Wheatstone said it plans a million-dollar investment to increase its production capacity.

The company, headquartered in New Bern, N.C., said it is making large component buys and an investment in new factory equipment.

“The goal is to double production in its New Bern factory where all Wheatstone and Audioarts products are made, from machining, fabrication, screening and circuit board surface mount to final testing and AoIP system configuration,” it stated in a release.

[Read: Wheatstone Rolls Out the Blade 4]

Wheatstone quoted Production Manager Matt Wilson saying that by keeping manufacturing in-house, it can respond more quickly to changes and have better control over a “volatile” supply chain.

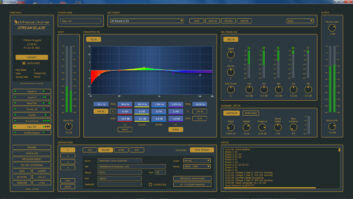

Additions to the factory include a second multi-axis CNC mill and a larger-format brake press for precision metal work. Wheatstone also was an early adopter of surface-mount manufacturing technology, and plans to add another surface-mount machine to its floor to support manufacturing of its consoles, Blades and audio processors.

The company said its recent orders include a multimillion dollar contract that includes WheatNet-IP audio console surfaces, network devices and system preconfiguration for 24/7 studios in 32 U.S. markets, “with the majority of completed systems to ship through September.” It did not identify the customer.

Manufacturers of broadcasting equipment are among those hit by the global instability in component availability. “Lead times on everything down to diodes and capacitors are insane,” Wheatstone’s Dee McVicker said, so the company has increased its materials inventories. “We’re sitting in a really good place, having been able to meet the requirements for one of our largest orders to date plus meeting all of our usual production runs with plenty of parts to spare.”