The author is southwest tech engineer for Wheatstone Corp.

Hardly a week goes by that the Wheatstone Tech Support department doesn’t get at least one call from a customer who is having equipment issues due to a lightning strike or power surge.

While it may not be possible to eliminate damage caused by electrical events such as these completely, there are some best practices you can implement in your new studio build (or even in your existing facility) that can minimize the likelihood of consoles or other audio equipment being destroyed by the electromagnetic pulse that results from these events.

Lightning and power surges create short but powerful over-voltage conditions in your electrical systems that can damage sensitive equipment. Replacing or repairing the equipment can be expensive but may seem minimal compared to the loss of revenue if you are taken off the air.

Here are a few things you can do to protect your gear and keep your stations on the air.

Use a UPS

An uninterruptible power supply can go a long way toward protecting your broadcast gear from power surges. It has the added benefit of keeping you up and running during short-duration power loss events as well.

You can protect each studio and your TOC area by installing small UPS units to power each cluster of critical pieces of equipment, but having units scattered around your plant means you need to have a strategy for ensuring that the batteries in those units are replaced regularly, before they start to go bad. Make sure any UPS units you use power the load off the batteries, isolating your gear from the AC mains.

A better, albeit more expensive, option would be a large UPS system that can power your entire TOC and studio core. This is easiest to implement when you are planning a build and might be worth pitching to the decisionmakers as a necessary, integral part of your new plant.

Implement a strategy

UPS systems alone are only part of the solution. A good grounding scheme can go a long way to protecting your expensive studio gear from the destructive force that is packed in every lightning storm that comes your way.

Wheatstone’s Jeff Keith says, “Grounding in a broadcast facility is more or less a science. But there are some pretty good ground rules (pun intended).” Here are a few of his suggestions:

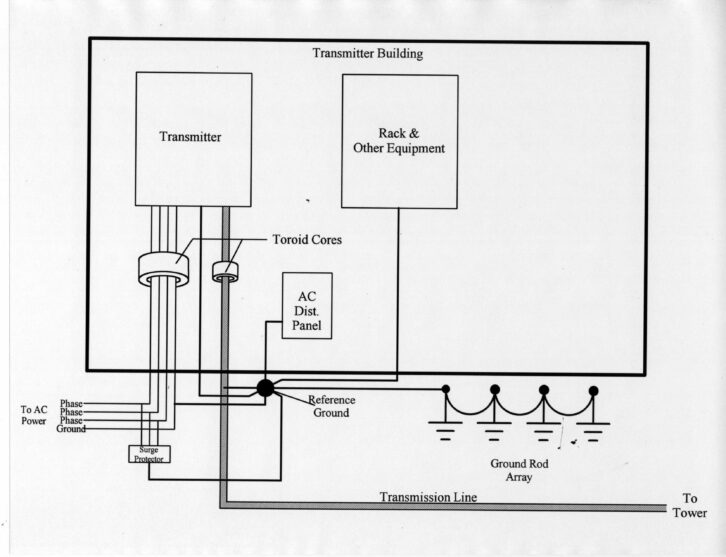

Use a single-point ground, also called a “star” ground system because everything comes back, as much as possible, to a single earth-ground point. See Fig. 1.

“The worst possible condition is for surges to have more than one destination because that usually means there’s some piece of broadcast gear ‘in the middle,’” says Jeff.

“Temporary (surge-related) voltage differences between AC and audio ground are the cause of most of the failures that we see here at Wheatstone. A thousand-amp surge across an ohm of ground causes a kilovolt voltage drop.”

Additionally, you will want to use a large conductor for grounds. It might not be easy pulling a 2/0 or 3/0 copper conductor through your house cabling conduits, but the benefits of a properly designed ground system will pay off big dividends the first time a lightning strike finds that the easiest way through your system is straight to ground. (At transmitter sites you will probably want to use ground straps of at least 2 to 4 inches in width, due to the high RF fields in play.)

“Today we have shielded network cables, too, so there’s another ‘wire’ to consider. And even though network interfaces are transformer-coupled, those transformers are little tiny guys with not much of a ‘gap’ for a 10 to 20 kV wallop. I’ve seen cases where an incoming surge jumped right across the transformer and found its way into the Ethernet switch’s silicon guts and yes, the magic smoke got let out.”

Don’t neglect proper grounding and bonding at the studio. Just because you may not have a 1,500-foot tower in your backyard doesn’t mean you are immune from lightning damage. Do your research and spend the time and money needed to implement a good grounding system at your studio — whether it’s a new build or an existing plant — as well as your transmitter site locations to protect your investment and revenue streams.

[Check Out More of Radio World’s Tech Tips]

Planning a build?

When building a facility from the ground up, you have a one-time opportunity to create the best ground system you can.

We asked Jeremy Hewitt, senior systems engineer for Inrush Broadcast Services, for his thoughts on facility grounding. He recommends the Ufer ground for new facilities.

“A Ufer ground typically consists of steel reinforcing rod (rebar) directly embedded in concrete. It must be at least 20 feet long, but it is not required to be continuous. If it is not continuous it is permissible for it to be joined via tie wires, welding or exothermic welding. An alternative means of constructing a Ufer ground would be to embed 4 AWG bare copper wire in the concrete.”

Fig. 2 shows a Ufer ground at a broadcast facility. The Ufer ground system is named after Herbert Ufer, a former U.S. Army consultant. He was tasked with creating an effective and relatively inexpensive grounding means for bomb storage vaults in Arizona.

Due to the dryness of the soil, a ground rod might have to be 100 feet long in order to meet the low resistance requirements, which was not cost-effective or practical.

“In order for a Ufer ground to be effective,” says Jeremy Hewitt, “the concrete must remain in direct contact with the ground. This means that vapor barriers or thermal insulation must not be installed beneath the slab or foundation. Typically, a Ufer ground produces a resistance to ground of 2 to 5 ohms.”

Optimizing for an existing building

Of course, the Ufer grounding method is only practical when established as part of a new installation.

In lieu of a Ufer ground, multiple ground rods can be used to ensure that a low-resistance path to ground is maintained. Ground rods should be driven into the soil at least 8 feet unless impossible due to encountering rock.

A ground ring in which at least 20 feet of bare copper wire (2 AWG or larger) surrounds the structure and is in direct contact with the earth is another option to ensure a low-resistance path to ground.

Regardless of the type of grounding electrode, the resistance between the electrode and the earth should not be more than 5 ohms. If multiple ground rods are used to achieve this, they should be spaced by half the length of the longest ground rod, for maximum effectiveness. If multiple grounding electrodes are used to lower the resistance, they should be bonded together. In addition, there should be a common connection where all electrical systems are bonded together to ensure that no potential can be created between the systems.

Without a suitable low-resistance facility ground, it is likely that a lightning transient will create a potential high enough to render any built-in transient protection ineffective.

Ideally, an effective facility grounding system would be used in conjunction with an overall surge protective device such that a low-resistance discharge path is created for the surge protective device.

Stay grounded

Grounding for your studio or transmitter facilities should never be an afterthought. You have hundreds of thousands of dollars’ worth of high-tech audio, video and RF equipment that depends on being well-grounded for its protection. Lightning strikes and electrical power surges are facts of the engineering life, and as the engineer designing the facility, it’s your job to make sure the potentially damaging current has a better choice for where to travel when it comes to visit than directly into your expensive gear.

The author can be reached at [email protected].