Ed Lobnitz, retired principal/senior electrical engineer at TLC Engineering Solutions, wrote the chapter on lightning protection for towers that has appeared in several editions of the NAB Engineering Handbook, including the most recent. The chapter is recommended reading and goes into considerable depth. But for engineers reviewing their air chains and thinking about business continuity in the face of lightning threats, we asked Lobnitz for some general advice and resource suggestions. This article originally appeared in the 2020 ebook “Plan B: Ensuring RF Readiness.”

Let’s assume we are talking about existing, installed systems that are in full operation, including transmission sites, electronic systems and racks, associated buildings and backup generators and/or UPS systems.

The design of such systems, when new, requires considerable thought and detailed design considerations to “lightning harden” facilities so that lightning and its effects are handled so as not to interrupt operations or cause extensive damage to tower sites and associated facilities.

I have previously prepared and have available a “Design Manual for Antenna Systems — Grounding, Bonding and Lightning Protection” for when constructing new facilities is anticipated; it is also useful in evaluating the adequacy of existing installations from a lightning protection standpoint.

In fact, it would be a good idea to review existing installations, using the manual, to provide a base knowledge that existing systems were “lightning hardened” when first installed. (To request this and the other resources mentioned in this article emailed to you for free, see the end of this article.)

As for existing facilities and protection against lightning effects, I would suggest reviewing all existing maintenance procedures and documentation from the time the facilities were constructed and comparing them to the document “Maintenance Guide for Antenna System Grounding, Bonding and Lightning Protection,” which I prepared a few years ago.

Maintenance inspection frequency cannot be overemphasized — especially after any environmental conditions such as corrosive atmospheres, storm frequency and severity, any alterations, or extreme seasonal changes.

The maintenance inspections should include visual as well as complete testing and keeping complete records and test data. Another document I have prepared for maintenance help is a “Site Audit Check List/Report” that can be used as a first-time guide and to build on as future inspections are made. (See end of this article.)

Lightning protection for facilities should always be either UL certified, Lightning Protection Institute (LPI) certified or both, to ensure the installation is properly and effectively protected.

Also, familiarization with Underwriters Laboratories UL 1149 Standard for Surge Protection Devices, 5th edition, and National Fire Protection Association NFPA 780 Standard for the Installation of Lightning Protection Systems, 2020 edition, is highly recommended.

Also important where generators are involved is the 2022 edition of NFPA 110 Standard for Emergency and Standby Power Systems, which includes generator maintenance checklists. The Lightning Protection Institute is similar to UL in regards to lightning protection system and installer certification but is solely dedicated to lightning issues. I used to be on their board of directors and was also on the UL 1449, 3rd edition, committee.

The author has kindly agreed to allow Radio World to share three resources with readers who ask. Available are “Design Manual for Antenna Systems — Grounding, Bonding and Lightning Protection,” “Maintenance Guide for Antenna System Grounding, Bonding and Lightning Protection” and “Site Audit Check List/Report.” There is no cost. Email a request to Editor in Chief Paul McLane at [email protected].

Ed Lobnitz also welcomes questions from readers. Email [email protected].

Maintenance Checklist

This is an excerpt from “Maintenance Guide for Antenna System Grounding, Bonding and Lightning Protection” by Edward Lobnitz. This checklist is part of a discussion about inspecting lightning protection systems, grounding, bonding and related equipment:

- The following data should be taken to the site or reviewed on-site if available:

- As-built drawings.

- Shop drawings or data sheets for all components.

- Prior test reports for:

- All grounding measurements.

- Soil pH.

- Soil resistivity.

- VSWR measurements at all coaxial surge suppressors.

- Prior inspection and maintenance reports.

- Clamp-on ground resistance meter.

- 3-pole ground resistance test meter.

- Digital camera.

- Sensitive clamp-on ammeter.

- Check the following components for corrosion, damage, modifications or removal:

- Coaxial shield ground kits on the tower. Use binoculars or climb tower to make inspection.

- Grounding cable and connections to the tower base.

- Guy wire jumper and ground wire connections.

- Entrance bulkhead cable boots, mounting provisions and grounding connections. Check cable boots for pliability, cracks and leaks.

- Ground bar connections in all racks and RF cabinets.

- Single point ground. Meter and record all values. Compare to previous ground readings. Test for any current flow on each ground connection with the clamp-on ammeter. Record any readings and compare with previous readings.

- Record number of lightning strikes on the lightning strike counter (if provided). Inspect the counter for any obvious damage.

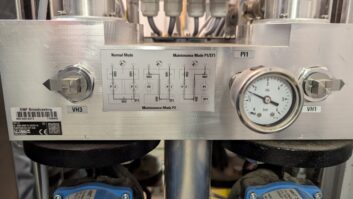

- Inspect all coaxial, low voltage, DC and 120V surge suppression devices related to the antenna systems. Measure VSWR reflected energy at each coaxial suppressor and compare to previous readings. Replace suppressors if VSWR increases more than 10% of if damage is apparent. Replace all suppressors every 3 to 5 years. On low voltage, DC and 120V surge suppressors observe failure lights if available and inspect for damage or inoperative equipment.

- Review all underground grounding cable and strap for any obvious dig-ins or construction activity that might disturb the system. Dig up any suspect areas and inspect grounding continuity.

- Verify that the main building service surge suppressor is still functional by observing failure lights. Proper functioning of this suppressor is important to the life of all low voltage, DC and 120V suppressors.

- Use the clamp-on ground meter to check all building lightning protection downlead ground terminals, walk the roof to observe any damage to the system, such as loose cable supports, damaged, missing or loose air terminals, broken cable, loose connections, etc., the system must be inspected by a UL certified lightning protection contractor and recertified by UL every five years.

- Review generator test logs for compliance with NFPA 110, Standard for Emergency and Standby Power Systems, maintenance requirements. If generator is not being tested, recommend a testing program be set up to test and record data per NFPA 110.

- Test UPS units serving the racks for proper operation. Follow manufacturer’s Maintenance and Test Guidelines.

- Prepare a report of all inspection results, repair recommendations or other suggestions and include an album of all pictures taken, properly identified and referenced in the report as appropriate