One of the best tools in the engineer’s lightning protection toolbox is a tried, true and frequently underutilized friend, the ferrite toroid.

The principle is quite simple. If you have two (or more) conductors passing through a ferrite, such that the net sum of their currents is zero, then the ferrite is an inert object, just sitting there waiting for something to happen.

If, as in the case with a surge or lightning strike, the current on any conductor increases, such that the net current is no longer zero, then the ferrite core saturates, creates a magnetic field and attempts to induce an equal and opposite current flow in the other conductor(s) — in effect, trying to maintain the zero net total current.

[Subscribe to Radio World Engineering Extra]

For this reason, ferrites are a very good tool in many ways, not the least of which is lightning protection. Used on a coaxial cable going out to the antenna system, they can also be useful for finding ground loops.

If you have a ground loop, such that not all of your return current is through the coax shield, the ferrite will saturate — and quickly (depending on the amount of the imbalance between feed and return) get physically warm … in extreme cases, I’ve even seen them explode!

Easy to Install

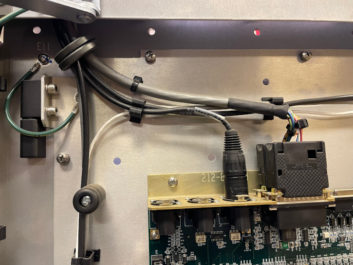

You want ferrite toroids at the output of the transmitter, preferably before the point where the coax shield is connected to the station reference ground (usually where the coax enters the building, but not always, so keep an eye out). The photo in the first image was taken at an AM site.

In the course of the installation, ferrites can and should be placed on pretty much every current carrying conductor, including AC lines, remote control feeds and audio/AES lines (don’t forget the STL antenna cable).

Nautel provides a handful with every transmitter that goes out the door, to ensure your installation isn’t held up for want of some basic protection. Talk to your sales rep if you think you need more.

For any cable where there is a safety ground connection (for example, the antenna feedline ground referenced above, or an AC mains surge protector), ensure the ferrites are installed between the ground and the equipment being protected. That makes the reference ground connection look like a better path than the equipment, by raising the effective impedance lighting or surge current has to overcome to get to the equipment.

[Read the Complete Oct. 20, 2021 Issue of Radio World Engineering Extra]

The second photo is a 5 kW AM transmitter installation showing ferrites on control, monitor, RF sample and Ethernet cables.

Ultimately, for the purpose of common mode protection (trying to keep feed and return currents equal), size and permeability are somewhat less important than if we were making a choke by wrapping a single conductor around the toroid.

Another use for toroids is helping to reduce pickup (for example, the RF from your AM station getting onto the audio feed for your FM station). The principle is much the same as for lightning protection: The ferrite will help to filter any signal that is not present in equal amplitudes in both the feed and return paths.

Nautel offers several ferrites that can help, and you can order them via our Parts Quotation Request form at http://support.nautel.com/parts.

Some useful part numbers:

- LXP38 — this is a 3/4-inch inside diameter toroid, good for RF rejection and lightning protection on small signal cables.

- LP23 — a 2-1/8-inch inside diameter toroid, good for most heavier AC cables and coax up to 1-5/8 inches (as long as the connectors aren’t already installed!)

- LP32 — a 4-1/8-inch inside diameter toroid, good for the really big AC and RF cables (again, this won’t fit over a 3-1/8-inch EIA flange, so keep that in mind when planning)

- LA52 — a small (1/4-inch inside diameter) clip on ferrite that helps to keep higher frequency (FM) RF out of control and signal wiring. Impedance curve shows 320 ohms at 100 MHz, so it wouldn’t be so good for an AM station, but definitely useful for a higher power FM.

Before being named sales manager for Nautel’s U.S. Central Region, the author spent 16.5 years as a customer service technician for the company.