A couple of years ago, I had the privilege of designing and building a new, state-of-the-art 50 kW transmitter site facility for KBRT(AM) in the Los Angeles market. The project was well documented in these pages (RWEE, June 12, 2013).

The phasing and coupling system were designed and manufactured by the good people at Kintronic Laboratories. Installation and tune-up were a snap except for Tower 2, which had a very low driving point impedance, on the order of 2 –j20 ohms. To pull that driving point up to something reasonable, we used an inductor in shunt across the antenna tuning unit (ATU) network output. Getting that inductor and the rest of the network tuned up took considerable effort, trial and error. In other words, it was not your run-of-the-mill matching network.

For the first year of operation, all was well with the antenna system, but we eventually began to see some drift in the phase of Tower 2, just a degree or so between low (night) and high (day) power. Over the next year, the drift gradually worsened until we were seeing almost 6 degrees of drift. We had to set the phase to the licensed value plus 3 degrees during high-power operation to make sure it did not go below licensed value minus 3 degrees at low power.

This change in Tower 2 phase would occur gradually after changing power, giving the impression that it was the result of the slow heating or cooling of a component with RF current that was causing the change. Further, there was very little in the way of current amplitude change with the drift, and none of the other array parameters moved with the Tower 2 shift. That really cemented that the issue was local to the Tower 2 circuit branch.

In an effort to isolate the component responsible for the drift, we tried several things. First, with the system stabilized at the lower end of the drift at low power, we tried gently heating various components in the Tower 2 branch with a heat gun. That produced no results. Then we put a small space heater in the ATU cabinet and set it to 85 degrees or so. Again, no change. We tried moving coil straps around a bit and rocking/tightening coil taps. Still nothing.

No components showed signs of excessive heating. The plating on the coils was all still shiny and none of the capacitors was more than 10 degrees or so above ambient. It was a mystery.

There isn’t a lot that can go wrong with an inductor — it generally works or it doesn’t, and if there is a problem, it will usually manifest itself with discoloration from heating or will show up when rocking a tap or tightening a connection. So my focus was on the capacitors in the system.

Tower 2 in the KBRT array is the low-power tower, with only about 2.5 kW at full power. All the capacitors in the rest of the array were vacuum caps, and even the caps in the Tower 2 branch in the phasor were vacuums, leaving just four mica capacitors in the Tower 2 ATU. I thought it had to be one of those, but which one? One of the micas was in series with the input leg. The other three were all in parallel with one another and in series with the shunt leg to ground (paralleled to get the required current rating).

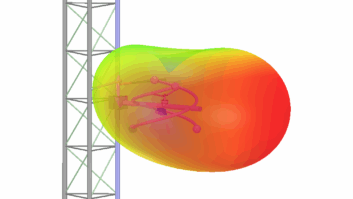

As I was pondering the situation, it occurred to me that a computer circuit model might provide some insights as to the effects of changing component values on the phase shift through the ATU network. With that in mind, I constructed a nodal circuit model of the ATU network, starting with a current source at the network input and terminating into a resistance that had resistance and reactance of the nominal driving point impedance of the tower.

One at a time, I changed the capacitor values up and down by the amount of the value tolerance shown in the capacitor manufacturer’s catalog for each, running the model after each change and noting the change in the current amplitude and phase through the network. The results were a little disappointing. I had hoped to find a “smoking gun,” but instead I got just small changes that in no way resembled what we were seeing in the field.

Then it occurred to me that the issue might be more complex than the single ATU network. What was happening to the input impedance of the network with the component value shifts, and what effect was that having upstream? To find out, I would need a model of the entire phasing and coupling system, not just the single ATU.

That took a lot more doing. The ATU networks, transmission lines and phase shift networks were easy. The power divider (PD) networks, not so much. I was able to calculate the PD reactances, but it took a lot of trial and error in the model to get the power divider components set right so that the correct currents and phases were produced at the ATU network outputs. I eventually nailed it and had a model that matched the calibrated antenna and base region models that I used in the method-of-moments license application.

With that done, I went back to varying the values of the capacitors within their rated tolerance and monitoring the current amplitude and phase at Tower 2 as well as the other towers. When I changed the Tower 2 ATU input leg capacitor by a few percent, I got a big swing in output phase and a negligible change in current amplitude. I also noted that there were no appreciable changes in the other array parameters.

Just to be sure, I also changed the values of the shunt leg capacitors to see what would happen. That produced an observable change in current amplitude, but did not produce the phase change that we are seeing in the field. That was not unexpected.

Based on the results of the models, I ordered a 2,000 pF fixed vacuum capacitor to replace the 0.002 uF 294 mica capacitor in the Tower 2 ATU network input leg. Our friends at Kintronics provided us with an insulated mount for the vacuum cap so it would fit the same holes as the insulated mount for the mica cap. That made replacing it a snap.

As soon as we replaced the capacitor, we saw a 9-degree shift in the Tower 2 phase on the antenna monitor, an indication of how far off the nominal value that mica capacitor was. It was no problem to bring the phase back to the licensed value with the phasor control (we had been chasing it with that control all along). Since then, the drift has been gone.

Would we have found the cause of this phase drift without using circuit models? Yes, we undoubtedly would have — eventually. The models definitely reduced the amount of time it took to isolate the problem and deal with it, and it saved us the trouble and expense of “shotgunning” the system (i.e., throwing parts at it until we found the culprit). It also gave me a much better understanding of the behavior of the system and the networks within it.

In this case, I used the WCAP Pro nodal analysis program from Westberg Consulting. This program is made for AM broadcast and is a primary tool I use for system design as well as moment method modeling (to account for the current phase and amplitude shift across base-region reactances).

Model construction in WCAP couldn’t be any easier — click-and-drag. Values are set by double-clicking on the component and filling in the fields. WCAP Pro is a bit pricey, but it’s worth every penny if you’re doing much of this kind of thing. In this case, it more than paid for itself because it saved me the cost of a trip to the west coast and no telling how much in unnecessary replacement vacuum capacitors.

There are other programs out there that will work, including the freeware LTspice analog circuit simulator. Using non-AM-specific programs may require a bit more work to create the model, but they generally will work.

When dealing with a multi-tower directional array, my advice would be to model it all as a system rather than modeling individual networks separately. As was the case here, it was the impedance shift produced by a drifting capacitor that caused the phase shift to occur way back upstream at the power divider. Modeling the network by itself did not reveal the problem.

Circuit modeling can be an excellent way of helping engineers narrow down the likely cause of some antenna system problems. The key is accuracy in creating the model and a good eye for interpreting the results.

W.C. “Cris” Alexander is director of engineering at Crawford Broadcasting Co. and a longtime Radio World contributor.