John Hosford, director of engineering at Montpelier Broadcasting in Vermont, sometimes is surprised at what we publish in Workbench, because he finds that he’s been doing whatever it is for years.

Fig. 1: Take advantage of the APC Smart Slot option. For example, we recently discussed labeling of power cords and wall warts; Jon picked up that idea from Workbench years ago, but agrees that it’s worth a reminder, especially for folks new to the industry.

In addition to labeling plugs and power supplies, Jon labels both the back and front of the gear in a rack. We all need to walk non-technical people through things on the phone; his labeling practice helps them when resetting power or moving a cable on the correct piece of equipment.

Jon tries to put the label near the unit’s power plug if it’s removable, because rebooting power is the most common thing he asks others to do.

He adds another tip: Many APC uninterruptible power supplies have a Smart Slot expansion option, seen in Fig. 1. APC has a module for Smart Slots called a Relay I/O Module (part #AP9610). The module offers inputs and outputs via relay contacts to monitor and control the UPS.

At a remote site with a transmitter remote control, this gives you the ability to reset a UPS or monitor whether it’s operating on battery via standard contact closures. The module has controls to turn the unit on, off,gracefully off and run the self test. The outputs are for “on battery,” low battery, replace battery, overload and fault.

With this card, you can reset a unit remotely should it lock up. Anyone with a UPS at a transmitter site knows this can happen. If you don’t have AC line monitoring on your remote control, this option will, at the least, indicate the UPS isn’t happy with the AC line power and that it has switched to battery.

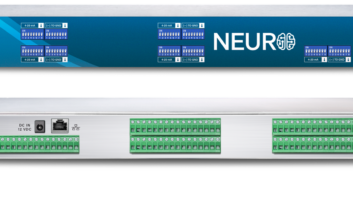

As you can see in Fig. 2, the card comes with a nice breakout removable connector with screw terminals. Note that the unit expects at least 1 second of stable contact closure to be considered a valid input command. That means some remote controls will need their output command time lengthened.

Fig.2: The relay I/O module offers a variety of uses. Commercial-grade UPS products that accept this module are not the least expensive, but Jon has found that cheaper ones from APC often don’t like genset power, so they run on battery (and eventually die) the whole time the building is on auxiliary power. The commercial-grade units also have settings to make them more tolerant of the slightly incorrect power that a genset can produce, and to turn off that darn beeping “on battery” alarm. For this reason, Jon justifies spending a little more.

APC also offers modules for SNMP, 10/100BASE-T, serial, Modbus, Out-of-Band management, environmental monitoring and more.

***

Gary Wachter, director of engineering for KKDA(AM/FM) in Dallas, agrees that labeling wall warts and plugs using a Brother P-Touch labeler is a great idea. But he found that labels have a tendency to fall off over time; either they are too stiff, or what they are attached to is too rough.

Brother makes an inexpensive TZe Series of labeling tape that cures these ills. The Flexible ID Series, designed for cables, comes in various widths and can be wrapped completely around a cable or made into a pigtail. Either way, the label sticks to itself and will not come off.

The text can be printed lengthways or sideways. If labeling across the width of the tape, make sure that the printer can accommodate the wider tape. The TZe-FX251 is 24 mm (0.94 inches) wide. These tapes are not usually on display at the office supply stores but can be special-ordered, or purchased online. Head to radioworld.com/links to find out more.

Gary Wachter has been actively involved in broadcasting for more than 40 years.

***

Broadcast engineer Mike Payne points out that roller inductors can become intermittent and cause issues, especially in phasors. Sometimes you don’t have proper cleaning materials at hand when you spot the intermittent.

A nifty trick that works for Mike is to apply a light film of WD-40 or similar lubricant. This will clean and lube the parts nicely. However, the oil can attract dirt; and if you use too much, it can get gummy, possibly making the situation worse.

Visit radioworld.com/links for a caution about using WD-40 in electrical/electronic applications. An alternative is Caig Labs’ DeoxIT. We’ve got links to both companies’ application notes at the links page.

While we’re on the subject of phasors, Mike adds that when inspecting those big mica capacitors in a phasor or antenna tuning unit, look for a thin etching that shows through the surface of the ceramic. This is tough to spot the first few times; but the etching can point out a bad capacitor. Make it a priority to keep the glass and ceramic bodies of capacitors clean — of course, with the power off.

As far as rigid feed lines are concerned, Mike routinely runs his hand along feed lines and elbows to check temperature. The plants that Mike tends to are a maze of rigid copper fittings and line sections. The “hand method” is a fast, sure way to find problems, especially if you don’t have an IR thermometer. This inspection includes the harmonic filters, too. Slightly warm is OK; hot is not!

Mike writes that the prices of IR cameras have really dropped. You can pan an area quite easily and see possible problems in real time, then take a photo of the problem, if need be.

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips to [email protected].Fax to (603) 472-4944.

John Bisset has spent 43 years in the broadcasting industry, and is still learning. He is SBE certified and is a past recipient of the SBE’s Educator of the Year Award. He works for Elenos USA, an FM transmitter company based in Miami.