Once in a while, a new tool comes onto the scene that makes a big difference in the way we operate. I’ve seen this a number of times in my 40+ year career in broadcast engineering. One that comes to mind immediately is the operating impedance bridge.

A well-equipped drone can provide an engineer with a lot of information on a tower or antenna.

Before we had the OIB, we pretty much had to guess at the driving point impedances of directional array elements, and as such, we had to design our systems to operate with elevated VSWR and a lot of adjustment range in the matching networks.

Then along came the OIB, and suddenly we were able to get a look under the hood — with the engine running! We could measure and know what those driving point impedances were and could nail the match on the transmission lines, improving bandwidth, stability and reliability of our AM directional arrays.

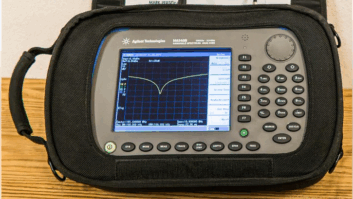

Nowadays, the OIB is ubiquitous and we take it for granted. Some might even look down their nose at it, since we have such great modeling tools and vector network analyzers, but the bottom line is that the OIB is the only device we have that lets us measure an impedance in an AM system under power. Sure, I have VNAs and modeling tools, but I’ve also got an OIB and I’m not afraid to use it.

Another relatively new tool is coming into use right now, and it’s one that, like the OIB, lets broadcast engineers see something that they could not observe without it. I’m talking about the small unmanned aircraft system (sUAS) or “drone.”

GREAT SHOTS ROUTINE

Anyone who is a fan of the many great reality shows on Discovery and other television networks has seen the transformation that the GoPro camera and sUAS have brought about. With these two devices, often used together, the producers now routinely get great shots that would have been impossible or prohibitively expensive in the past. Once in a while, I see a scene where it’s fairly certain the GoPro camera was damaged or destroyed in the process of getting a shot, but the microSD card (obviously) survived. There’s no way producers would take such risks with any other cameras.

[Read how Sam Wallington of EMF is making creative use of drones.]

And of course they get those great aerial shots that in times past would have required use of manned rotary wing aircraft. Some shots would have been impossible even with a helicopter because the rotor wash would have affected the shot. Not so with the drone. It is small, light, unobtrusive and is able to get in really close with very little or no impact on the environment around it. I just love those “hero shots” in the opening credits of “Gold Rush” where a drone is flown right at and over the main characters, often coming within a few feet to get the desired effect.

That capability has brought drones into common use in broadcast newsgathering. Every year at the NAB Show, I enjoy watching the drone product demonstrations, and every year I notice the trend: smaller, lighter and more capable. Those same characteristics are beginning to bring drone technology into the broadcast engineering arena, specifically in the area of tower and antenna inspections.

Tower climber/engineer Derek Jackson repairs a lightning rod on the top of a 375-foot tower near Denver International Airport in a drone photo. Drones let engineers on the ground see what they have never been able to see before.

EASING TOWER TASKS

Broadcast engineers who are tasked with the care and feeding of antenna towers, antennas, transmission lines and tower-mounted electronics, have long been at a disadvantage in these endeavors. They had to rely on the eyes and hands of others, often ironworkers or other non-technical tradesmen with little or no knowledge of what makes antennas, transmission lines and other tower-mounted radio/TV infrastructure tick. The drone is starting to change that.

While a drone can’t install antennas, align microwave paths, hang transmission line or replace antenna-mounted microwave radios, they can do a lot in the preparation for those tasks. For example, a tower can be “mapped” in short order using a drone. This is the first step in optimizing an antenna, designing a directional FM antenna or doing a structural analysis. In the past, a climber had to spend hours on the tower taking photos and making notes. Now, a licensed sUAS pilot can run the drone up and down the tower faces while shooting high-resolution video, stopping to take still photographs of areas of interest.

This same process can be used in preparation for an antenna installation. The high-resolution video and photographs can be used to “scout” the mounting location, looking for likely attachment points and cross-members, guy attachments, transmission lines, conduits and other appurtenances that might interfere with the antenna mounting. If the leg diameters are known (from factory structural drawings), measurements can even be scaled off of high-resolution straight-on photographs. It’s easy to see how a preliminary climb can be eliminated altogether.

In some of my own drone photographs and videos, I discovered that indicator lights and diagnostic displays can often be viewed, giving the engineer some clues to a problem with a microwave radio, for example. Is it getting power? Is it getting Ethernet? Does it have a link with the other end? Often there are external indications of these things, and knowing them can help the engineer resolve the problem, perhaps from the ground. At the very least, this information can better prepare the tower worker who may have to go up to replace a radio, cable or power supply.

How often do towers get inspected as a rule? Annually? Every two years? With a properly equipped drone, the engineer responsible for a tower could do a thorough visual inspection at whatever interval is desired, certainly much more frequently than an expensive inspection climb might be done. Trouble with loose hardware, broken transmission line and conduit brackets/clamps, coax connections, tower light fixtures and paint can be detected very early on, likely making repairs feasible as opposed to more expensive replacement.

As you can probably tell, I am excited about this new tool I have at my disposal. I have my FAA Remote Pilot certificate with Small Unmanned Aircraft System rating, so I’m legal to fly our drone commercially for all these purposes.

Getting licensed isn’t all that hard or expensive, and you can get a well-equipped sUAS for about a quarter of the cost of an OIB. My guess is that it won’t be long before drones in the broadcast engineer’s toolbox are just as ubiquitous. And take it from me, they are a lot more fun to use.

Cris Alexander, CPBE, AMD, DRB, is director of engineering of Crawford Broadcasting Co.