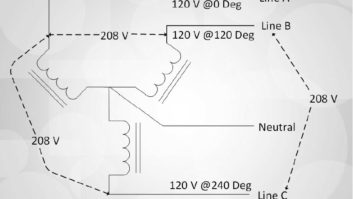

Walt Billings of Total Engine Service and Supply in Baltimore noted the column in which it was suggested to keep hard-drive systems on the same electrical phase, to avoid ground loops and similar gremlins.

“A great idea, as long as you keep each phase balanced with regard to the current draw. Loading up one phase at the expense of the others can lead to performance problems – especially if you use a generator!”

Too much load on any one phase may cause the generator to trip its breaker – not good for a backup system. Walt’s company services and sells used and new generators, and though the Y2K planning kept him busy, he remarked that many of his customers now have a good backup system.

Now that a date-specific event is past, the backup can be used for other events like wind, snow, ice – those catastrophes that cannot be anticipated.

So how much is too much? Walt gave an example for a 50A panel. Code states that the current draw must not exceed 80 percent, so in the example, that’s 40A per phase.

When measuring the current draw between phases, a good rule of thumb is for each phase to be within + 5A of each other. By keeping the loads balanced, hot spots are eliminated.

The goal is for all poles on the breaker or contactor to heat evenly. As the current draw of the load shifts, the connections heat and cool, leading to loosening of the wires.

Significant load shifts at the studio may not be commonplace; however, loading up all the tower lights on one phase at the transmitter site is another story. Some generators sample one of the phases to sense the voltage for the voltage regulator.

If all the tower lights are run off this same phase, disaster lurks. With pulses every three seconds or so, it won’t take long for the generator to try to react as that one leg is pulled down to flash the lights. A blown voltage regulator or worse can result.

A clamp-on ammeter can point to any problems, and a licensed electrician is best used to correct or balance the load.

. . .

(click thumbnail)Figure 1: An ‘L’ bracket holds machines in placeRemember Figure 1? If you guessed the back of an ITC, you’re right.

The point I want to make is the “L” bracket that Brian Edwards of WUST/New World Radio in Washington has screwed into the back of his Middle Atlantic Rack Shelf.

(click thumbnail)Figure 2: Can you find four things done right at this transmitter site?

This technique works for consumer gear as well. Cassette, MiniDisc and CD players can be set in an inexpensive rack shelf, and the brackets keep the gear from getting pushed around by heavy-handed jocks.

Another tip will help if you have fused equipment with rear-mounted fuses. Velcro one of those small plastic fuse boxes to the rear of the machine or rack shelf. Keeping the box stocked with the fuses you need will speed repairs.

Here’s another brain teaser. Take a look at Figure 2 and see if you can find four things done right at this transmitter site.

. . .

(click thumbnail)Figure 3: hang RFR signs inside the fence, but don’t use white ties!

Clif Glasgow handles a group of stations in the Imperial Valley of California, better known as the desert Southwest. In this climate, even black ty-wraps die after six months of scorching sun. An inexpensive alternative is #14 or #12 TW insulated solid copper wire. For bundling wires or cables on a tower or satellite dish, Clif suggests Band-Its. These are black vinyl-coated stainless steel bands, which are self locking and reusable. Expensive in comparison to ty-wraps, but they last forever. Figure 3 shows hanging an RFR sign inside the tower fence to deter vandalism.

The white ties used in this photo won’t last long in the sun, so resort to Clif’s copper electrical wire – it’s usually in plentiful supply around transmitter buildings, and you can’t beat the cost!

. . .

All right, did you find at least four things done right at this transmitter site? One is having a flashlight – with fresh batteries – right by the door. A second is having main and backup air conditioning or ventilation.

Third is having the thermostats marked, so you know what each one does. The fourth is running all low-voltage wiring (for the thermostats) in conduit.

Ready for some extra credit? The erasable note pad ensures that things like air filters or spares are ordered.

Submissions for this column are encouraged, and qualify for SBE recertification credit. Fax your submission to (703) 323-8044, or e-mail to [email protected]