to 1/4 inch (6.3 millimeter) twin copper collector plates mounted on interior and exterior walls. Additional 250-kcmil cables connect the plates to the ground-neutral bus in the service entrance panel and to the primary grounding electrode.

● Larger copper equipment grounding conductors were installed in the transmitter electrical feeder.

THE RESULT

Since the new grounding system was installed, there has been no damage to the transmitter or its auxiliary equipment. More important, the station now operates so reliably that the university has been able to attract an additional FM station to the facility and has added a second transmitter building to the site.

OTHER SUGGESTIONS

The bonding and grounding of a facility is the foundation of everything else. Surge suppression devices or a lightning protection system need robust, low-impedance grounding to which they can discharge the excess energy.

The examples cited point out several common installation errors that can be prevented or corrected easily and inexpensively. One of the principle recommendations is to make sure all elements are joined into one grounding system. Separate, independent grounds mean the respective pieces of equipment may be at different potentials, sometimes with the earth serving as a conductor between them.

Also check the resistance on a regular basis. Inspections at least annually are suggested to determine if there have been any unexpected large changes. If so, find out why.

Another important recommendation is to have a written plan for every installation that includes grounding. Various contractors may install or service different equipment, paying scant, if any, attention to how that piece of equipment fits into or may affect the grounding system. Separate contractors may install different elements of the whole, without knowing their interdependence.

Finally, inspect the installation or service to ensure conformance with your written plan. Remember, you only get what you inspect, not what you expect.

CONCLUSIONS

Proper grounding, bonding and wiring of a facility with sensitive equipment, be it a communications center, data center or even medical facility, should be the first item considered when constructing or renovating a site, or correcting known problems.

Similar to installing a correct foundation to support any activity, a correct electrical infrastructure is fundamental, and usually cost-effective compared to the down time or equipment damage that can result. In fact, retrofits like installation of a lightning protection system can worsen conditions if not connected to a robust, low-impedance, low-resistance grounding system.

Assuming the electrical items are correct, the next most important item is a written plan or set of instructions that every contractor or supplier must meet. And their finished product must be inspected or their work verified to meet requirements.

Last, if unsure of any phase of proper power quality installation, do not hesitate to call a professional for assistance. The cost is minimal to the risk.

For more information about grounding or lightning protection systems, visit www.copper.org.