A current Radio World ebook explores trends in the use of AI in broadcast radio technology.

In 2022 the Federal Communications Commission allowed computer modeling of directional FM antennas. The action was prompted by a petition from antenna manufacturers and Educational Media Foundation.

Dielectric was a key proponent. It said the new rules would ease product-to-market timelines, helping broadcasters upgrade facilities quickly.

We asked Director of Electrical Engineering Nicole Starrett about the role of AI in its process.

Radio World: What is AI-driven simulated modeling of antenna patterns?

Nicole Starrett: This simply represents using AI tools to do the same types of physical antenna pattern studies that we have provided for decades here at Dielectric. We take all available tower information and bring that together with the FCC protect envelope and any customer specific requests, then plug it into our software and AI tools that we use to optimize each pattern.

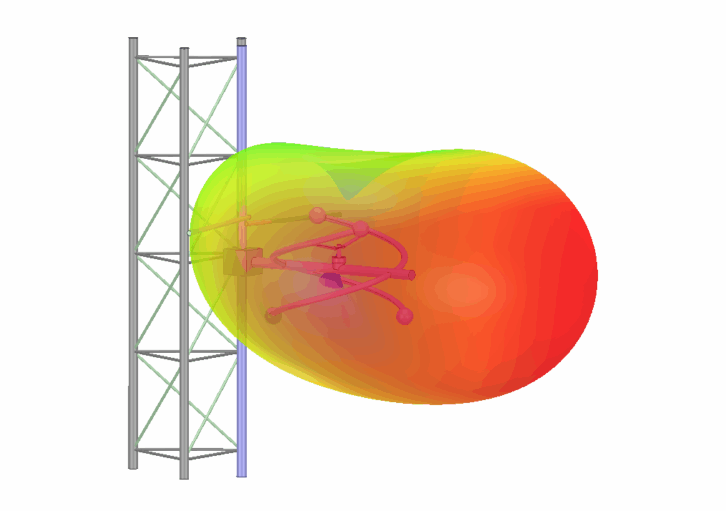

Specifically, we use High-Frequency Simulation Software, or HFSS, to help drive the computer simulation process for virtual antenna design. HFSS eliminates the lengthy setup and breakdown times of physical models.

That is further aided through OptiSlang, an optimetric AI tool that reduces the labor involved in pattern development to one hour or less. Ultimately, transitioning from a physical to a virtual design process allows us to optimize radiation patterns without time and material constraints.

RW: Computer modeling itself has been around in AM and in other contexts for some time. How does AI-based modeling improve upon what computer modeling could already do?

Starrett: Computer modeling has existed in many capacities for decades and has been in use at Dielectric since the early 2000s. The beauty of adding AI as a layer on top of that simulation is that it takes out a lot of human error and the human time that goes into these simulated patterns.

Going from manual patterns to simulation already removes many errors, but it also is time-intensive. It requires watching the pattern as it develops and using your own engineering intuition to adjust that pattern, so it arrives at the customer’s vision. With AI, you can give it a set of parameters, objectives and geometrical constraints. It will then apply all of those to your model and pattern to optimize it without requiring a human to think about it.

RW: What third-party AI tools, if any, do you use?

Starrett: We use Ansys Electronics Desktop and Ansys OptiSlang programs for the AI portion. We do have some internal data manipulation software that we use, but the AI portion is Ansys.

RW: Can you describe the basic process of modeling?

Starrett: It begins with our customers. We have a conversation with the customer and our sales team to identify the desires for their pattern and discern their coverage requirements. They detail the style of antenna they prefer, how much power they can put into it and their designated market area. We then gather all physical information about the tower, including leg size, face size and orientation, which helps us understand the potential aperture of the antenna.

[Related: “Dielectric Ships New RingMaster Antennas”]

We take all that information and build a model of the antenna and tower in HFSS, then run a starting pattern to get a good idea of what it looks like from a performance standpoint. From there, we will determine our objectives, our geometrical constraints and all the information that needs to go into the OptiSlang for the AI portion. We plug it in, run the program and review the results. Those results deliver a selection of patterns we can present to the customer.

That transitions into an iterative process where we make gradual adjustments and improvements, such as shifting the direction of signal. Those constraints are sent into OptiSlang once again, and the process repeats until establishing the precise pattern that the customer wants.

RW: For someone not familiar with the process, what kind of problems are avoided with this approach? I’m thinking here of issues mentioned on your website like problems with the range or anechoic chamber, or the reliability of azimuth patterns and H/V ratios.

Starrett: We have decades of experience successfully establishing physical range patterns. Nevertheless, the process relies on humans to physically adjust and measure the model. Some technicians are incredibly precise, but you never know how much error the process will introduce. Moving to simulation has helped to eliminate many of those errors. With HFSS, we can produce exact point-to-point measurements. We know exactly where everything is. As for anechoic chambers, they’re somewhat lossy and essentially provide an imperfect environment.

RW: In what other ways does Dielectric use AI technologies in its workflows, in making products or in running your business?

Starrett: Dielectric uses AI in some of its product designs, including filters and combiners. Ansys offers tools to optimize filter topology as well as combined performance.

[Read More Radio World Stories About Artificial Intelligence]