(click thumbnail)Fig. 1: Keep metal mesh filters clean.Ed Bukont of Commstruction and Services remarked about our reminder to check filters and heat sinks on solid-state transmitters, often overlooked because the transmitters run so reliably. Ed reminds us to check filters on sub-assemblies as well. This includes controllers, solid-state IPAs or an exciter mounted inside the transmitter. Ed adds that even the HD Radio signal generators are filtered and shouldn’t be overlooked.

Clogged filters will cause overheating and eventual thermal shutdown. Many of the filters used in these assemblies are metal mesh-type filters, as seen in Fig. 1. When they’re clogged, airflow can be cut in half.

Cleaning is simple, but do it when the transmitter and associated assemblies are off. Even small muffin fan blades can cause serious injury when moving. Ed suggests having at least one spare for each assembly so they can be rotated and cleaned at your convenience.

(click thumbnail)Fig. 2: Dirty fan blades reduce efficiency.

These small, mesh filters can be cleaned with a vacuum and a brush, then stored for the next rotation. If you’ve inherited a poorly maintained transmitter, also check the fan blades for dirt buildup, while the filter is being changed. Dirty blades also reduce efficiency. A cotton swab or rag dampened with isopropyl alcohol should remove the residue.

Of course, ensure all power is removed before attempting any maintenance on fans or blowers.

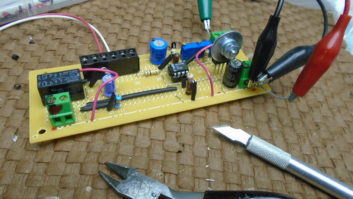

Can you guess what the contraption in Fig. 3 does? Think on it and we’ll have the answer later in the column.

Vern Killion, engineering manager at KRVN(AM/FM) in Nebraska, writes about the INA217AIP, which is a plug-in replacement for the obsolete SSM2017.

(click thumbnail)Fig. 3: Can you guess what this contraption does?

The SSM2017 is an 8-pin DIP package, used as a low-noise, high-quality input amplifier. It’s seen in many professional broadcast audio products including the Comrex HotLine and Orban 9200.

The replacement INA217AIP can be ordered from Digi-Key at (800) 344-4539. The part number is 296-13452-5-ND, and the cost is about $5 each.

When searching for solid-state devices, Vern’s found that the web site www.findchips.com is excellent and faster than Googling for devices still in production.

Dale Tucker handles sales for Radio World, primarily on the West Coast. Dale is always finding neat companies with products that make engineer’s lives easier.

(click thumbnail)Fig. 4: The solenoid resets the circuit breaker.

Recently, he was talking to John Browne at K-Y Filter. John’s company makes what are perhaps the best filters for dealing with RF in phone lines, always an issue for a broadcast engineer. You can get more information from the web site; go to www.ky-filters.com/am.htm

When you order, tell John you heard about his company from Radio World’s Workbench column.

With transmitter sites scattered in so many directions, it can be a real stretch to be at multiple sites, especially during storms.

Fig. 3 shows one engineer’s solution to tripped breakers. This could save you from having to drive forever just to throw a circuit breaker.

(click thumbnail)Fig. 5: A side view of the reset assembly.

I’ve heard of engineers with mountaintop or desert sites who encounter occasional current surges that trip the high-voltage power supply breaker. The breaker does its job, guarding against the momentary short; but the transmitter won’t come back on until the breaker is reset.

The solenoid assembly connected to the remote control resets the breaker remotely, saving a long drive.

There are caveats. First, this is not a factory-approved modification for Continental or any other transmitter. The engineer who devised this auto-reset assumes full responsibility.

Although this approach saves you time, new problems arise when you choose to reset the breaker by remote control and not in person. You really don’t know why the breaker tripped; and by forcing a restart you could cause further damage to the transmitter.

For that reason the function is unlabeled on the remote control. You won’t have some operator performing multiple resets in an attempt to get the transmitter going, making a bad situation worse.

Conversely, when one engineer must maintain multiple sites, he sometimes has to think creatively. Risky, yes; but faced with multiple late-night drives to the transmitter just to reset a breaker, I can understand the rationale. An engineer can ask for an assistant only so many times before he realizes it’s not going to happen.

We’ve all seen engineering kluges. But I’ve got to give this engineer – who will remain nameless – credit for doing a nice engineering job in putting the auto-reset together. Everything is sturdy and well-mounted; even the leads to the solenoid are shrink-wrapped to minimize any shock hazard.

The addition of the spring ensures that the quick action of the solenoid plunger doesn’t rip the breaker handle off. This certainly was thought through.

Like it or not, many engineers have been forced to resort to such “tricks” to keep stations running.