I’m a confessed control freak.

Not the kind who longs to be the unquestioned supreme leader of corporation or a small sovereign state. Rather, the kind who needs to have granular control and telemetry of my remote sites.

Those who know me are aware that I never believe I have enough control, no matter how much I already have. It never seems to be quite enough when some late-night issue crops up at any one of my seven sites.

This is a broad topic worth a series of articles, but for this issue, I’ll focus on the emergency power system.

Sure, you have status alerts to warn you the generator is supporting the load at the transmitter site (or studio), but is that enough? I say no! I will now try to make the case that this is little but the bare minimum — and what do you think of someone who only does the bare minimum? You need some flair here!

At minimum, you also should have status (or metering) to alert you when the generator is running (not necessarily carrying the load), generator line voltage, alarm status (such as over-speed, over-crank, oil pressure, low water level, etc.) and the all-important fuel level. I’ll get to another important bit of telemetry a bit later, but I’d like to develop the justifications for the items I just mentioned before getting to that.

The vast majority of the time, your generator sits quietly at the remote site and awaits its mission to maintain your signal when the lights go out. But if you’ve been the business as long as I have, you come to realize that the generator, with all its moving parts, sensors, batteries, liquid levels and outdoor location, can well be among the most troublesome equipment you have in your purview.

I can’t recall how many times the generator failed in the moment of truth, despite its twice-yearly inspections, weekly tests and various visual inspections by the engineer. Sensors fail without notice, as do batteries, belts, hoses — and then there are the rats that build a nest in the controller and chew crucial wiring (yes, that happened to me in 1984).

Recently in Los Angeles, we had a power outage in Beverly Hills, during which the generator failed to come on online (good thing we had an alternate site — another important topic for another time). The deal was the generator ran during a weekly test scheduled by the ATS plant exerciser (days before the power outage) and then shut down due to an over speed condition. We were unaware of that.

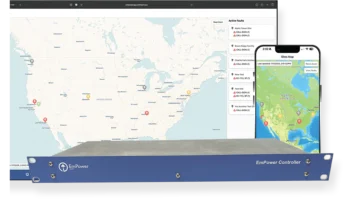

After that, the engineering department came up with a comprehensive “wish list” of everything we should have for generator monitoring. The list included remote generator alarm monitoring (even if only a “summary” alarm), generator run status, load-on-generator status, and a few other, really cool ideas: battery voltage (also alerts you charger issues) and block heater current.

We went to work deploying these ideas for all our sites in LA, and trust me, all the work paid off, particularly when coupled with email/text alerts.

For example, we knew a battery was dead before that became a problem, and we knew if a generator failed a weekly test for some reason, such as an “over crank” alarm.

It was a lot of work up front, but this pays long-term dividends. Newer generators may come equipped with web servers, and better yet, SNMP — a godsend as you’ll have access to every parameter available to a service technician.

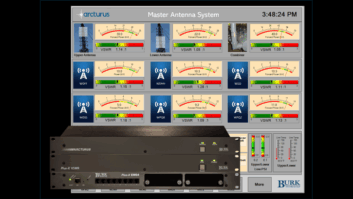

I have included a picture of the GenLink software I use to monitor parameters the gen set at my studio plant. Essentially, all these serve to remove the surprise factor from your job, insofar as the critical generator system.

Earlier I alluded to “another important bit of telemetry.” Let’s say you know when your site’s generator is running, when it has an alarm condition, when the site is actually on emergency power, and if the battery charger or block heater has failed.

That’s still not enough — has the normal power returned yet? You’ve checked your utility’s outage website, and you see they’re aware of the power outage and have “dispatched a crew” but can’t be sure when the power has been restored, unless the Automatic Transfer Switch switches back to utility power.

I know that waiting for that to happen can seem like days. So, some time ago while an ATS was being installed and still de-energized, I added metering on the utility side, so that I would be alerted when the utility power was restored. In that fashion, I knew the generator had 30 minutes more to run, because that is how I choose to adjust the Time Delay Emergency to Normal setting system in my ATS.

You just can’t have enough of this stuff, folks. Let’s resolve to reduce or eliminate unscheduled site visits!

Dennis Sloatman is the director of engineering and IT for SummitMedia Corp.’s Richmond, Va., stations.