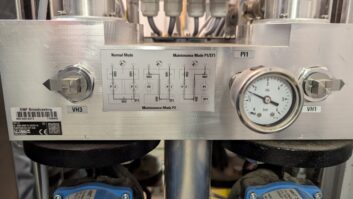

Frank Hertel of Newman-Kees RF Measurements and Engineering likes to save money — or as he puts it, “I’m cheap!”

In one case Frank needed a 5 VDC power supply for the 8 W, 808 nM burning laser he was adding to a homemade CNC machine. Not wanting to spend money and because he already had the parts, Frank repurposed a laptop power supply, regulating it down to 5 VDC.

Frank chose an LM338, an adjustable 5 A regulator. About 1.3 A at 5 VDC is required for Frank’s laser; doing some quick calculations, he proved the required dissipation would seriously stress the LM338.

Frank turned to an old-fashioned trick: a mineral oil heat sink.

As seen in the accompanying photos, he started with a seamless cast aluminum box. This would hold the mineral oil/sand mixture. The only issue is keeping the box upright. Even with the top screwed in place, some wicking of mineral oil is bound to occur. I do wonder if sealing the top with an epoxy or sealing compound would solve that. Let us know.

Frank’s trick works. He included an “add on” involving four power rectifiers in series, inserted between the 18 VDC supply and LM338 regulator. Using the optional series of rectifiers will lower the LM338 dissipation to approximately 8.3 watts of heat. Keep in mind, however, that each of the power rectifiers will need to dissipate the balance of the power, meaning that each diode will dissipate ~3.32 watts of heat. (Note: The voltage drop across each of the power rectifiers will be ~2 volts.)

The captions explain each step. You might also consider this process to build a small test dummy load out of inexpensive carbon or metal film resistors, and using the “sand/mineral oil” heat sink method or just a mineral oil bath for cooling your resistors.

Reach Frank Hertel at [email protected].

***

Fandor.com Director of IT and Operations Tim Pozar has experience in starting community radio stations and working as a chief engineer. A community broadband activist, he now is working on the design and deployment of a non-profit fiber network for the City of San Francisco.

Tim saw our April 25 entry about using duct tape at remotes and had to comment. This tape may be great for holding together a number of things, including making wallets; but it can be costly for laying down wires at temporary locations like remotes, Tim says. Duct tape has a rather strong and sticky adhesive that can leave residue and even damage paint and finish. Hotels will deduct any damage from the event organizer’s deposit.

Although more expensive, Tim suggests gaffer’s tape, made by companies like Shurtape. During strike you will have much less chance of damaging the event site when you rip up gaffer’s; it also doesn’t leave adhesive residue on the cable. Gaffer’s tape comes in multiple colors besides basic dull black.

(Shurtape also offers a website section for HVAC and plumbing applications. It’s interesting to see all of the company’s offerings for securing ductwork and insulating pipes — much more than just “duct” tape.)

Tim Pozar can be reached at [email protected].

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips to [email protected]. Fax to (603) 472-4944.

John Bisset has spent 43 years in the broadcasting industry and is still learning. He is SBE certified and is a past recipient of the SBE’s Educator of the Year Award. He recently joined Elenos US, an FM transmitter company.