Every AM, FM or TV transmitter must be connected to an antenna via some type of cable, normally a coax line. Some lines are constructed with a type of foam between the inner conductor and the outer conductor, while others are hollow.

If your system has the hollow type of transmission line, it is imperative that some type of gas pressure be inside the line. Transmission lines can be vulnerable to corrosion if they are exposed to oxygen and moisture, the two main components that cause a corrosive reaction.

Properly pressurizing coaxial cables will keep moisture out and therefore prevents arcs inside the cable and it improves the power-handling capacity of the coax by increasing the breakdown voltage between the inner conductor and the shield.

Engineers often ask which is more effective, nitrogen or using a dehydrator. The answer is, “It depends.”

If you will be operating the transmission line at or near the power rating of the line, nitrogen will give more protection from arc over. For lower power levels, either will work.

To keep moisture out, the transmission line must be kept at a positive pressure relative to the outside pressure. The pressure required is minimal indeed; maintaining excessive pressure can damage the line and waste energy.

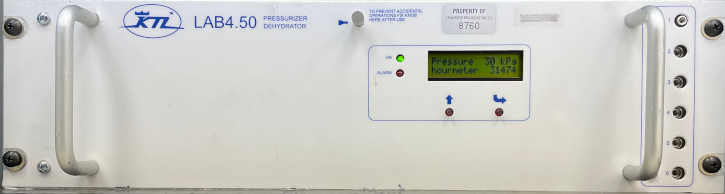

When it comes to dehydrators, proper sizing is everything. If undersized, the unit must run longer in order to maintain pressure, increasing wear on the compressor and driving maintenance costs higher. An oversized dehydrator, however, creates pressure surges in the line. This causes the unit to constantly cycle on and off, again resulting in increased compressor wear and higher maintenance costs.

The most important takeaway point is to have a method to monitor the pressure in the line and an alarm system to notify engineering of a sudden loss of pressure on the line. This could be caused by failure of the dehydrator or empty nitrogen supply. It could also indicate a pending failure in the line itself caused by a major gas leak created by lightning or even a bullet hole.

When installing a new line, it is advisable first to pull a vacuum on the line. This will remove all the moisture from the line. Then fill the line with nitrogen or dry air from a dehydrator. Do not use a standard air compressor for this purpose, since it will fill the line with normal air, which is full of moisture.

This type of failure will be extremely costly and time-consuming. Don’t neglect this important part of your transmission system!

This article was published in the Alabama Broadcasters Association Monday Coffee and Technical Notes newsletter. Learn about ABA’s engineering training academy at https://al-ba.com.

RW Engineering Extra welcomes submissions of stories that help readers solve engineering problems. Email: [email protected].